Who’s Involved

With research commencing in 2024, the project is supported and partially funded by the U.S. Department of Energy’s (DOE) Vehicle Technologies Office (VTO) through the Office of Energy Efficiency and Renewable Energy (EERE). It is included among 45 projects across 18 states and Washington, D.C., receiving funding to advance research, development, demonstration and deployment in several areas critical to reducing greenhouse gas (GHG) emissions in the transportation sector.

The hydrogen-hybrid power demonstration project is the latest in a series of initiatives that builds upon our 35 years of enterprise experience in hydrogen fuels.

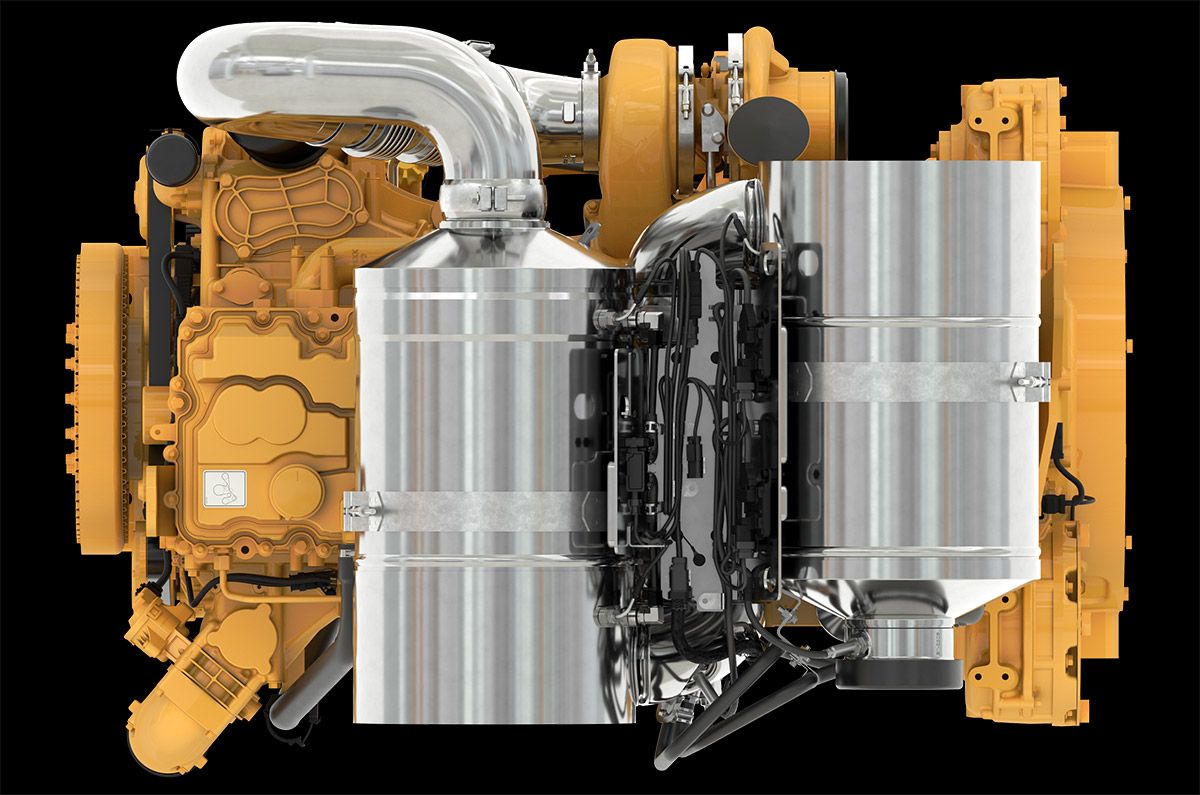

“Every off-highway application has its own unique duty cycles, lifecycle demands and performance expectations, and this complexity is driving the development of a wide range of power solutions for the energy transition,” said Steve Ferguson, Senior Vice President at Caterpillar Industrial Power Systems. “One size does not fit all, which is why we’ve engineered flexibility into the C13D engine to serve as our platform of the future.”