Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

2D OR 3D GRADING SYSTEMS: HOW DO YOU KNOW WHAT

YOU NEED?

Grading technology is getting plenty of buzz these days. People who use it swear by the benefits.

No doubt about it—this technology can help you make more money.

But when there are so many options available, choosing the right system can be confusing. If you’re considering an investment in grading technology, take a minute to learn the basics. A quick review of the fundamentals will help you make the right decision for your business.

What do these systems do?

Cat® GRADE technologies perform two key functions.

- Some GUIDE operators to grade visually—showing where to cut and fill and giving feedback along the way

- Some CONTROL the blade or bucket automatically—eliminating or greatly reducing manual effort

- Some do both.

Your Cat dealer will help you select a system with the functions you need.

So what’s the payback?

Every situation is unique, but studies show Cat GRADE technologies can improve productivity by up to 50%—and pay for themselves in about 6 months.

2D vs 3D: What’s the difference?

2D SYSTEMS |

3D SYSTEMS |

|---|---|

| Work on flat planes and slopes | Work on planes, slopes, contours & comple curves |

| Use an external point of reference (stringline, curb or laser) | Use an internal point of reference (digital design plan) |

| Use one or more of these sensing technologies: slope, rottion, sonic, laser | Use one or more 2D senors + GPS/GNSS receiver or Universl Total Station |

| Cost less than 3D | Cost more than 2D |

| Require less infrastructure (no additional surveyoers, design managers, base stations or data radios) | Require additional infrastructure (people, base stations, data radios) |

| Work well when job conditions and applications rarely change | Work well when job conditions and applications are always changing |

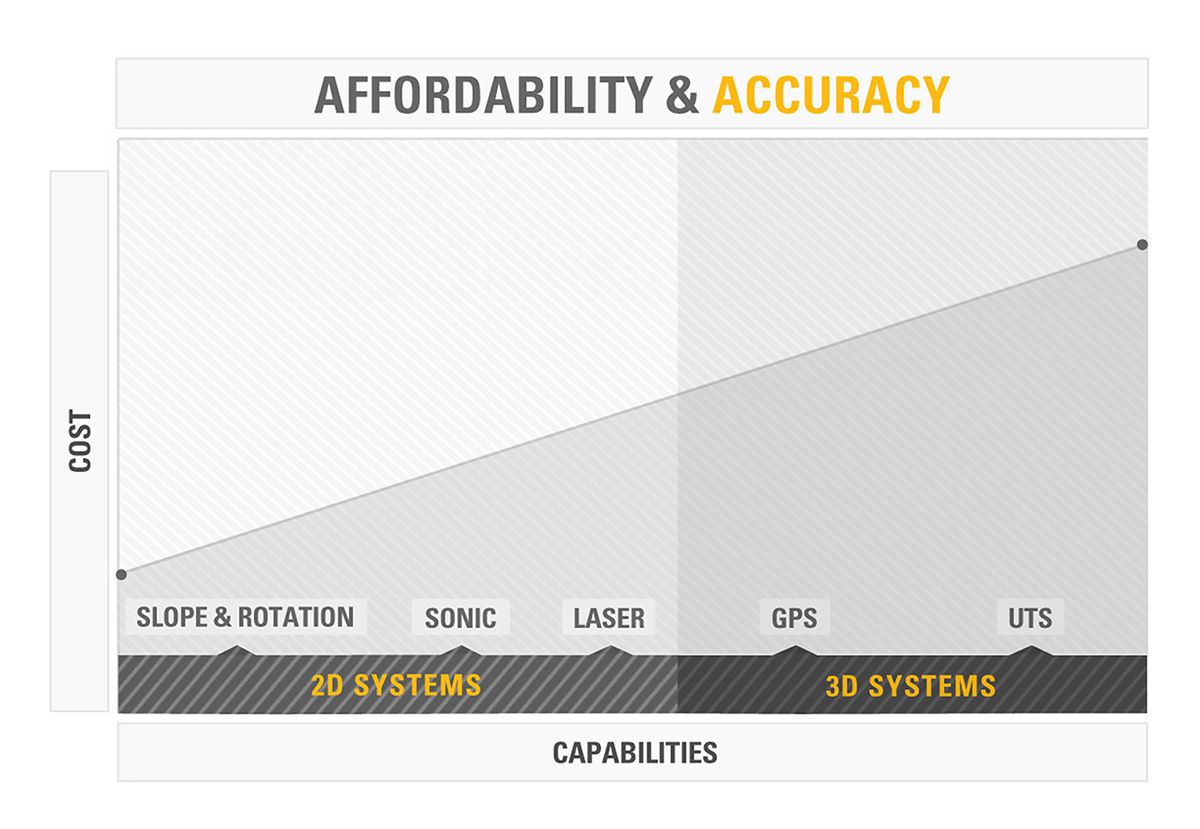

Don’t assume you need 3D

You may depend on GPS for driving directions, but that doesn’t mean you need it on your dozer. 2D systems are simple, less expensive and easily upgraded to 3D. So before you make any decisions, talk it over with your Cat dealer.

Rule of thumb: the more capabilities a system has, the higher its price tag will be.

Sensors at a glance

|

|||||

| Each system, whether 2D or 3D, is built with a variety of sensing technologies. | |||||

2D Systems |

|||||

Type: |

Control Blade/ Bucket With: |

Typical Uses: |

|||

Slope |

Slope or angle information | Motor grader blades Dozer blades |

|||

Rotation |

Rotational Information | excavator buckets Motor grader circles |

|||

Sonic |

Time and speed of sound calculations | Motor grader blades Pavers and cold planers |

|||

Laser |

Laser light | Motor grader blades Dozer blades Excavator buckets |

|||

3D Systems |

|||||

GPS/GNSS |

Positioning satellites | Motor grader blades Dozer blades Excavator buckets Scraper bowls |

|||

UTS |

Robotic device that tracks a machine-mounted prism | Motor gradaer blades Dozer blades Excavtor buckets Pavers and mills |

|||

*What’s GNSS?

Most people use the term “GPS” to describe the space-based navigation system that’s all but replaced the paper map. But to be perfectly accurate, GPS refers to the US system of satellites only. The worldwide network is called GNSS (Global Navigation Satellite System). It includes:

- GPS (USA)

- GLONASS (Russia)

- BeiDou (China)

- Galileo (EU)

Factory-integrated or dealer-installed?

Another choice to make with help from your Cat dealer.

Factory-Integrated (Cat® Grade) |

|---|

| Integrated design |

| Built into your machine |

| Limited portability |

| More component protection |

Dealer-Installed (CAT® ACCUGRADE) |

|---|

| Cat-branded aftermarket option |

| Optimized for your machine |

| Maximum portability |

| Less component protection |

It's a big decision. Your dealer can help.

If you’re in the market for a grading system, have a conversation with your Cat dealer. Together you can explore all the factors that affect your decision.

- Job requirements

- Site conditions

- Application issues

- Budget priorities

- Fleet size and makeup

- Skilled workforce availability

- Contractor-subcontractor relationships

- Future plans

Whether you choose 2D or 3D, factory-integrated or dealer-installed, you can be sure this technology will help you improve safety, productivity and profitability.

RELATED ARTICLES

You’re here to get ideas to grow your business. Read on for machine insights and expert tips and tricks to get more out of every job.

-

Machine Control & Automation Can Add To Your Bottom Line

Technologies that enhance machine performance can add to the bottom line.

Learn More -

Automation & Autonomy: What's the Difference?

These words get used interchangeably, creating confusion. To improve consistency, we've defined these terms.

Learn More -

Paving Production Calculator App

This calculator can help optimize the jobsite, reducing inefficiency and contributing to smoothness.

Learn More -

Productivity - More Efficiency. Better Results.

Cat® Technologies gives you the accuracy, consistency and productivity you want.

Learn More