Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Get the Most from Your Machines with Telematics

Dani Watson | Construction Marketing Consultant

No matter the size or age of your fleet, it’s important to maximize machine efficiency while minimizing safety hazards on the job. But how do you know whether your machines are experiencing unexpected downtime or being operated unsafely? That’s where telematics, or the use of technology on machines to collect data about performance, comes into play. Because adding this hardware to your machines is an investment, knowing exactly how to use it beforehand is key. We sat down with Matthew Hendry, Caterpillar Technology Field Support Specialist, to learn more about how a telematics system can boost your job site productivity.

Matthew’s Usage Guide for a Fleet Telematics System:

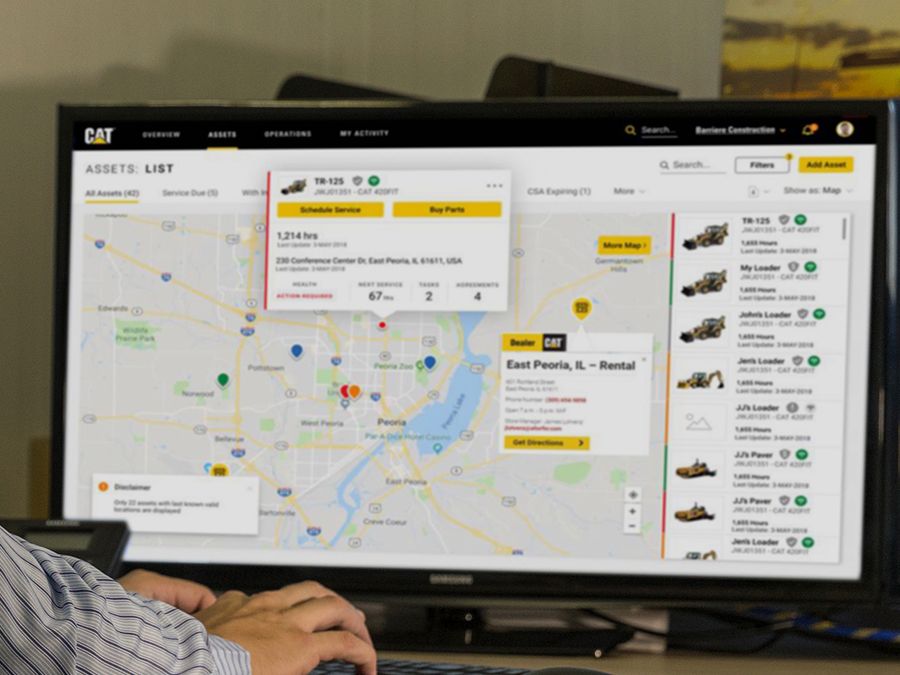

- Preventative maintenance. The best way to ensure that your machines experience no unexpected downtime is by using telematics data to perform preventative maintenance. By using tools like the Cat® Inspect app or VisionLink® software, you can schedule maintenance around project deadlines and send reports and alerts to the appropriate parties without delay so that maintenance isn’t missed.

- Correct operator behaviors. Telematics devices also provide valuable insight into operational efficiency. To make sure that operators are using the equipment appropriately, you can use telematics to receive alerts when they are doing things like coasting in neutral, not wearing seatbelts, or pushing the machine into engine overspeed. Identifying where and when these behaviors occur can be turned into a training opportunity for machine operators. You can also use this data to set a benchmark for performance and, once your operators are given training, compare the number of alerts to that benchmark to see if there is a reduction.

- Improve decision-making. Let’s face it: no one likes paperwork. By using fleet management software, you can both reduce paperwork and create more thorough, searchable record keeping. With the Cat Inspect app, you can perform machine inspections and send them to the appropriate people without lots of manual paperwork to fill out. This allows for any action items to be addressed immediately, which increases safety and machine efficiency and solves issues in a timely fashion.

How Telematics Provides Real-World Results

Telematics can provide insight into how your fleet performs but is it really as useful as it seems?

Copart, an auto remarketer, would say so. After experiencing measurement issues with their first telematics system, the company introduced some Cat® 938k loaders to their fleet of over 500 units, which came equipped with telematics devices that could be configured specifically for salvage yard usage.

“After just six months…here’s where we ended up: an almost 10% reduction in idle time [and] a savings of 0.4 gallons/loader/hour in average fuel burn rate,” said Joe O’Leary, Director of Equipment, Safety and Environmental Compliance at Copart.

“I showed our executive team how it would work if we applied the same savings to all 500 loaders in the fleet,” noted O’Leary. “The savings in idle time alone were about $3.5 million.”

Can Smaller Operators Benefit from Vehicle Telematics Systems?

It’s not just large operations that benefit from fleet telematics systems either: smaller operators can still adopt these solutions, and will find that the preventative maintenance aspect is especially useful for productivity improvement. For those with 1-5 machines, telematics can make preventative maintenance more predictable. And as smaller operators begin to grow and can’t be physically present at the job site, they can take full advantage of this data to see when machines stop, start and idle.

What if you have a mixed fleet? You can install Cat telematics devices on competitive equipment to capture data and perform maintenance. What data you are able to gather, however, will really depend on the age and size of each machine.

So how do you get started with a telematics program? Your first step is to contact a technology specialist at your local Cat dealership – they can work with you to develop a plan and determine a goal for your data usage. Start small in your telematics program with one to two key elements you’d like to improve in your operations and expand once you’ve achieved those goals.

A telematics program can be an excellent way to gain more insight into your machines by increasing productivity and utilization and improving safety and performance. While the initial onboarding process requires some investment, it is more than worth it when it comes to the lifespan of your fleet. To get started with your own fleet telematics program, contact your local Cat dealer.

DANI WATSON

Construction Marketing Consultant

Certified in 6 Sigma Black Belt and Change Management, Dani Watson not only helps manage projects efficiently within Caterpillar, but is an expert communications strategist for Caterpillar’s marketing communications needs.

RELATED ARTICLES

You’re here to get ideas to grow your business. Read on for machine insights and expert tips and tricks to get more out of every job.

-

Cab Technology Helps Boost Productivity

New cab technology in your Cat machine is designed to help you be more productive, work more efficiently and be less fatigued.

Learn More -

New Construction Technology To Help Your Business

Learn how construction trends like new technology can help grow your business.

Learn More -

How to Use Drones on Construction Job Sites

You can use drones in construction for a wide variety of things, and with the right planning and drone program can give your business detailed, accurate, and real-time information on your site’s progress. This is information you can put to use to improve the quality, accuracy, and efficiency on the job.

Learn More -

On The Level: Construction Blog

Get key industry insights, tips and updates from Caterpillar product experts and industry professionals in our On The Level Construction Blog.

Learn More

Connect with Us

In person or online, we're here to help you find the answers you need. Reach out to your local Cat dealer for advice close to home. Sign up for our newsletter to hear from industry experts. Or keep exploring this site for additional information.