Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Finding Skilled Equipment Operators

One of the biggest challenges you face as a contractor is finding skilled equipment operators. It’s always better to retain skilled workers than it is to constantly train new ones. It's a challenge you should take seriously because finding qualified workers will ultimately save you time, money and headaches.

Estimated read time: 5 minutes

Chances are, you need to find skilled equipment operators — and fast. If you're always in the process of searching and accepting applications, your current team is likely picking up slack or doing extra work. That’s never good for crew morale.

Employing skilled operators can make your business more profitable because experience, intuition and know-how are invaluable on a jobsite. Good operators work more quickly and efficiently, while causing less wear and tear on your equipment. You’ll get more done every day and end up spending less on service and maintenance. Bottom-line benefits, indeed.

Efficient operation saves on fuel costs as well. Research shows that a skilled operator can use 10-12% less fuel every day than an unskilled one.

And never discount safety. Experienced operators have seen the mistakes that can happen on a jobsite. They’ve probably learned from a few of their own, too.

All those reasons are probably why, when Caterpillar asked a group of heavy construction professionals to identify their biggest source of competitive advantage, more than 30% said skilled operators.

SURVEY RESULTS

Skilled operators can make or break your business, so attracting them should be a top priority. Unfortunately, it can also be a huge headache.

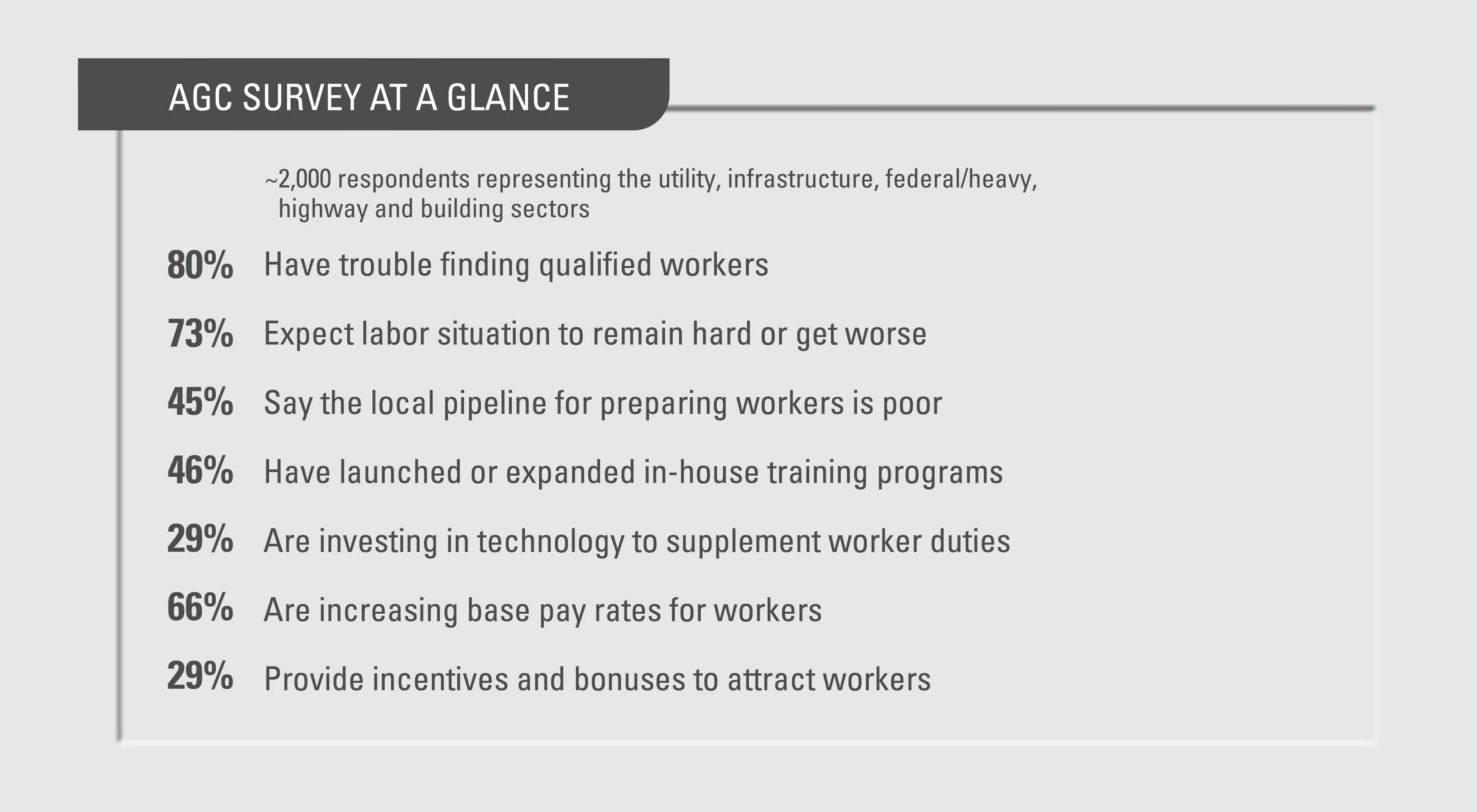

In a 2019 survey of U.S. construction firms by the Associated General Contractors of America (AGC), 80% of respondents said they struggle to find qualified employees to fill their hourly positions. Most participants predicted the skilled labor shortage would continue, with 73% saying it will “continue to be hard” or “get even harder” to find workers in the immediate future.

A skilled labor shortage can cause lots of negative consequences. You may find it challenging to pursue new business, meet project deadlines or hold the line on costs — especially fuel costs — if your operators are not highly experienced.

WHAT CAN YOU DO?

There’s no one way to build a strong team, but if you’re struggling to meet staffing requirements, two of the first things to look at are compensation and culture.

- Compensation trends

When the economy collapsed in 2008, construction wages dropped, causing skilled workers to either retire or leave the industry for higher paying jobs, particularly in oil and gas.

Pay scales are now moving back toward historical levels. The AGC says 66% of companies responding to its survey were increasing base pay rates for workers, and 29% were providing bonuses and incentives to attract employees. Make sure you’re keeping pace.

- Build a collaborative culture

Assuming you’re compensating people competitively, the other big deal-breaker for many employees — particularly younger ones — is culture.

Culture is a complex topic, but the essentials are fairly simple. People want to work where they feel safe, respected and appreciated. They value capable leadership, committed co-workers, access to information, opportunities for personal growth and input on decisions that affect their work lives. Fostering this kind of culture will put you in a stronger position to compete for scarce labor.

THREE ADDITIONAL EFFECTIVE STRATEGIES

Here are a few ideas for demonstrating a solid commitment to your incoming (and current) workforce.

1. Invest In training

The American Society for Training and Development (ASTD) says training is one of the most effective ways to attract top people. It’s also a means to improve productivity and control costs, particularly fuel costs. The ASTD recommends 40 hours of training per year per employee.

While that may sound daunting, remember that training can include low-cost things like lunchtime coaching sessions and on-the job mentoring. Other effective options are classroom instruction, hands-on learning, online courses, offsite seminars and simulator-based training.

2. Run a newer fleet

If you had to choose between working all day in a brand-new, fuel-efficient machine or gutting out a shift in something built during the Reagan era, what would you pick?

If you’re having a hard time attracting equipment operators, give some thought to the “office” you’re asking them to work in. Maybe it’s time to upgrade some of the units in your fleet.

New machine features that attract operators:

- Easy-access cab

- Comfortable seat

- Automatic climate control

- Headroom, legroom

- Joystick controls

- Simple, readable displays and gauges

- Panoramic views

- Low sound levels

- Vibration dampening

- Bluetooth-enabled

3. Tempt with technology

Millennials and younger workers (those reaching adulthood around the year 2000 and after) became the largest segment of the labor force in 2016, according to the Pew Research Center. The greatest strength of these new generations, say many industry leaders, is their comfort with technology. Most have never experienced a world without computers, cellphones, tablets and smart watches.

While few among them may seem interested in earning a living as an equipment operator, it may be possible to change their minds. Introduce them to 21st-century machine technology like automated control and guidance systems, GPS-based management tools and now, remotely controlled equipment systems.

Remote control offers operators a more comfortable, safer and, some would say, more fun operating environment. Whether you choose a portable, line-of-site system or a fully remote sit-down control station, remote operation gets operators out of the cab and away from noise, dust, vibration and harsh conditions. It can be an attractive alternative to spending a long day in a machine cab.

Securing and retaining quality operators promises to be one of the toughest jobs you’ll face as a contractor in the coming years. But you now have more ways than ever to meet those challenges and even come out on top. Check out our Cat® webinars for more tips on cost-saving solutions.

Once You Own, You're In

Gain unlimited access to must-know information about your machine. Find ideas you can put to work on the job right away, including business insights.