Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

FINDING YOUR EXCAVATOR LIFT CAPACITY

Your Cat® excavator is occasionally called to perform some extremely heavy lifting applications. Sometimes, the weight of materials is so significant — and the lift requirements of your excavator so critical — that you may need to determine the size of your excavator based on this application alone.

Knowing the limits of your excavator is critical. But how is the lift capacity determined for your Cat® excavator?

Your excavator lift capacity is based on the machine’s weight, center of gravity, lift point position and hydraulic capability. It’s also limited by the excavator’s tipping stability and hydraulic capacity. You’ll need to be just as informed as the experts to select the right excavator for the job, which means understanding how to determine your excavator’s lift capacity and read the charts that give you this vital information. It’s easier than you think.

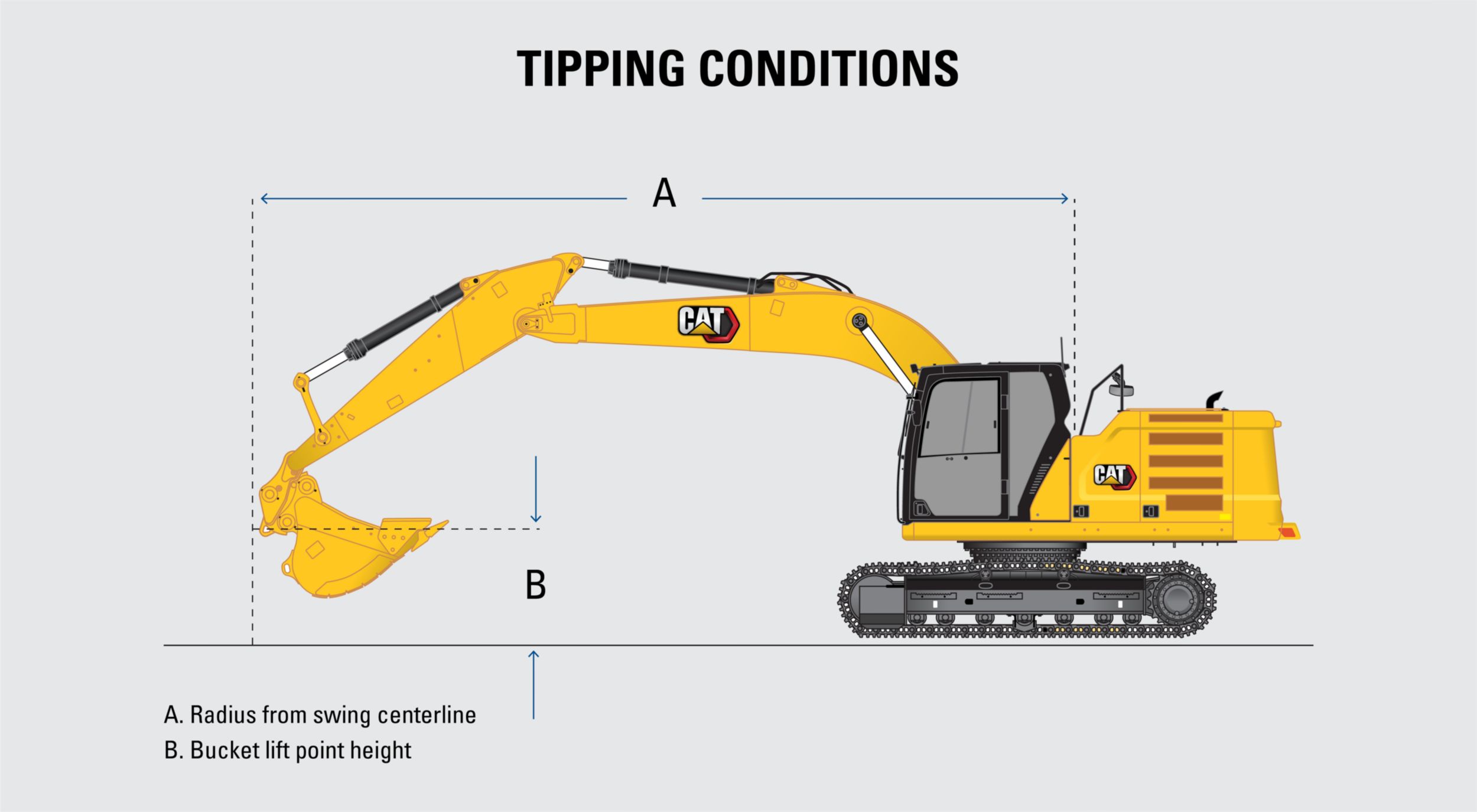

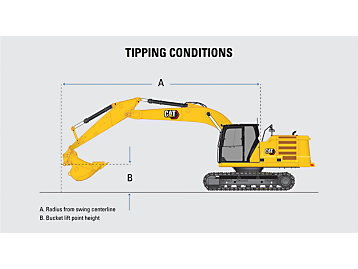

TIPPING STABILITY

Your excavator is at its tipping point when the weight in the bucket acting as the center of gravity causes the rear rollers to lift off of the track trails. A tipping load, therefore, is a load that brings your excavator to its tipping point at a specific radius. This radius can be measured from the axis of upper structure rotation to the center of the vertical load line — in other words, the radius from swing centerline (A). The height is based on the bucket lift point height (B) — the distance of the bucket lift point to the ground.

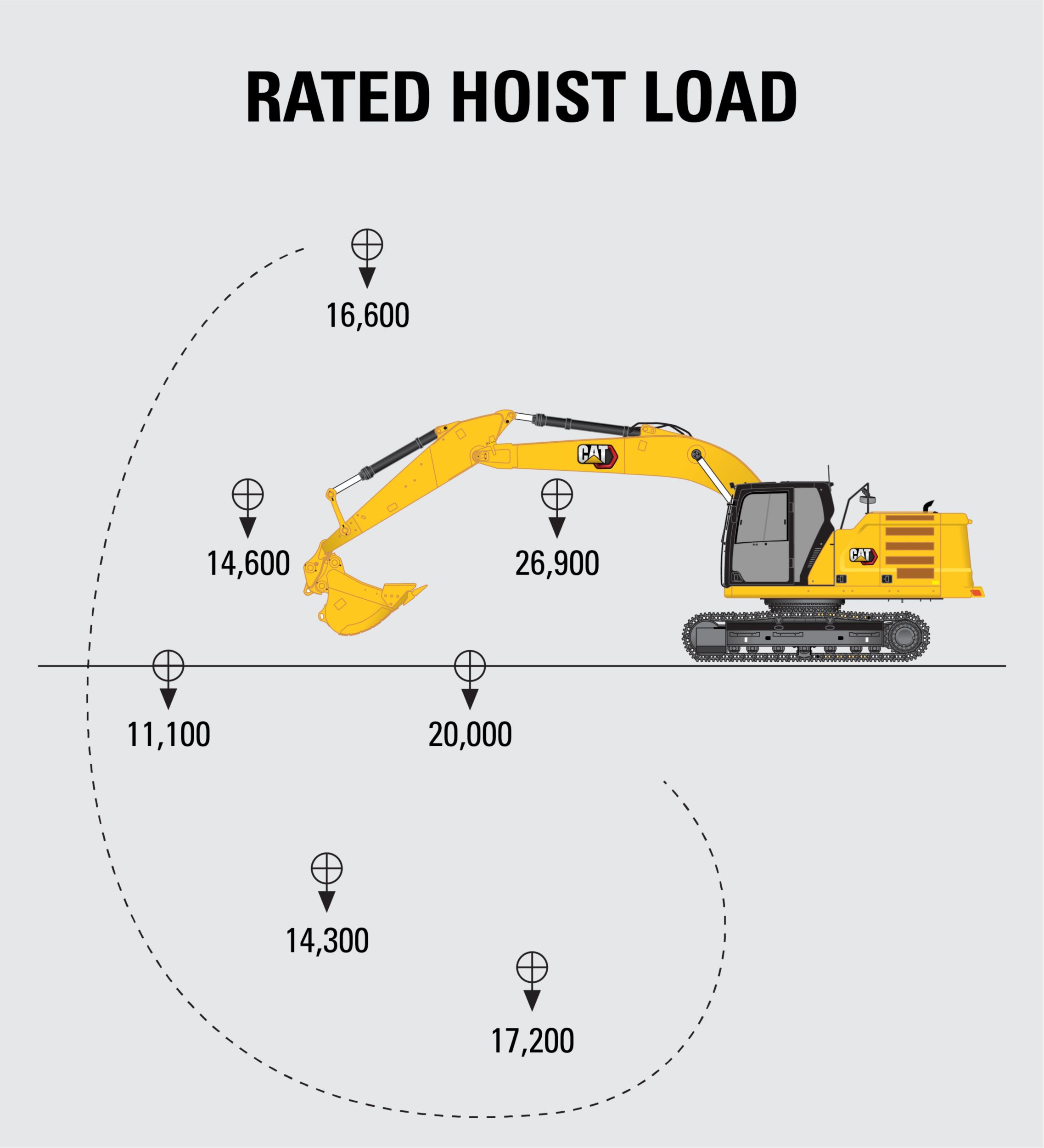

RATED HOIST LOAD

Calculate the rated hoist load of your excavator by using the vertical distance of the lifting point to the ground and the radius of the load. The rated load will not exceed 75% of the tipping load, 87% of the excavator’s hydraulic capacity or the machine’s overall structural capability.

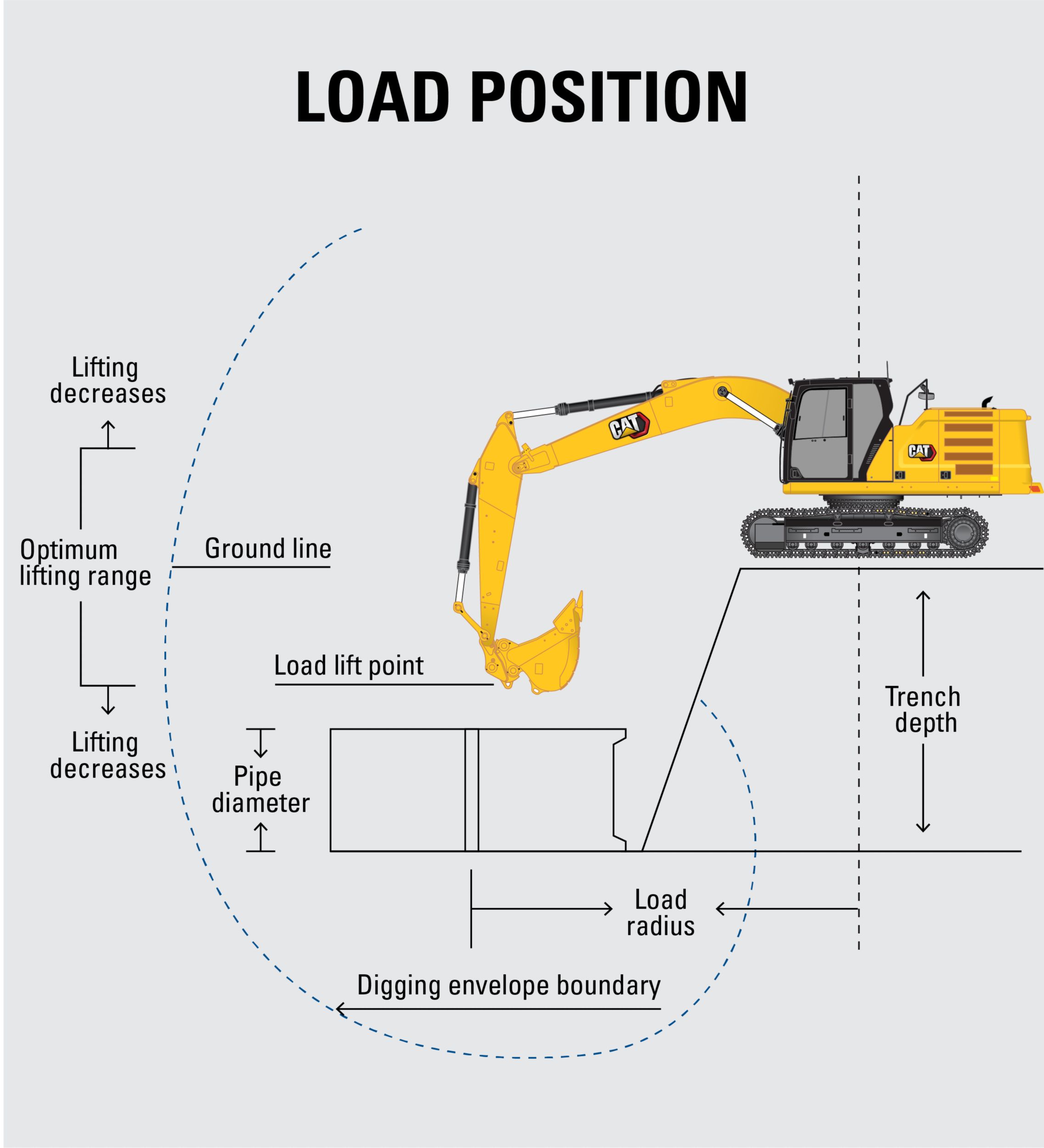

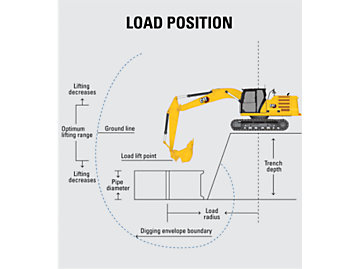

The lifting capacity of your excavator will vary based on the load position, as you see illustrated in these diagrams:

Lifting above ground? Get the load as close to the excavator as possible. Use a short cable and position the excavator to put the load lift point in the optimum lifting range.

Lifting below grade? Use a cable of sufficient length to position the load lift point in the optimum lifting range.

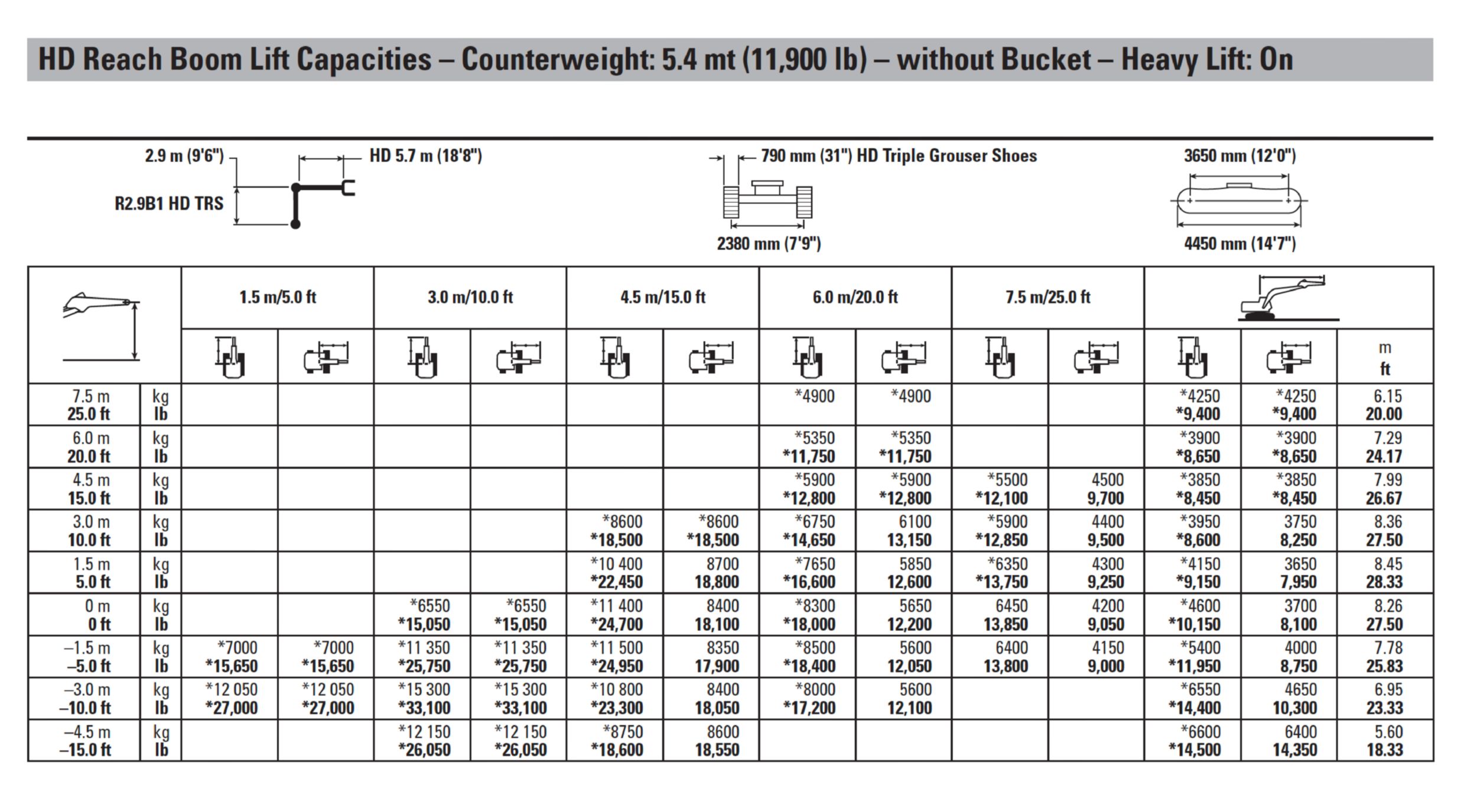

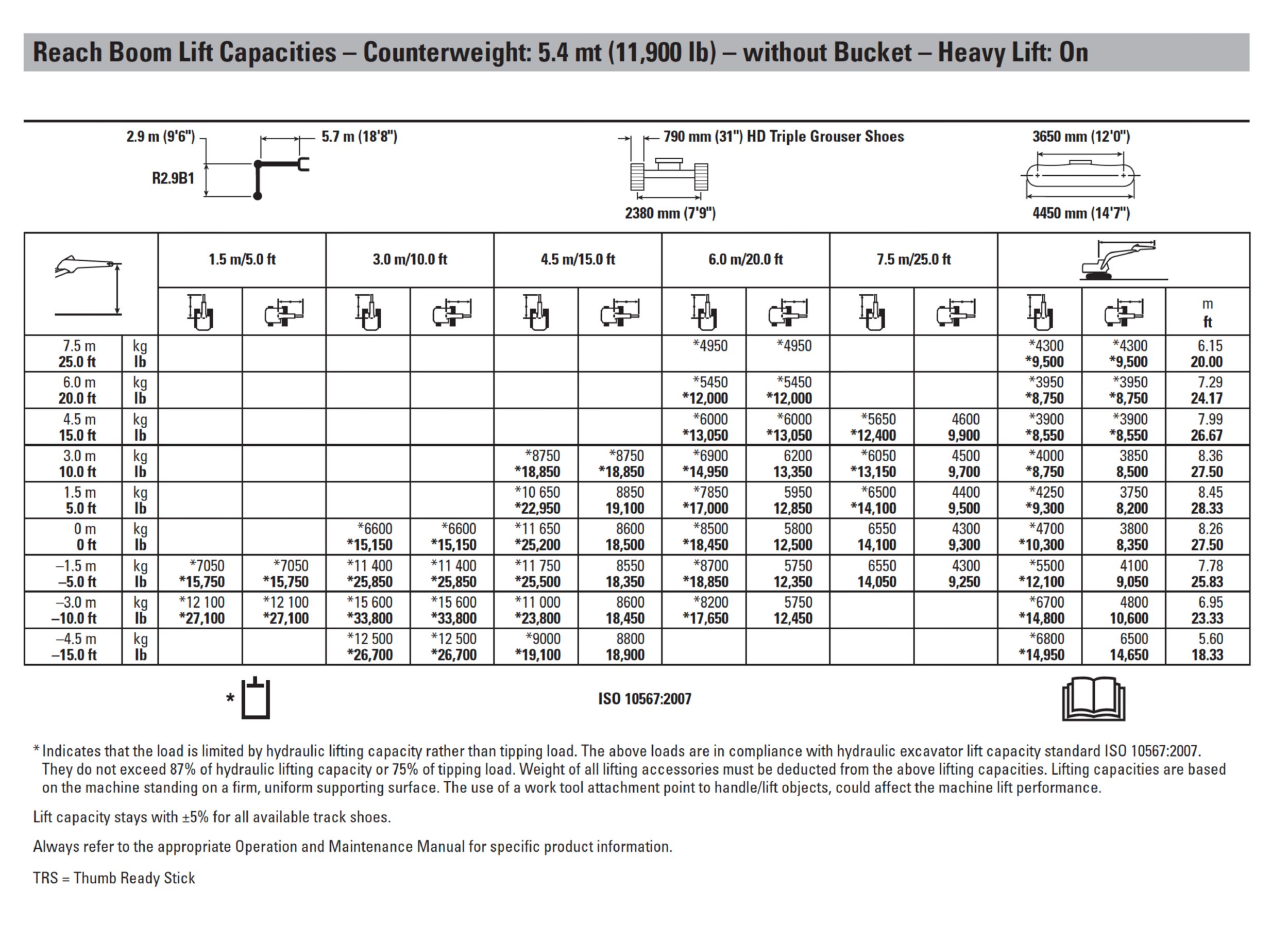

GET TO KNOW YOUR LIFTING CAPACITIES CHART

The following tables list capacities based on a lifting point at ground level. Lifting capacities are different for each machine and vary by machine configuration. For lifting capacities at other heights or with other tools, refer to the current specification sheets.

Determine your lift point height by considering how high you will need to lift your load. Determine the lifting radius from the centerline of the swing point. Then, find on the chart the cell where the lift point height and lifting radius intersect. The number you find in the cell is the rated lift capacity. If the cell is blank, your excavator cannot lift the load safely.

Popular Articles About Excavators

Get the most from your excavator with operating tips, safety advice, maintenance help and much more.

-

The "Value" in a Customer Value Agreement

Check out these 4 ways a Customer Value Agreement helps your equipment and your business.

Read Article -

Mobile Goes Mainstream

Cat mobile apps make it easy to track equipment location, use, health and more.

Read Article -

Your Equipment Is a Reflection of Your Brand

Keep your equipment in good running condition to maximize uptime and reduce operating costs.

Read Article -

Eight Ways to Attract and Keep Top Talent

Hiring and retaining workers can be a challenge. Use these tips find the people you need.

Read Article