Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

TIPS FOR DIGGING AND TRENCHING WITH YOUR CAT® EXCAVATOR

Learning best practices for digging with your Cat® hydraulic excavator can save you time and money. These basic tips for digging and trenching can help you get the most out of your excavator while staying safe , increasing efficiency and reducing fuel costs.

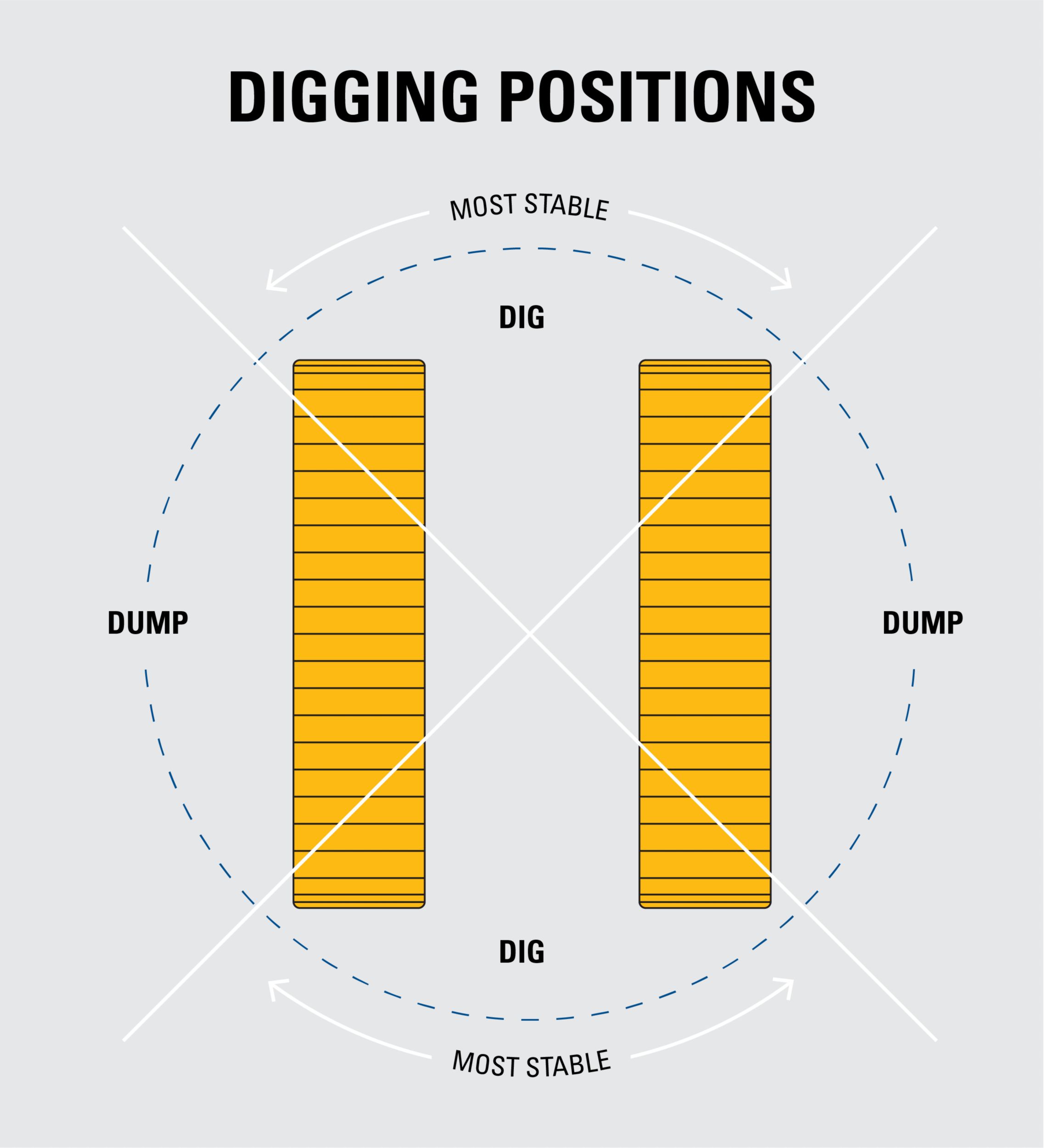

POSITIONING YOUR EXCAVATOR

The larger the platform on which your excavator sits, the more stable your machine will be. An optimum setup would allow you to dig to the front or the rear, then dump to the sides. This lets a truck or spoil pile to get close to the side of your excavator and cuts down on the distance of each pass, saving fuel.

Need to make repeated long reaches? The most stable positions to dig are diagonally across each corner of your tracks.

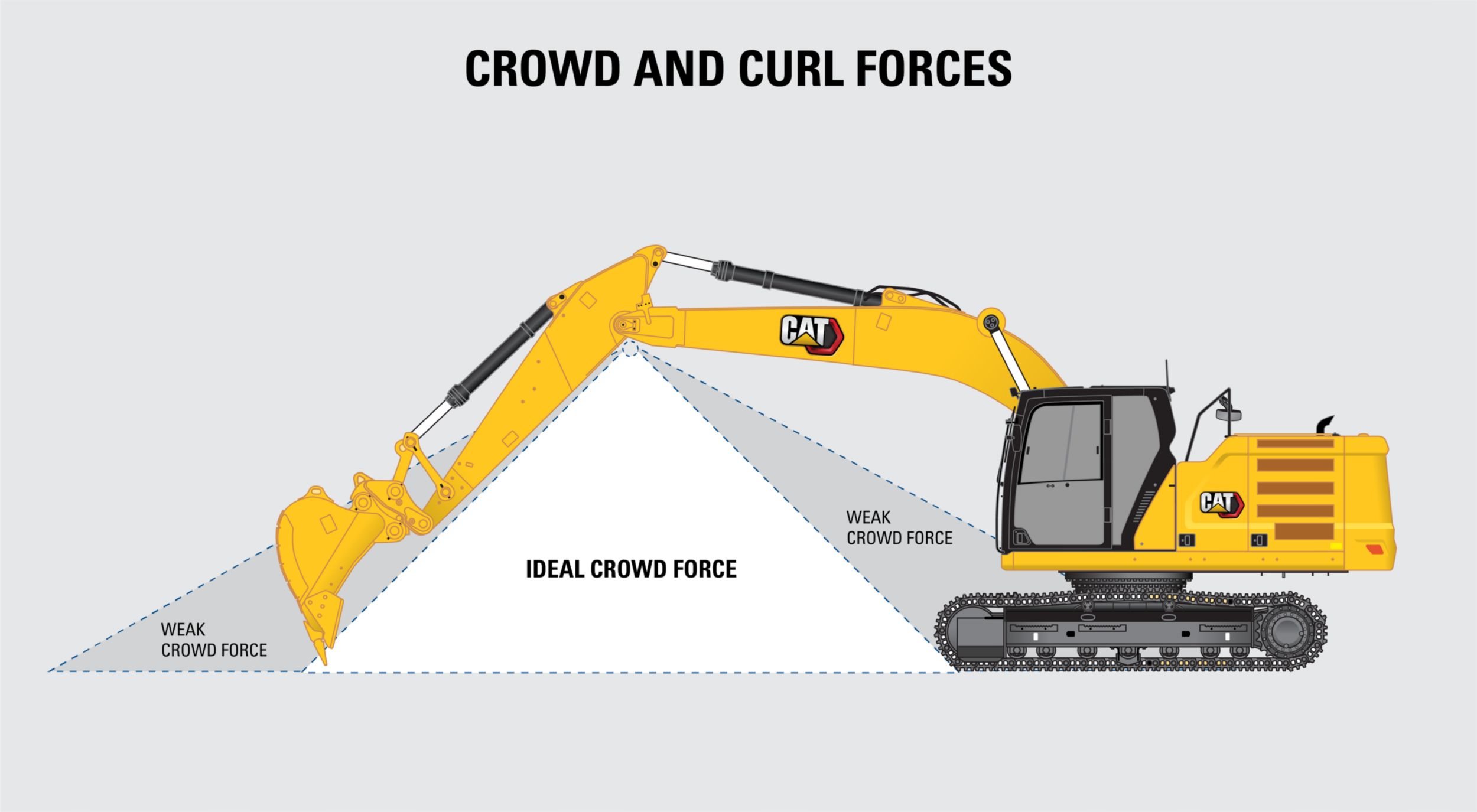

OPTIMIZING YOUR DIGGING RANGE

The optimal digging range for your stick starts about 35 to 45 degrees from vertical back to a vertical position. Digging outside this range lowers your efficiency, lengthens cycle times and may make your excavator’s position less stable.

Ideally, the bucket should be loaded by the time your stick returns to the vertical position. As you dig, continue to move the machine undercarriage forward (or backward) between passes to maintain this 35- to 45-degree range.

Use the stick crowd force and bucket curl force to give you breakout power without burning through additional fuel. Your stick crowd force is generated when digging by moving the stick inward. The bucket curl force is generated by the bucket cylinder and linkage. Ideally, the bucket curl force should be 10% to 15% greater than your stick crowd force to maintain good performance. That’s why bucket design and ground engaging tools can make a big difference in the performance of your excavator. Talk to your Cat® dealer about the buckets and bucket tips that might be best suited for your jobsite.

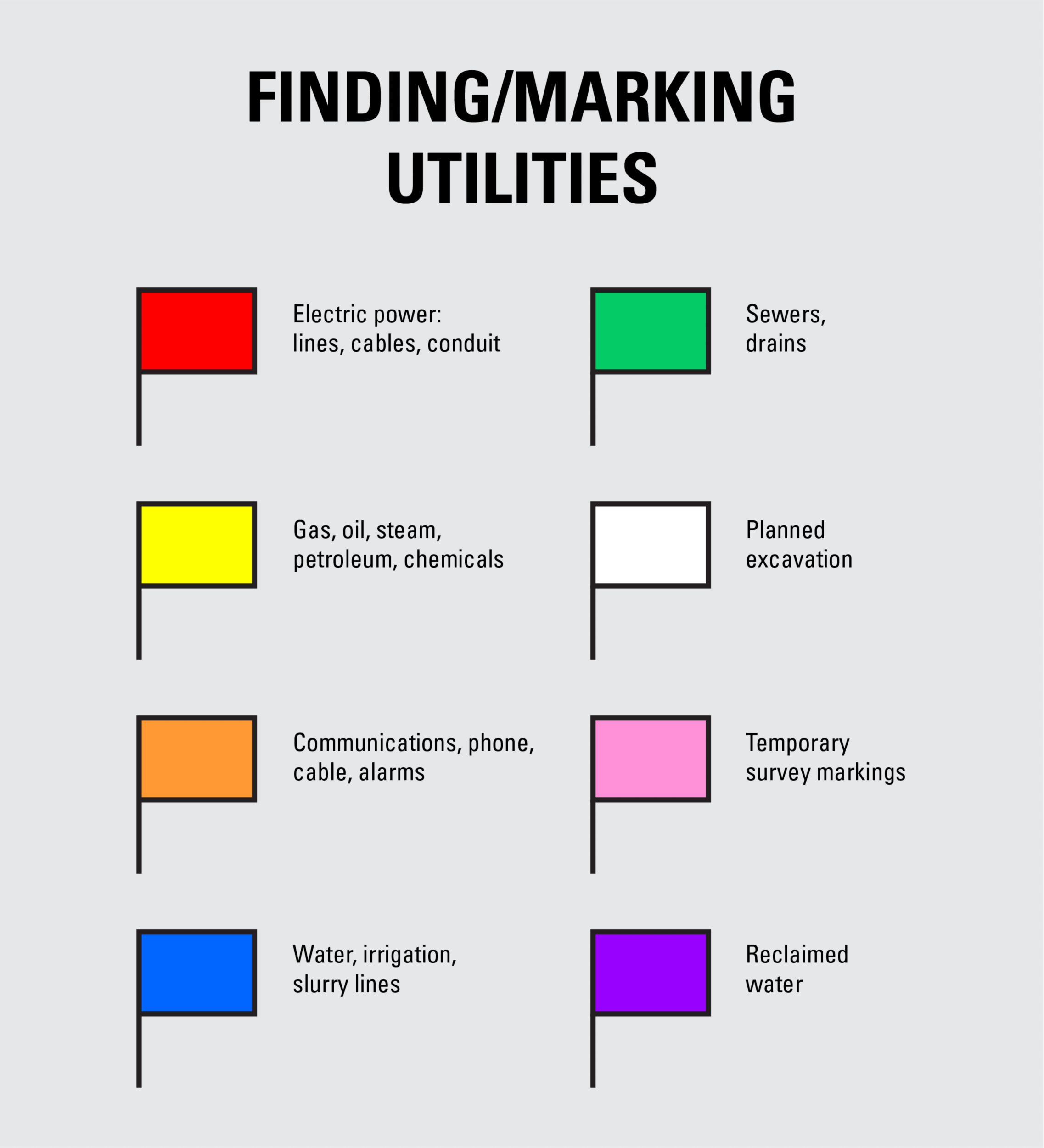

FINDING AND MARKING UTILITIES

It is extremely important that you call the local One Call System in your region before you begin digging. This is required by law and will save you the hassle and massive fines of damaging underground utilities. Make a call at least 48 hours before you plan to start digging and identify the time and place of your excavation. Your information will be logged, and local utilities will be alerted to come to your dig site and mark their facilities.

Markings are approximate and there is a tolerance zone between 18 and 36 inches to either side of the mark. Don’t dig inside the tolerance zone and risk rupturing utilities.

Markings are made by flags that are color coded based on which utility is buried on your site:

- Red flag: Electrical power lines, cables, conduit or lighting cables.

- Yellow flag: Natural gas, oil, steam, petroleum, chemicals or other gas.

- Orange flag: Communications, phone lines, alarm lines, signal lines or cable TV.

- Blue flag: Water, irrigation or slurry lines.

- Green flag: Sewers or drains.

- White flag: Planned excavation.

- Pink flag: Temporary survey markings.

- Purple flag: Reclaimed water.

Never assume someone else has made the call to the One Call System. Remember: It’s better to call twice on the same job than to arrive for work and find that nothing has been marked.

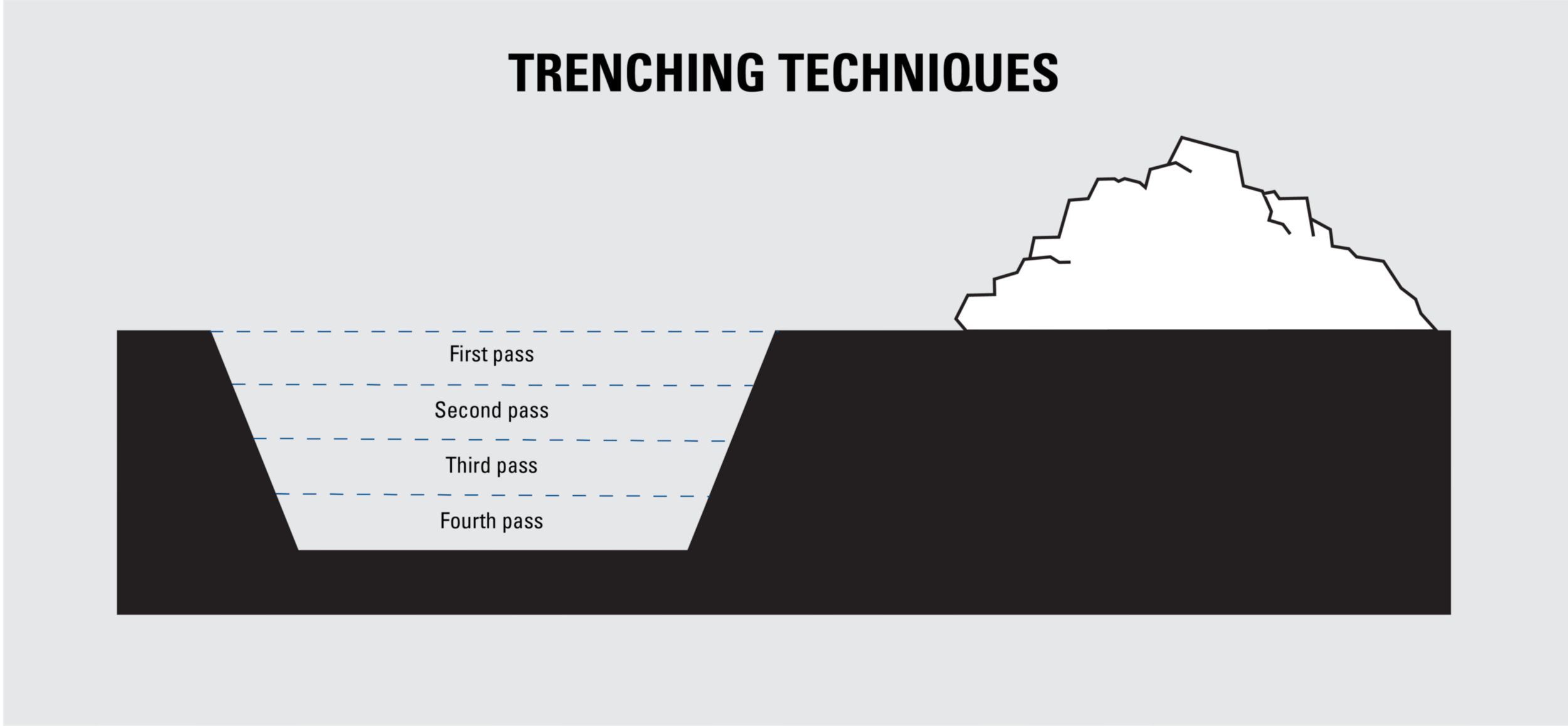

TRENCHING TECHNIQUES

When trenching, start at the top and work down in layers. Don’t dig from the bottom and fill your bucket by raking up the face. Digging from the bottom up is much harder and extends your cycle, because you’ll be going all the way to the bottom of the trench on each pass.

Set your excavator facing the work area. Avoid digging over the side.

Every excavator has a maximum digging envelope. Within that is a working range that is the most efficient. Work in this range to maximize your digging forces and use the force of the stick and bucket to get full bucket loads with every pass.

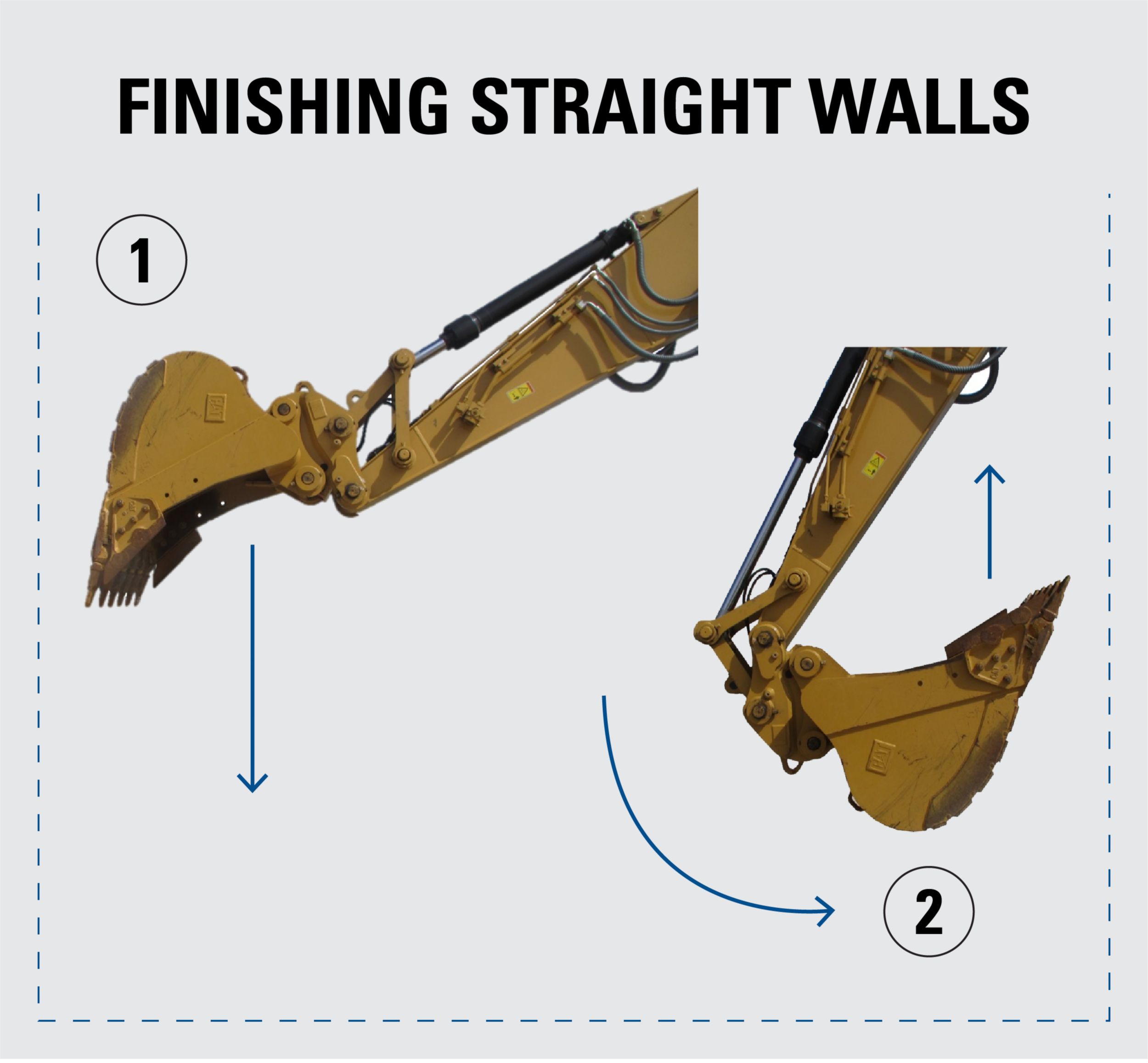

To finish the straight walls of your trench, finish the far wall first. To move your bucket in a straight line, move the stick out while you move the bucket down. Hold the bucket open and vertical. Then move to the closest wall. Lift the bucket upward and keep the cutting edge vertical.

Need additional tips for digging and trenching with your hydraulic excavator? Caterpillar offers extensive operator training through Equipment Training Solutions. Learn more here.

Popular Articles About Excavators

Get the most from your excavators with operating tips, safety advice, maintenance help and much more.

-

The "Value" in a Customer Value Agreement

Check out these 4 ways a Customer Value Agreement helps your equipment and your business.

Read Article -

Mobile Goes Mainstream

Cat mobile apps make it easy to track equipment location, use, health and more.

Read Article -

Your Equipment Is a Reflection of Your Brand

Keep your equipment in good running condition to maximize uptime and reduce operating costs.

Read Article -

Eight Ways to Attract and Keep Top Talent

Hiring and retaining workers can be a challenge. Use these tips find the people you need.

Read Article