Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

TIPS FOR TRUCK LOADING FROM A BENCH

Different worksite scenarios require different truck loading strategies for your hydraulic excavator. Knowing the best practices for truck loading can reduce your excavator cycles, save on fuel costs and keep your worksite moving efficiently. Here are some tips for truck loading while benching that can cut back on time and money.

BENCH LOADING

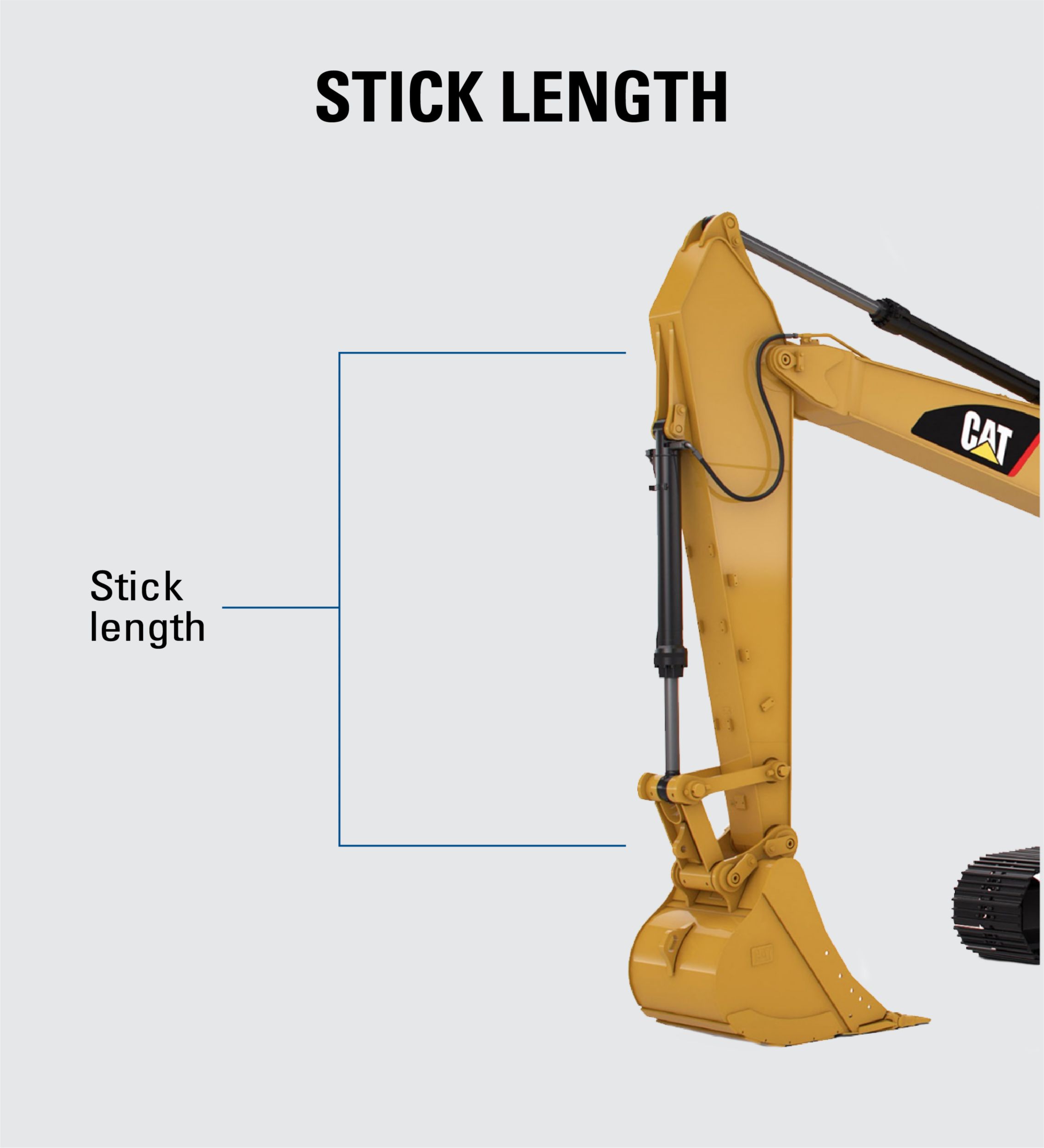

The ideal bench height should be about the length of your excavator’s stick, from boom pin to stick pin. If you are loading unstable material, the height should be a bit lower.

Minimize your cycle times and make your swing distance as short as possible. For most applications, using Smart Mode gives you the right balance of economy and power.

Just as you would when trenching, dig from the top down and work your way across in layers. Going to the bottom of the pile each time takes longer and wastes movement.

The truck should be positioned so the nearest side rail is below the boom/stick hinge. Work as smoothly as possible to avoid spilling material, and dump with the wind at your back to prevent dust from obscuring your vision.

A few extra tips:

- Do not load across the top of the truck cab; as often as possible, load across the left side or rear of the truck.

- Don’t waste movement by raising the boom too high as you swing over the top of the truck bed. Just raise it enough to easily clear the side of the truck.

- Create a full even load across the truck bed as you dump your materials.

- Don’t forget to keep your excavator stabilized and make sure your tracks are facing the area you’re digging.

- Don’t hit your track with your retracted bucket.

OVER-THE-RAIL LOADING

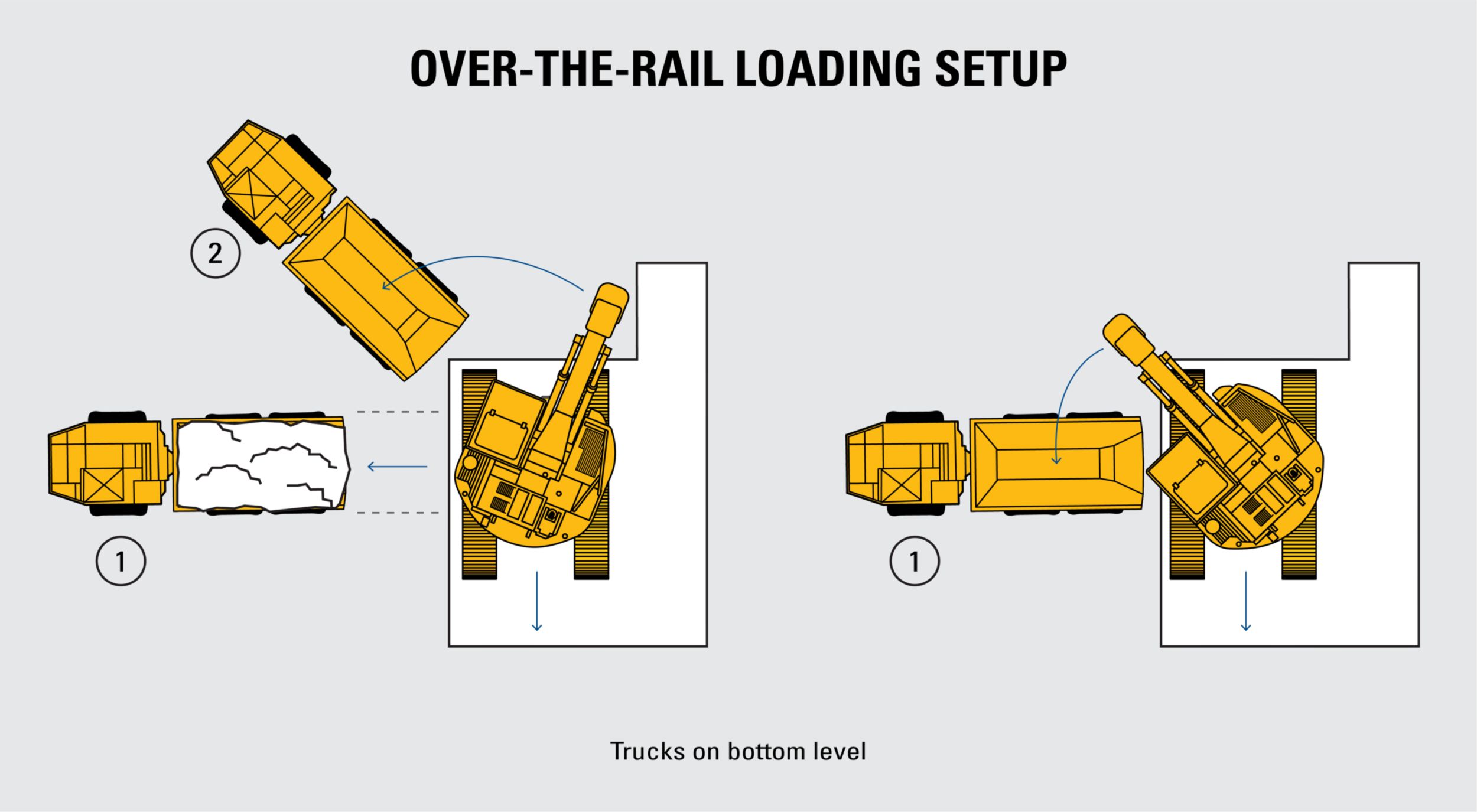

If you’re loading over the rail, the rail should line up with your excavator’s boom and stick pin. Loading over the rail with the truck on the bottom level gives you depth and reach to dig, and allows for alternate truck positions, so you can load one while another truck is getting into position. In this scenario, your swing is minimized — usually 90 degrees for the first truck and only 45 degrees for the second.

THRU-THE-GATE LOADING

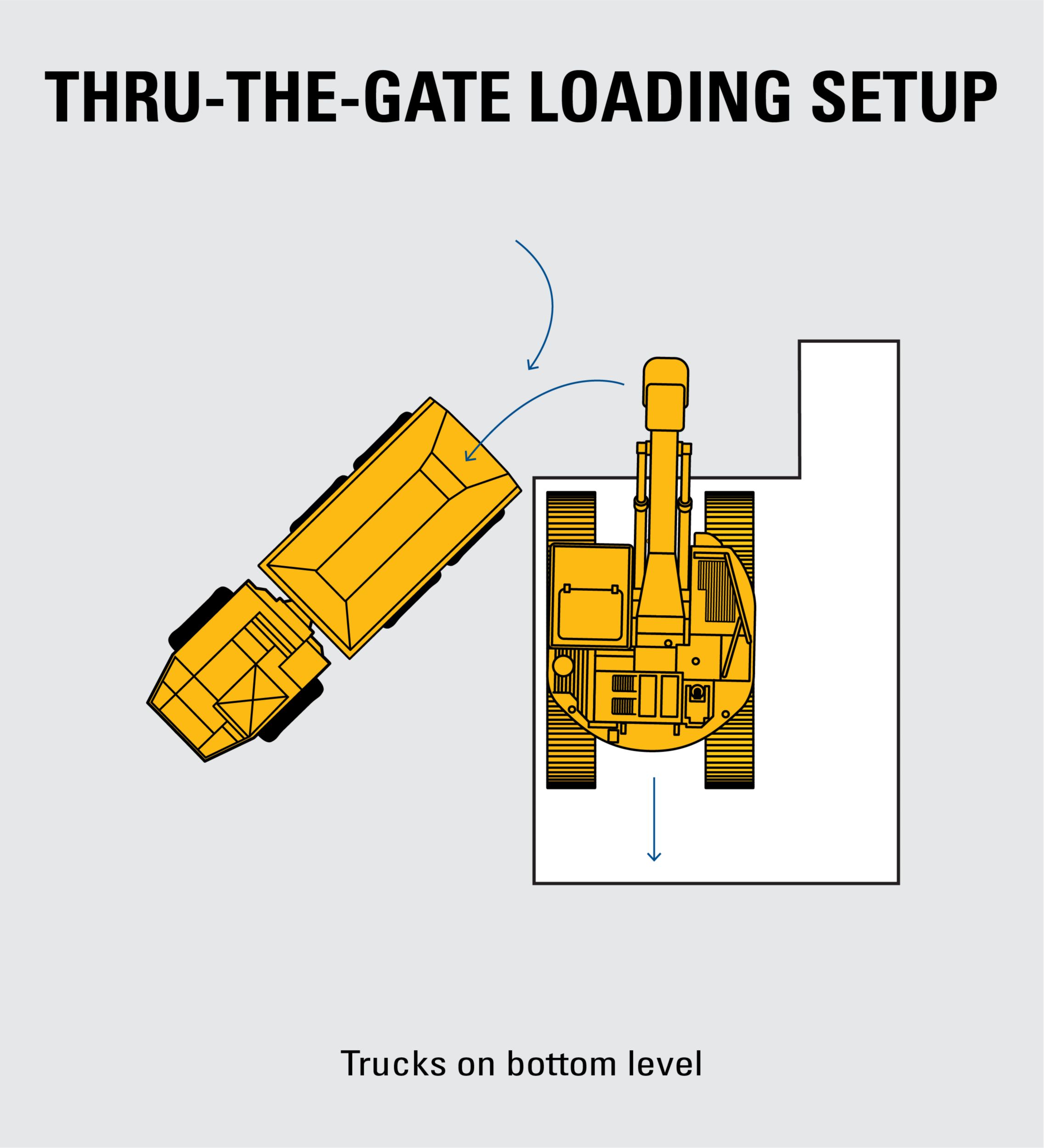

Thru-the-gate loading is a drive-by method best used when the number of available trucks is limited. It minimizes the load time and gets trucks back on the road much more quickly, because trucks don’t need to back into position. Your hydraulic excavator only needs to swing 90 degrees, so cycles move very quickly for the operator.

Make sure to spot the truck with a full bucket, but slightly forward. This positions the truck so you have easy access over the tail. Also, use the swing action to spread material evenly in the truck body. Otherwise you may dump the material, then have to come back and spread it across the truck body, slowing the process down.

BASIC TRUCK LOADING TECHNIQUES

Here are a few basics when loading trucks in any scenario.

- Use your horn to stop the truck when the truck reaches its position. Be prepared to stop the truck if you are loading from the same level.

- Load the truck from the front to the back to help keep the truck balanced. Make sure the load is centered in the truck.

- If you're loading large material, cushion the truck body first by making a pass or two with smaller material.

- Try to set up so you dig on your right and swing to your left to get to the truck. Placing the truck to your left gives you the best view of the truck body.

- Use smooth control movements to save on fuel costs.

- Always spot with a loaded bucket. It saves you half a pass, which adds up over the course of a long workday and saves you fuel.

- Fill your bucket. You'll move more material faster.

- Try to minimize your swing angle to save time and fuel.

- The angle of repose is the angle at which a given material will rest without sliding. Keeping slopes below this angle will minimize slides.

- Make sure to demonstrate and follow safe operating procedures. Do a pre-check of the area to make sure all personnel are clear before beginning to dig.

- When benching, make sure the bench is at a proper height and width. The bed rail height should be the length of your stick. Make sure the bench is wide enough for safe machine operation.

- Your machine should be stable. Position your excavator at a slight angle to the slope in case of slope failure.

- Keep the floor surface level and free of debris. When necessary, make sure the floor surface has proper drainage.

More questions about the best techniques for digging and loading with your hydraulic excavator? Sign up for Cat Equipment Training Solutions’ operator training here.

Popular Articles About Excavators

Get the most from your excavator with operating tips, safety advice, maintenance help and much more.

-

The "Value" in a Customer Value Agreement

Check out these 4 ways a Customer Value Agreement helps your equipment and your business.

Read Article -

Mobile Goes Mainstream

Cat mobile apps make it easy to track equipment location, use, health and more.

Read Article -

Your Equipment Is a Reflection of Your Brand

Keep your equipment in good running condition to maximize uptime and reduce operating costs.

Read Article -

Eight Ways to Attract and Keep Top Talent

Hiring and retaining workers can be a challenge. Use these tips find the people you need.

Read Article