Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

HOW TO SPEND LESS ON PARTS AND CONSUMABLES

CUT COSTS AND DOWNTIME OVER THE LIFE OF YOUR EQUIPMENT

Buying a single filter or replacing an individual part won’t break the bank, but over the life of your equipment the price of consumables can really add up. Even the downtime associated with preventive maintenance and simple repairs can eat into your profits. That’s why we’re always working to extend maintenance and overhaul intervals and component life on Cat® equipment. Here are three simple things you can do reduce operating costs and downtime, too.

1. Repair before failure. Did you know waiting to repair until your engine, transmission or pump fails can cost you 2.5 times more than taking action before failure? Downtime is typically greater, too, since after-failure repairs are more complex. That’s because a catastrophic failure causes contingent damage, requiring you to scrap many parts that otherwise would have been reusable or rebuildable. Using condition monitoring and predictive indicators generated through equipment data helps you forecast when components will fail, so you can plan for service BEFORE that happens — and spend less time and money on repairs.

2. Extend intervals when data supports it. Here’s something else condition monitoring can do for you — indicate if you’re replacing oil and filters too soon or taking equipment off the job for overhauls too early. All manufacturers publish recommended maintenance and overhaul intervals for equipment, but no two operations run that equipment in the exact same way. Based on your site conditions, fuel quality and other factors, the data may show you can push out intervals — and again, that means less wasted time, money and materials.

3. Choose Cat® Reman products when available. When it is time to replace a component, selecting a Cat Reman option gives you same-as-when-new quality and durability, along with a like-new warranty, but at a fraction of the price — generally 50-65% of the cost of a new part. (It’s also a more sustainable choice, reducing water use by 86%, new material use by 85% and greenhouse gas emissions by 61% on average.) There are about 8,000 different types of Cat Reman products available across industries, and we’re actively working to add more to the oil and gas line-up.

Not sure where to start? Try a CVA.

A Customer Value Agreement, or CVA, is an easy way to put these cost-reduction strategies into action. CVAs let you choose a combination of hassle-free maintenance, equipment health data, expert dealer support and other services to maximize your investment and lower your costs. Your Cat dealer can help you put together a CVA that lowers operating costs and downtime.

THE DOWNTIME ASSOCIATED WITH PREVENTIVE MAINTENANCE AND SIMPLE REPAIRS CAN EAT INTO YOUR PROFITS. THAT’S WHY WE’RE ALWAYS WORKING TO EXTEND MAINTENANCE AND OVERHAUL INTERVALS AND COMPONENT LIFE ON CAT® EQUIPMENT.

Related Stories

-

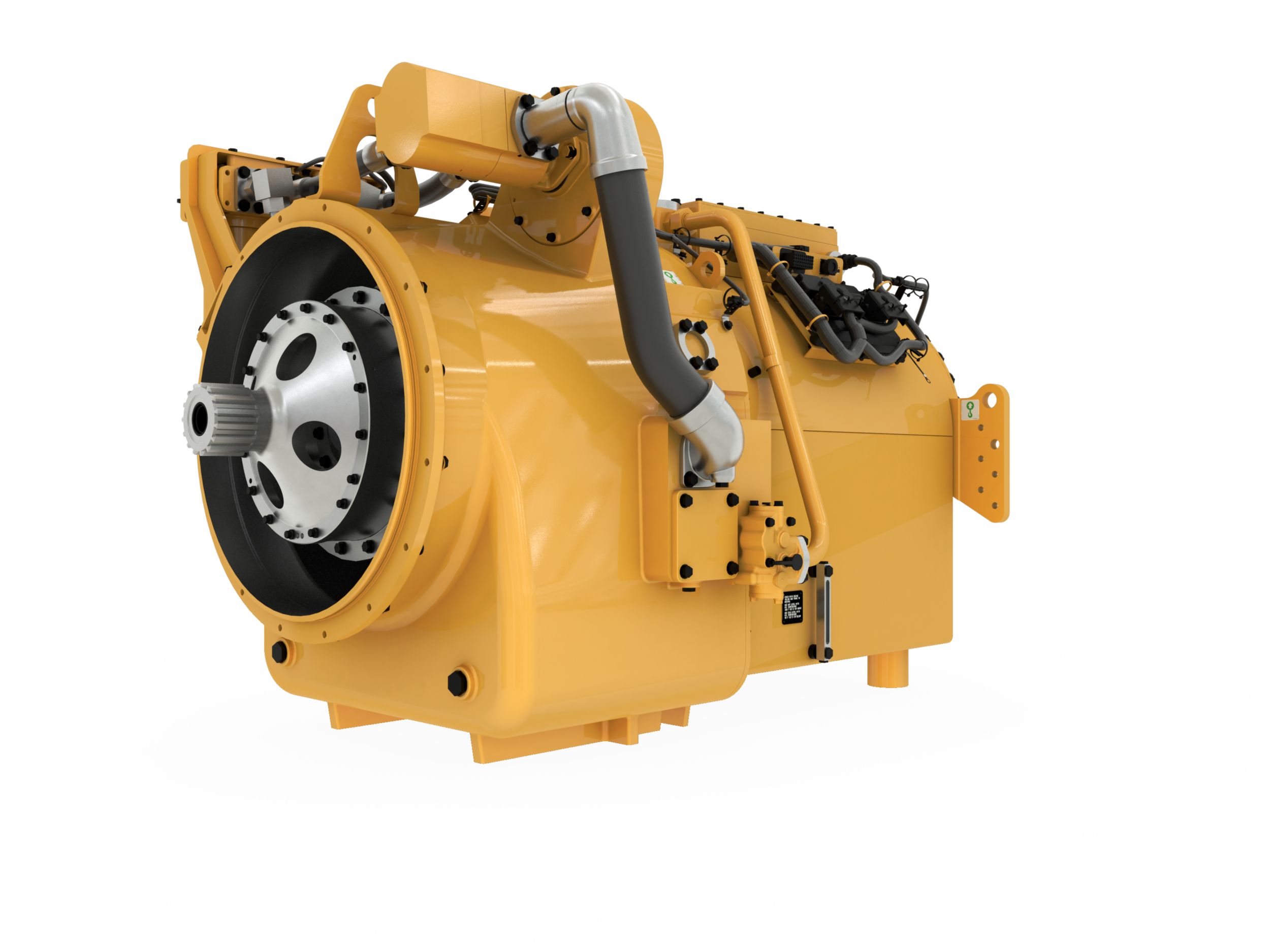

Caterpillar Announces TH55 E70 & E90 Reman Transmissions for Oil & Gas

Caterpillar Oil & Gas introduces the Cat® TH55 E70 and TH55 E90 Reman transmissions for use in oil & gas pressure pumping applications.

Learn More -

Health & Operations Monitoring, Enabled by Cat® Remote Fleet Vision

In just a few clicks Cat® Remote Fleet Vision allows you to locate, track and manage all your assets and receive customized data.

Learn More -

Turbocharger for Gas Compression Engines

The new Cat® Turbocharger offers proven reliability and durability with lower repair costs, less downtime and longer service intervals.

Learn More