Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

A Layered Approach to Fatigue and Distraction Management

See how two mines owned by PanAust Limited have approached fatigue and distraction management.

By Caterpillar | Posted December 21, 2022

Safety is a priority for every mining operation today, and it’s an ongoing challenge as miners continually seek new ways to keep people safe. Even large mining companies with strong practices and processes can have a difficult time achieving safety goals.

Operating a mine in a developing country introduces additional challenges. These countries sometimes lack well-established regulations, and the workforce is often made up of inexperienced, first-generation mining employees who unlike their counterparts in developed mining regions are unaware of potential safety issues — as well as the steps that can be taken to mitigate them.

But that’s not to say that significant progress can’t be made. Take the two mines owned by PanAust Limited in the Lao People’s Democratic Republic (Laos), for example. These mining operations have gone on a significant journey to improve their safety standards and practices since operations began.

Some of the most significant safety issues on the mine were due to operator fatigue and distraction. After several years of poor performance, PanAust began a journey that progressed from education and a fatigue management plan to implementing one of the most sophisticated detection technologies in the market — the Cat® MineStar™ Detect Driver Safety System (DSS).

“At PanAust, our commitment to safety is underpinned by our Zero Harm philosophy whereby all incidents are considered preventable,” says David Reid, General Manager Operations. “The Driver Safety System supports our commitment to keeping people across our operations safe.”

ABOUT PANAUST

PanAust’s operations in Laos are operated by Phu Bia Mining Limited (PBM), which is 90% owned by PanAust and 10% by the Government of Laos. PBM operates two mines within PanAust's Phu Bia Mining Contract Area in Laos, approximately 190 kilometers (87 miles) north of Laos' capital city, Vientiane.

Phu Kham Copper-Gold Operation is PanAust’s flagship operation. Phu Kham comprises an open-pit mine feeding ore to a process plant with the recovery of copper and precious metals into a saleable concentrate using conventional flotation technology. In 2019, ex-pit material mined at Phu Kham totaled 47 million tonnes (52 million tons) and included 16 million tonnes (18 million tons) of ore. The process plant milled over 18 million tonnes (20 million tons) of ore.

Phu Kham trucks approximately 80% of its concentrate in covered containers to the ports of Vung Ang or Hon La in Vietnam (each about 650 kilometers/404 miles from Phu Kham). The remaining 20% is trucked to the Sriracha Harbour in southern Thailand, approximately 1,000 kilometers (404 miles) from Phu Kham, for export to smelters mainly in Asia.

About 25 kilometers (15.5 miles) west of Phu Kham is the Ban Houayxai Gold-Silver Operation. Commencing production in 2012, the operation comprises an open-pit mine feeding ore to a conventional carbon-in-leach recovery process plant. In 2019, the operation produced 103,289 ounces of gold and 730,344 ounces of silver in doré.

Machines and support

The loading and hauling operations at Phu Kham and Ban Houayxai consist of face shovels and excavators loading Cat 777D 90-tonne (100-ton) trucks — 53 at Phu Kham and 11 at Ban Houayxai. Ancillary equipment includes Cat D10T dozers, Cat 16M Motor Graders and Cat 990 and 992G Wheel Loaders.

The mines do the majority of their own equipment maintenance, with each operating a component rebuild facility. Their mobile maintenance workshops and associated supply facilities have consistently achieved the Caterpillar 5-Star Contamination Control rating, which demonstrates a commitment to clean facilities, components, processes and fluids.

PBM also relies on support from Cat dealer Metro Machinery Company Limited (MMC). The authorized Cat equipment dealer in Thailand since 1977, Metro Machinery supports PBM operations through its subsidiary Lau Metro.

MINING IN A DEVELOPING COUNTRY

A landlocked country in Southeast Asia, Laos is a developing nation that is heavily reliant on subsistence farming and other small-scale industries such as wood processing, tourism and artisanal mining. The country has two primary natural resource industries: base and precious metals mining and hydroelectric power generation.

The introduction of modern mining operations like Phu Kham and Ban Houayxai uncovered the need to build workforce capability and develop employees through training and the implementation of management standards. To address this need, and to ensure the company leaves a lasting positive legacy in Laos, PanAust developed and implemented a Trades Training Program, which encompasses an apprenticeship program that builds a pool of talent for the company’s operations.

The Lao people have been eager to learn and quick to develop the necessary skills; however, addressing cultural differences has proven to be a challenge for PanAust.

One of the most significant challenges was delivering a coherent and meaningful safety message to the Lao national workforce. “It was critical that our Lao employees understood the importance of safe operations and accepted responsibility for individual behaviors,” says Wen fu Wang, Managing Director of Phu Bia Mining. “The safety message had not penetrated the lexicon and had little meaning to the local population. They seemed unaware of the potential long-term benefits that could be gained via compliance with our safety requirements.”

Over the next several years, the company recognized that a lack of understanding was standing in the way. So, while employees focused on developing a better understanding of their employer’s requirements, PanAust worked to improve its knowledge of and appreciation for the local culture.

The company also realized that it needed to develop a better understanding of what was causing the problems.

IDENTIFYING THE CAUSES OF SAFETY ISSUES

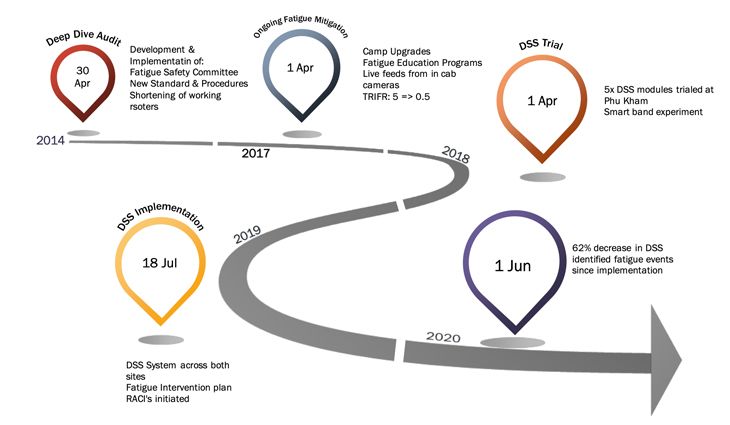

In 2014, the site management teams, together with organizational support from PanAust, developed a plan to improve the safety performance at its mining operations. The company reviewed four years of safety incident data at the onset of the program in 2014.

This initial audit discovered:

- 48 vehicle-to-equipment, or equipment-to-equipment, contact events — an average of 12 incidents every year.

- 38 equipment-to-environment or infrastructure contact events — an average of 9.5 events every year.

These 86 events formed the basis for statistical evaluation and were further analyzed to determine the primary causes. They found:

- 16 of the 86 events were due to poor communication practices.

- 26 of the 86 events were directly attributable to fatigue.

- The remaining 44 events were directly attributable to the procedural and behavioral nonconformance, including 10 events linked to the use of mobile phones while operating machinery.

The data uncovered that 30% of the events in those four years happened because operators were fatigued, and site teams suspected that number could be even higher. The company also found that another 12% of these events were linked to distraction — in this case the use of mobile phones. These problems combined for nearly half of the incidents that occurred in those four years.

At that time, a basic paper-based fatigue management system was in place for equipment operators. In addition, operators had been trained and competency records were being kept. The evidence, however, indicated that complacency had set in. Training records were incomplete and trainers had different opinions about what was required. The basic systems were fragmented and didn’t communicate with each other. The company had procedures in place, but there were different versions available, and, in some cases, employees weren’t even aware the processes existed.

The company knew that this was a big issue, but it was also clear that it could do something to address it.

ADDRESSING FATIGUE AND DISTRACTION

About 5 years ago, PanAust formed a fatigue committee comprised of executives and senior managers from across the business. The committee’s mandate is to ensure that any investigation learnings, research or recommendations concerning fatigue management are shared and implemented group-wide.

The committee implemented several initiatives:

- Identification of locations where the concentrate truck drivers could have frequent and timely rest breaks.

- Improvements to operator accommodations focused on noise and light reduction strategies, as well as a reduction in headcount per room.

- A Logistics Safety Day with the theme “Don’t drive tired,” encouraging operators and their families to tour the company facilities, to be aware of the dangers of fatigue, and to inform family members as to how they can support operators to combat fatigue.

- An extension of the highly successful Phu Kham FM radio station to also cover Ban Houayxai.

- The addition of a fatigue management function within the mining fleet dispatching system to prompt drivers to assess their levels of fatigue and to confidentially notify the control room if they are feeling fatigued.

- The assignment of room controllers to the Phu Kham mining fleet accommodation areas to manage and minimize disruptions to personnel when they are sleeping.

- A revision of the fatigue management plan.

- Roster changes designed to shorten the number of consecutive shifts worked before a 24-hour break, as well as the introduction of 15-minute fatigue breaks every two hours during night shifts.

A fatigue management consultant was engaged to review and assess potential risk factors that could arise from the roster arrangements and driving practices on the company’s concentrate haul route from Phu Kham to Vietnam. The review included inspections of the route, company-provided accommodation facilities, driver-reviver stops, and a practical assessment of all procedures for managing fatigue.

During the examination of the existing systems, it became apparent that operators failed to understand how their behavior had directly contributed to safety incidents. Even when investigations showed that an operator was at fault due to fatigue or distraction, the operator was not willing to admit to it. This issue came back to culture.

The immediate challenge was to get the workforce to understand that compliance to safety should be of equal concern as retaining employment, ensuring that crews understood their duty of care requirements and would be responsible for championing and owning their workplace safety.

The next step in the safety journey was the introduction of onboard cameras that monitored operators in the cab and provided a live feed to a team responsible for monitoring behaviors and looking for signs of fatigue.

With these and the other initiatives in place, PanAust saw a significant improvement in safety statistics. By December 2016, the total recordable injury frequency rate (TRIFR) at Phu Kham had decreased from 5 to 0.5, including 10 months at 0 level. The first aid injury frequency rate dropped from 25 to 4, and total potential lost-time injuries had decreased from 43 to 7 events.

The data showed that progress was being made, but site teams knew more could be done. While the in-place initiatives delivered some improvement, a person in the mine control room was still required to watch the screens and try to detect signs of fatigue.

FINDING A SOLUTION

In the fall of 2016, mine managers from Phu Kham and Ban Houayxai observed a new tool — the Cat Driver Safety System — when they visited the Caterpillar booth at MINExpo International® in Las Vegas, Nevada, USA.

A Caterpillar fatigue and distraction expert introduced them to the Cat MineStar Detect safety portfolio, and a dialogue began. What they discovered was a way to identify fatigue and distraction — and address it — in real-time.

Key to the solution is the Cat DSS, a non-intrusive, in-cab fatigue detection technology that instantly alerts operators the moment fatigue or distraction is identified. It works by monitoring eye-closure duration and head pose. If the system detects a fatigue or distraction event, the operator is immediately alerted through an in-vehicle seat vibration and/or audio alarm.

The system goes beyond identifying a single incident to providing customized data and reporting for continuous improvement and safety education site-wide. The DSS feeds data to the Cat Fleet Monitoring Center, where safety advisors work around the clock to analyze data and video from the system and notify on-site personnel about drowsy or distracted driving.

What this system offered PanAust’s mines was the ability to immediately notify an operator if they were driving while distracted or drowsy. The system does that by itself, without any input from the operator or someone watching a screen. It also links education with action to encourage fatigue awareness and a change in behavior.

For example, when the DSS detects a second microsleep, the operator is immediately removed from the truck and a fatigue assessment is conducted. During this assessment, the operator has the opportunity to understand the contributors and proxies to fatigue, such as hours of sleep, medication, yawning, dehydration and head nodding.

As operators have become more informed on how the onset of fatigue may affect them, Phu Kham has seen a major behavioral shift. Operators are now volunteering to be relieved of driving duties for an assessment after being detected for a first microsleep event. This is an essential step in overcoming the stigma of being seen as weak if they are unable to continue working due to fatigue.

After the mine managers returned to Laos, safety initiatives continued to be refined and improved on both sites. While some progress had been made, fatigue and distraction continued to be an issue and the fatigue committee continued to search for additional solutions.

In 2017, the committee began to evaluate fatigue management technologies and circadian rhythm monitoring watches for personnel. In 2018, PBM mining installed the DSS on five haul trucks at the Phu Kham operation and implemented a trial of the Cat Smartband, a wearable technology that identifies quality and quantity of sleep as well as the prime time for fatigue.

They also partnered with Caterpillar on a Fatigue Risk Assessment, which used data from the DSS and the Smartband to provide real information that would reveal the scale of the problem.

After seeing the results of the trials at Phu Kham, the company made the decision to move forward with DSS system across the entire truck fleet at both operations In 2019, PBM approved the purchase of the DSS, with equipment delivered to the site in July and implementation completed just 66 days later.

IMPLEMENTING THE TRIAL

The DSS identifies and reports on three areas of interest:

- Fatigue — the length of time that eyes are closed.

- Distraction — the length of time the operator looks away from the road.

- Field of View Exception (FOV) — the length of time that the sensor cannot detect a face.

The trial was completed in three phases. Phase 1 determined the baseline, with the DSS installed and collecting data, but the in-cab alarms were turned off. In Phase 2, alarms were turned on to notify operators of fatigue and distraction events. Phase 3 added live monitoring of the DSS data.

The table below shows assessment data for all three phases.

PHASE 1: SILENT |

|||

Phu Kham |

BAN HOUAYXAI |

||

Distraction events |

2,833 |

Distraction events |

1,260 |

Fatigue events |

5,117 |

Fatigue events |

767 |

PHASE 2: ALARMS |

|||

Phu Kham |

BAN HOUAYXAI |

||

Distraction events |

1,151 |

Distraction events |

204 |

Fatigue events |

315 |

Fatigue events |

27 |

PHASE 3: LIVE MONITORING |

|||

Phu Kham |

BAN HOUAYXAI |

||

Distraction events |

3,723 |

Distraction events |

1,428 |

Fatigue events |

224 |

Fatigue events |

59 |

While the assessment was initiated to test the DSS, the mines saw significant reductions in fatigue during the trial itself — reducing it by 99% at Phu Kham and by 95% at Ban Houayxai.

The company said the DSS implementation was managed well — from identification of the system to communication and sourcing, through the follow-up — which played a big part in its success across the two sites.

Despite early project challenges caused mainly by parts supply constraints, these problems were overcome collaboratively by PBM, Caterpillar and Metro Machinery. The project was successfully delivered ahead of schedule, on budget and with world-leading results.

GETTING OPERATORS ON BOARD

Change management is required every time a new technology or process is implemented into an operation. Fortunately for PanAust, operators at Phu Kham and Ban Houayxai were already accustomed to having cameras in the fleet cabs. But there was still work to be done to get them comfortable with the DSS — ensuring workers understood what would be happening both inside the cab and at the fleet monitoring center.

Unlike the previous in-cab system, the DSS doesn’t deliver a live feed that requires someone to be watching the operators at all times. The DSS is not closed-circuit television, and someone is alerted only if there is a fatigue or distraction event detected.

When an event such as a microsleep is triggered, the two in-cab alarms are activited: an audible alert of a spoken voice advising that a microsleep has been detected, plus a vibration motor that gently shakes the seat. A third alarm is registered with the fleet monitoring team, who then make radio contact with the operator.

The Caterpillar and PBM teams worked together to make the implementation as easy as possible for operators. “We actually translated the presentations that we would do for the operators so they could follow along in their own language,” recalls Matt Sampson, regional representative, Caterpillar mining technologies. “We also made up a kit that we put in the crib room so they could have a look at the DSS and see how it works and how it feels. We wanted to familiarize them with what the vibration would feel like, what the voice would sound like, how it was automated and how it worked.”

The implementation team even ensured the voice on the spoken alarm was translated into Lao. When the test unit was set up in the crib hut, it allowed the operators to become familiar with the two in-cab alarms before an actual activation. The in-cab alarms consist of a spoken, audible alarm, which is generally in English; however, it was deemed vital that a Lao-specific audible alarm be recorded to ensure the importance of the message in the alarm was clearly understood. The second alarm is the seat vibration shaker. Both alarms were well received by the operators.

MANAGING THE OUTCOMES

Once the DSS was fully implemented across both sites, the data identified the extent of the fatigue issue across the operator fleet. The focus then became how to change behaviors.

PBM began to see the shift in behavior and improvement in safety statistics it had been seeking when it coupled the DSS with its fatigue management processes.

Understanding the culture continued to be the key to success. In Lao culture, conflict is avoided, as are situations with a potential for them to “lose face.” Although the workforce had developed to be generally compliant and follow the health and safety systems, operators did not feel comfortable admitting they were tired as this would be seen as a sign of weakness. Also, should there be an admission of fatigue, they wrongly assumed that the consequence was a likely conflict issue with the mining operations team.

The DSS helped overcome this cultural barrier by removing the human factor and leaving the determination of fatigue and distraction up to the algorithm. It’s a non-biased view of what has occurred, and because it is immediate, a solution can be applied right away.

A lot of work was done with the dispatch team, developing protocols for how operators would be notified of ongoing fatigue and how they would be removed from operations if necessary.

REAPING THE REWARDS

In the first 6 months after full implementation at Phu Kham, the mine saw a 41% reduction in overall fatigue events and an 80% reduction in truck operators being required to be relieved from driving due to fatigue.

This data indicated that events attributed to fatigue were being reduced, as were the times operators were experiencing fatigue. This points to a successful cultural shift that the site safety team had been seeking.

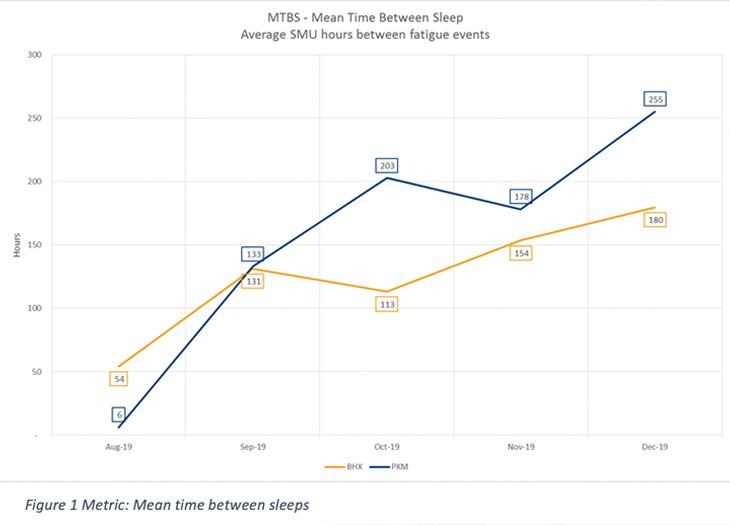

The metric Mean Time Between Sleeps, which measures the average fleet trucks hours against the microsleeps, shows that both sites are continually improving and have not yet plateaued.

PanAust has minimized fatigue and distraction hazards by implementing several overlapping layers for defense, and considers the DSS a pivotal contributor to the company’s overall Fatigue Management System.

In its 2018 Business Review and Sustainability Report, PanAust announced a strong end to the year and outstanding safety performance across the group — a trend it is committed to continuing.

“At PanAust, safety is paramount. Our commitment to our Zero Harm safety objectives not only ensures that our people go home safe every day. It also makes good business sense,” says Dr Qun Yang, PanAust Managing Director and Chief Executive Officer. “As we look to maximize production at our Lao operations to support the growth of the company, safety continues to be our number one priority.”