Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Reman Recycles While Remanufacturing

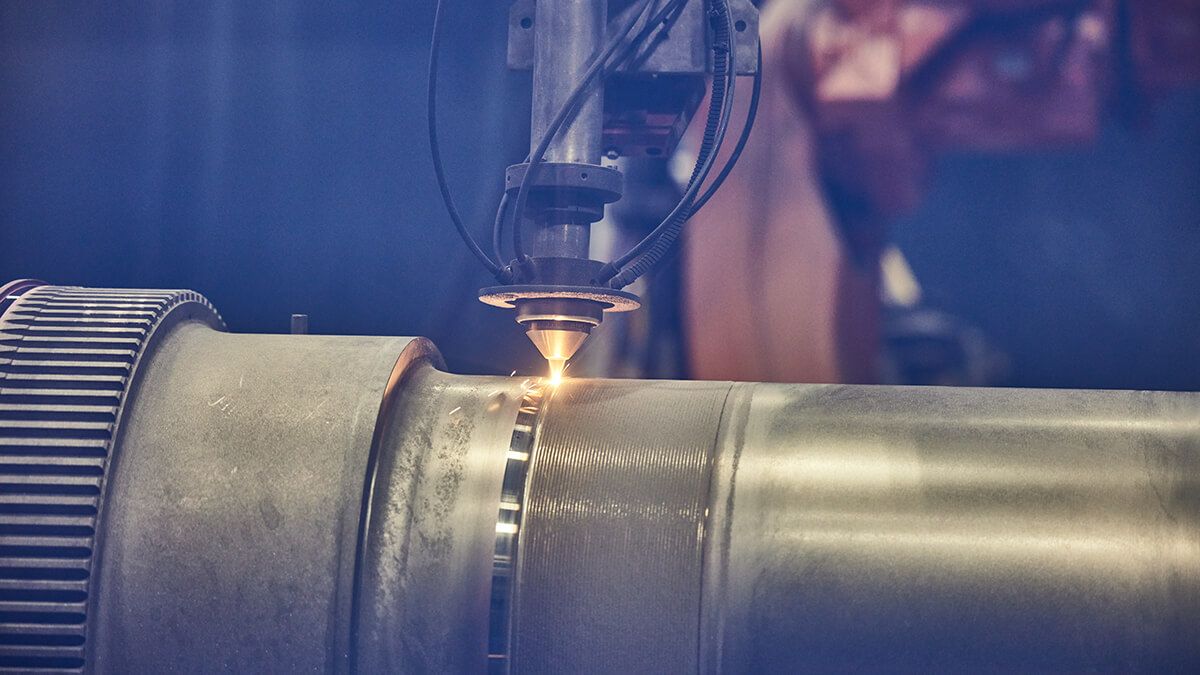

It’s easy to think that Cat® Reman simply remanufactures worn parts to look and perform just like their new counterparts, but it’s about much more than that. During the remanufacturing process, materials and parts that cannot be remanufactured get recycled to be converted back to raw materials.

Estimated read time: 4 minutes

Cat® products are designed to withstand heavy-duty operating conditions and to be restored and used for multiple lifecycles, reducing the need for raw materials and associated greenhouse gas emissions. And that’s where Cat Reman comes in. By making end-of-life parts and components perform like new again, Cat Reman products are part of a circular economy. New parts go out, perform their working life, then come back to be remanufactured and put back into service.

As Cat Reman Engines Product Manager Jeff Gutzwiller explains, Caterpillar Inc. is dedicated to sustainability. Caterpillar engineers design products to last, and, in many cases, to be remanufactured to live multiple lives. “We get the core back from customers through the dealers, we clean it, we salvage it using the state-of-the-art techniques, and then we assemble it in a manufacturing environment to perform like its new counterpart.”

Any manufacturing method produces waste streams. Knowing that, Cat Reman takes steps to manage its own waste streams. For instance, says Reman Engineering Team Lead Kegan Luick, “Many things that are scrapped can be recycled” — even some fluids. Cat Reman also reuses and recycles many fluids (solvents, water, oils) throughout the remanufacturing process.

"When it comes to our recycling program, we're trying to find a home and a second use for everything."

— Perry McClellan, senior Environmental Healthy & Safety associate, North Dakota Cat Reman Facility

Ounce by ounce, pound by pound, recycling various materials and parts quickly adds up. Combined, Cat Reman facilities can average millions of pounds of recyclables per month. “It's very common for the West Fargo plant to recycle half a million pounds of steel and iron each month,” says Perry McClellan, senior Environment Health & Safety (EHS) associate at the Cat Reman facility in North Dakota.

But it isn’t just the valuable scrap metal that gets recycled. “We extend that even further, getting into paper and cardboard products. When it comes to our recycling program, we're trying to find a home and a second use for everything,” McClellan says.

BENEFITS All AROUND

Remanufacturing practices that incorporate sustainability benefits can lead to profitable business opportunities — but not only for Caterpillar. Cat dealers and customers can experience the benefits, too. That’s because Cat Reman parts deliver like new performance for a fraction of the cost of new parts with core return.

Jeff Gutzwiller notes, “We've been in the remanufacturing business almost 50 years, and that's very important to us

because: A) It has sustainability benefits; and B) It's good for our business and our customers.”

Cat Reman General Manager Billy Frank agrees. “There's less energy needed to remanufacture that product as compared to new. So it's good for the customer's wallet, and it helps them make a better, more sustainable world.”

SUSTAINABILITY FROM THE TOP DOWN

The commitment to sustainability and recycling permeates the entire Caterpillar enterprise. “Cat Reman and our products allow for us to deliver solutions to customers while also providing sustainability benefits,” says Remanufacturing Division Senior Vice President Brian Edwards.

And Cat dealers are essential partners for Cat Reman. Returning a core to the circular economy begins with the customer

and Cat dealer employees such as Service Technician Jeff Aberle at Butler Machinery, a Cat dealership in Fargo, North Dakota. From there, the core is sent back to Cat Reman so it can be remanufactured and then assembled into a Cat Reman part to be used again for another customer.

Stocking Cat Reman parts is a given for Butler Machinery. They value the price options, plus the level of availability, says Store Manager Bob Vetter. “Not to mention, being able to reuse a core puts less material in the landfill. Cat Reman has been doing upcycling, reusing and recycling long before it was fashionable.”

Check out the range and variety of available Cat Reman parts.