Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Demonstrating the Value of Vibration Monitoring

Learn how Cat® Electric Rope Shovel Vibration Monitoring can be used to catch sudden changes and prevent costly failures

By Caterpillar | Posted October 16, 2024

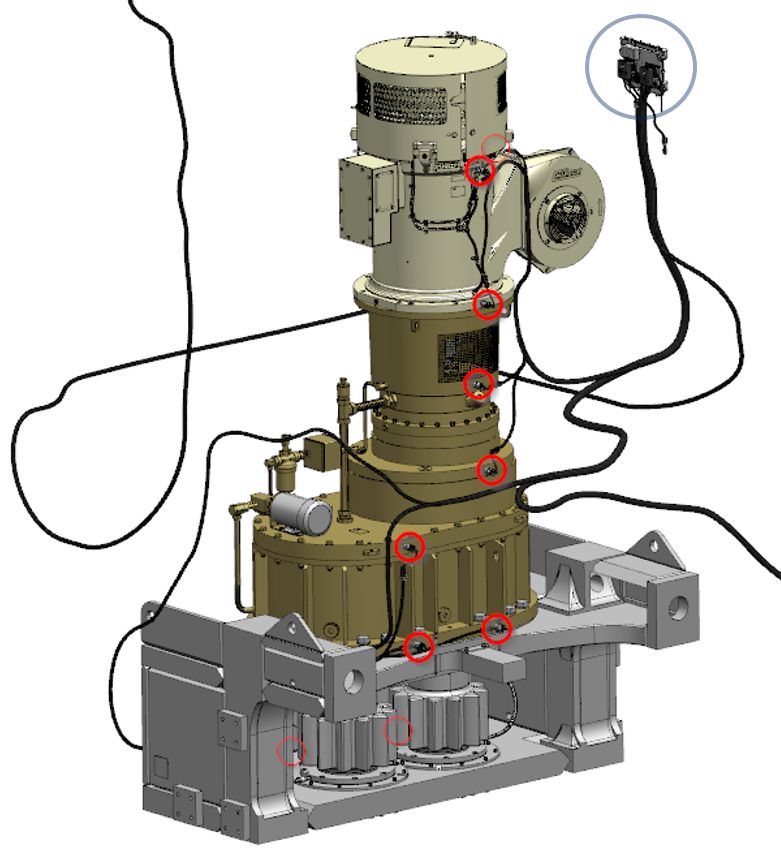

Cat® Electric Rope Shovels can be equipped with a wide variety of optional technologies to track machine health. Normally, these technologies are used to measure and monitor over long periods of time, allowing users to make more proactive maintenance and training decisions — with the ultimate goal of increasing machine uptime and improving operator efficiency.

As part of Cat Electric Rope Shovels Condition Monitoring suite of solutions, Caterpillar experts provide ongoing analysis of vibration data gathered by the Vibration Monitoring System. These drivetrain analysts use the data gathered by the Vibration Monitoring System to track trends and predict when components need to be repaired or replaced to keep the machine running smoothly. Caterpillar is currently running a pilot program with 10 units.

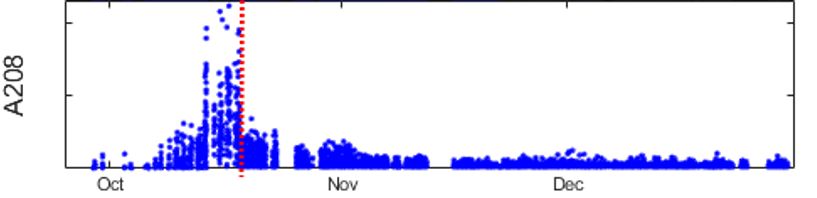

The system takes hundreds of snapshots every day for swing, hoist and rope crowd motions, building a picture for weekly analysis that allows our analysts to provide recommendations and warnings that help customers catch and repair small issues before they develop into costly failures.

One recent event also demonstrated the system’s capacity for rapid capture of events.

One night in October 2023, our drivetrain analysis team noticed an increase in vibration levels in the swing drive system of a customer’s 7495 HR Electric Rope Shovel. This increase was beyond what could be expected from ordinary wear and tear on components during regular operation. The team quickly reached out to the customer to determine the cause and stop a larger problem in its tracks.

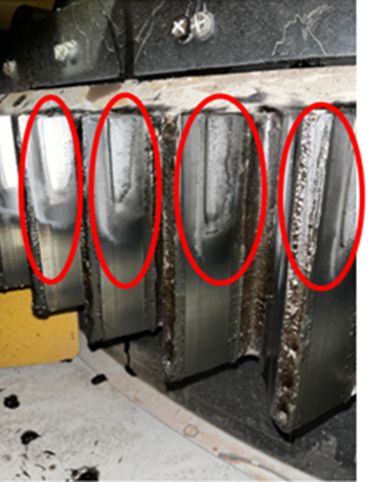

What they heard demonstrated the value of the Vibration Monitoring System. That same night, onsite personnel reported a strange noise during the shovel’s swing cycle. They contacted their Cat dealer to perform an investigation, and the dealer’s personnel found what was making the sound: a lubrication film had been improperly applied to the swing rack, resulting in progressive damage. If left unnoticed, this issue could have led to major failure, unplanned downtime and costly repairs.

“We are very proud of the capabilities of this new technology and its ability to capture developing drivetrain system issues before they can turn into more serious issues,” said Senior Engineer Tim Schultz. “This is a big win for the customer in giving them another tool to prevent unplanned downtime and improve their machine’s total cost of ownership.”

GET THE LATEST FROM CATERPILLAR MINING DELIVERED RIGHT TO YOUR INBOX