Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Using Fleet Management Technology to Pursue Efficiency

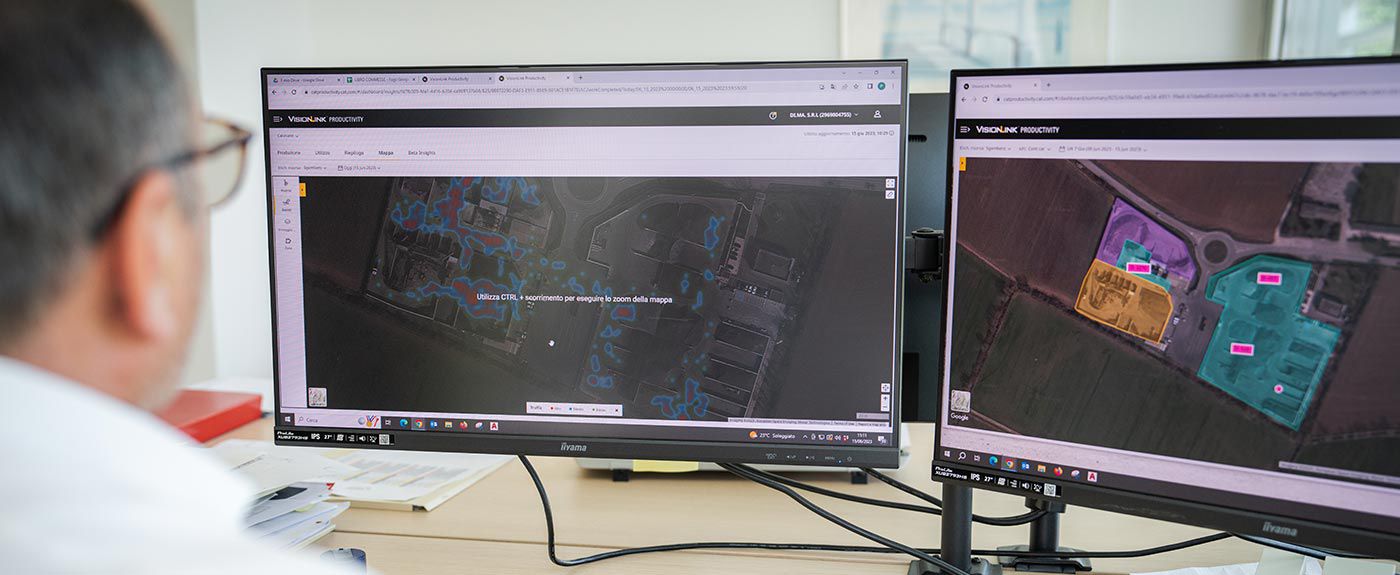

VisionLink Productivity® gives DI.MA an edge in a competitive Italian market

DI.MA is committed to reducing raw material consumption and minimizing recyclable waste in the construction industry. Making the most of resources is a way of life for them.

So, perhaps it was inevitable that they would embrace VisionLink Productivity® to increase the efficiency of their own sites. This easy-to-use cloud-based platform visually represents machine data at jobsites to analyse performance, improve productivity, and, ultimately, increase your profits.

Data accuracy

“In the past, we compiled our data manually and then analysed and reprocessed it, which was slow and not always accurate,” says Gianluca Gamba, DI.MA Technical Director. “But we have been using VisionLink Productivity for three years to monitor a range of information, including load cycles, idle time, and work rates and have seen the benefits. This pushed us to dig even deeper into the data to see what other insights and improvements we could find.”

To help them maximise the benefits of VisionLink Productivity, Italian Cat® dealer CGT put DI.MA in touch with the Caterpillar® Development Team who are always looking to develop the next generation products.

Andrea Bresciani

Condition Monitoring and Digital Application Manager

CGT

VisionLink Productivity brings change

In just three years, mining all this data has brought significant changes for DI.MA. Looking to improve efficiencies they first trialed three different machines: Cat 966M XE, 972M and 972M XE. Then, based on the data they collected from VisionLink Productivity®, they were able to access which machine was most suited for their needs. “We originally had a fleet of Cat 966 wheel loaders, but we discovered that the larger Cat 972 is much more efficient for us and the way we use our machines. They now make up the bulk of our fleet, despite costing more to purchase,” said Paolo Ottonelli, DI.MA President and CEO.

Another change was to redesign the layout of the site itself based on the data collected. This meant enlarging some areas while reducing the size of others, or moving specific areas to be closer together and so reduce machine time between them. Every change has helped make the site more efficient.

Asked what made him most proud of his working relationship with DI.MA, Andrea said, “It’s not just with DI.MA, but all my customers. It’s that moment when they start to trust our data and see that it can make them better at what they do.”

Related Stories

-

Thieves 0 – Caterpillar 1

The fascinating (and true) story of how Visionlink® helped recover a stolen Cat® Backhoe Loader.

Learn More Technology -

Caterpillar and AI: Three Ways Smart Technology Makes Work Easier

Learn how Caterpillar utilizes AI within our technology product offerings, including applications in fleet management, equipment maintenance and parts.

Learn More Technology -

Cat® Onboard Technology

Next Generation Cat® excavators set a new standard for technology in the cab. Learn how Cat Onboard Technology makes it easier, faster and cheaper to do your job.

Read more -

Field Follow Program Gives Customers What They Want

Discover how the Field Follow Program makes our machines better and our customers more loyal.

Read more