Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Transient Performance Specifications for Diesel Generator Sets

ABSTRACT

This paper investigates the specifications that require ISO 8528-5 performance class G3 transient performance for diesel generator sets (or gensets). It will discuss ISO 8528-5 definitions in the context of electric power applications.

Site Requirements and Drivers

Most electric power genset users have transient response requirements. These requirements are defined by the user/consultant based on their specific site loads. Differing loads are precisely why ISO 8528-5 defines multiple performance classes and provides standards for the industry. Many electric power installations will fall into all or part of one of the three defined performance classes. As modern loads such as electronics, UPS, and variable speed drives increase in sensitivity to voltage and/or frequency deviation, more specifications are written around performance class G3.

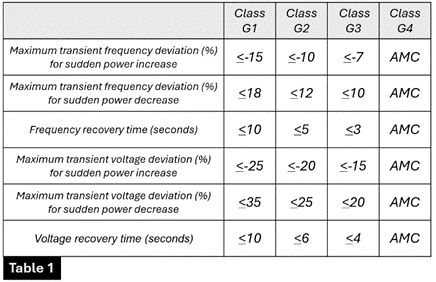

In addition to the three defined performance classes, there is a fourth performance class (G4). This class is reserved for limits that are unique and must be agreed upon by the manufacturer and their customer. See Table 1 below for performance class operating limit values for load increase and decrease as defined by ISO 8528-5.

While specific site load requirements will drive a specific performance class for load acceptance, load rejection limits as defined by ISO 8528-5 are of no or little importance in many circumstances. The transient frequency deviation related to rated frequency for load rejection is defined as a 100% sudden power decrease. In application, this would typically be caused by a breaker open situation. Therefore, the loads would no longer be supported by the generator set at all. For most sites, the need is only that the generator set remains running after the breaker open event and is again ready to accept load.

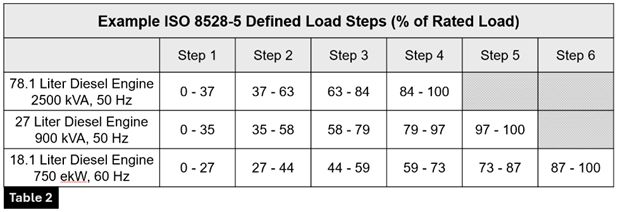

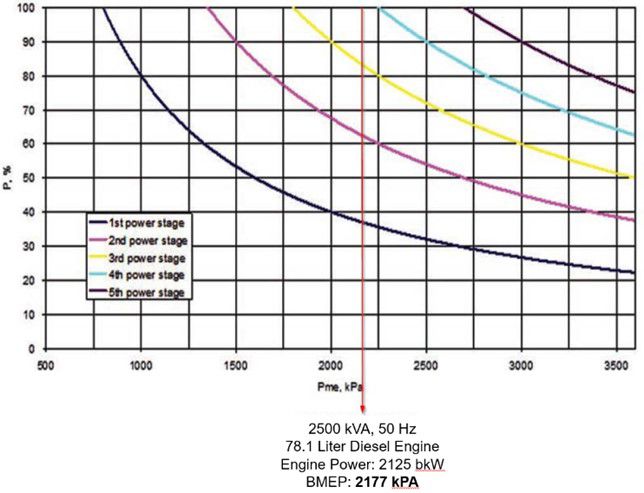

Not only does ISO 8528-5 define operating limits for each performance class, it also defines the magnitude of the load steps for which the performance classes are relevant. The load steps are based on the Brake Mean Effective Pressure (BMEP) of the engine. BMEP is a relative number that is only used as a standard to compare engines of different designs or sizes. Depending on the engine and its rating, the genset will typically reach full load in three to six steps as per the ISO 8528-5 load step definition. All the limit values of a given performance class must be met for each of the load steps in order to be considered as meeting that performance class. An example of ISO8528-5 defined load acceptance steps for a few different gensets can be seen in Table 2 below. See the appendix to determine ISO 8528-5 load steps for any genset powered by a four-stroke engine.

In many cases, there seems to be some confusion in the industry regarding the load steps associated with these ISO 8528-5 performance classes. Many specifications state that they require G2 or G3 performance class, yet they define custom load steps. If any load steps other than the ISO 8528-5 load steps are defined in a specification, performance classes G1, G2, or G3 are not applicable. Performance class G4, which is used for custom performance levels, would need to be utilized in this case.

One recent example of this involved a request for compliance to the G3 performance class for load acceptance and steady state. At face value, this seems like a straightforward request. However, in a different section of the specification, it called for the capability to accept a 0 – 60% load step. Following a request for clarification, it became apparent that G3 performance class was expected for the custom 0 – 60% load step. This is obviously performance class G4 and required agreement between the manufacturer and customer. In most cases, transient performance data is not available for custom load steps for a given genset configuration, meaning only estimates can be provided.

Genset Transient Performance

Although transient response is typically part of the genset development process, the actual performance capability of a given genset may not be well-publicized. This is due to the complexities of quantifying all influences that impact transient response. With the flexibility in genset configurations that can be supplied, there are significant differences in rotational inertia primarily driven by generator arrangement and engine driven equipment such as radiator fans. In general, higher inertia improves the transient response of a given genset.

After an extensive review of one manufacturer’s factory test results, nearly all of their diesel gensets in the 750 – 4000 ekW power range meet performance class G3 for load acceptance regardless of generator size and with or without a mechanically driven radiator. Additionally, these gensets meet G3 performance class for steady state performance. This information is typically found on their genset spec sheets.

Oftentimes these same gensets can be configured to meet performance class G3 for load rejection. This would enable the genset to comply with performance class G3 in its entirety and would be accomplished by oversizing the generator (adding inertia). As discussed earlier in this paper, G3 for load rejection is rarely required. Therefore, adding cost by oversizing the generator to meet G3 for load rejection is not typical.

Appendix

Figure 1 below can be used as a reference to determine ISO 8528-5 defined load steps for four-stroke engines. As is shown in the example, BMEP at 100% load for a given engine can be calculated or provided by the manufacturer. Find that BMEP in kPa on the x-axis. Where a vertical line from that point on the x-axis crosses the power stage curves, defines each load step for that engine. In this case, the load steps would be 0 – 37%, 37 – 63%, 63 – 84%, and 84 – 100% for a 2500 kVA, 50 Hz genset driven by a 78.1 Liter four-stroke engine.

References

International Standard ISO 8528-5:2022