Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

“THE KEY TO OUR SUCCESS IS THE A4 ENGINE”

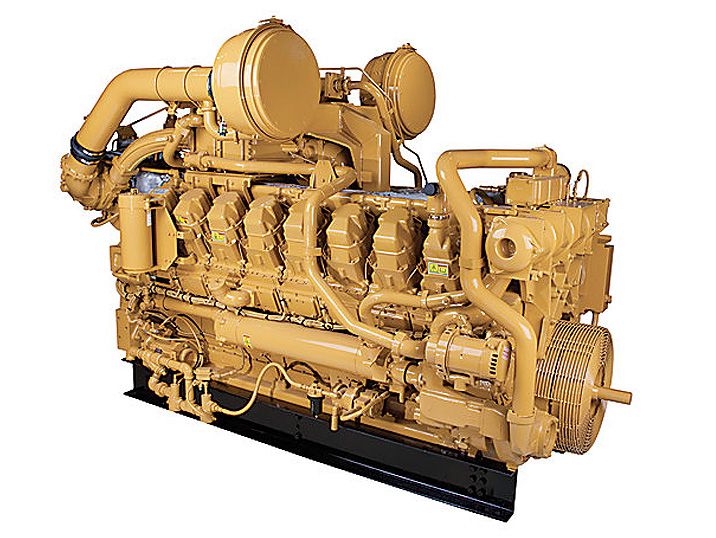

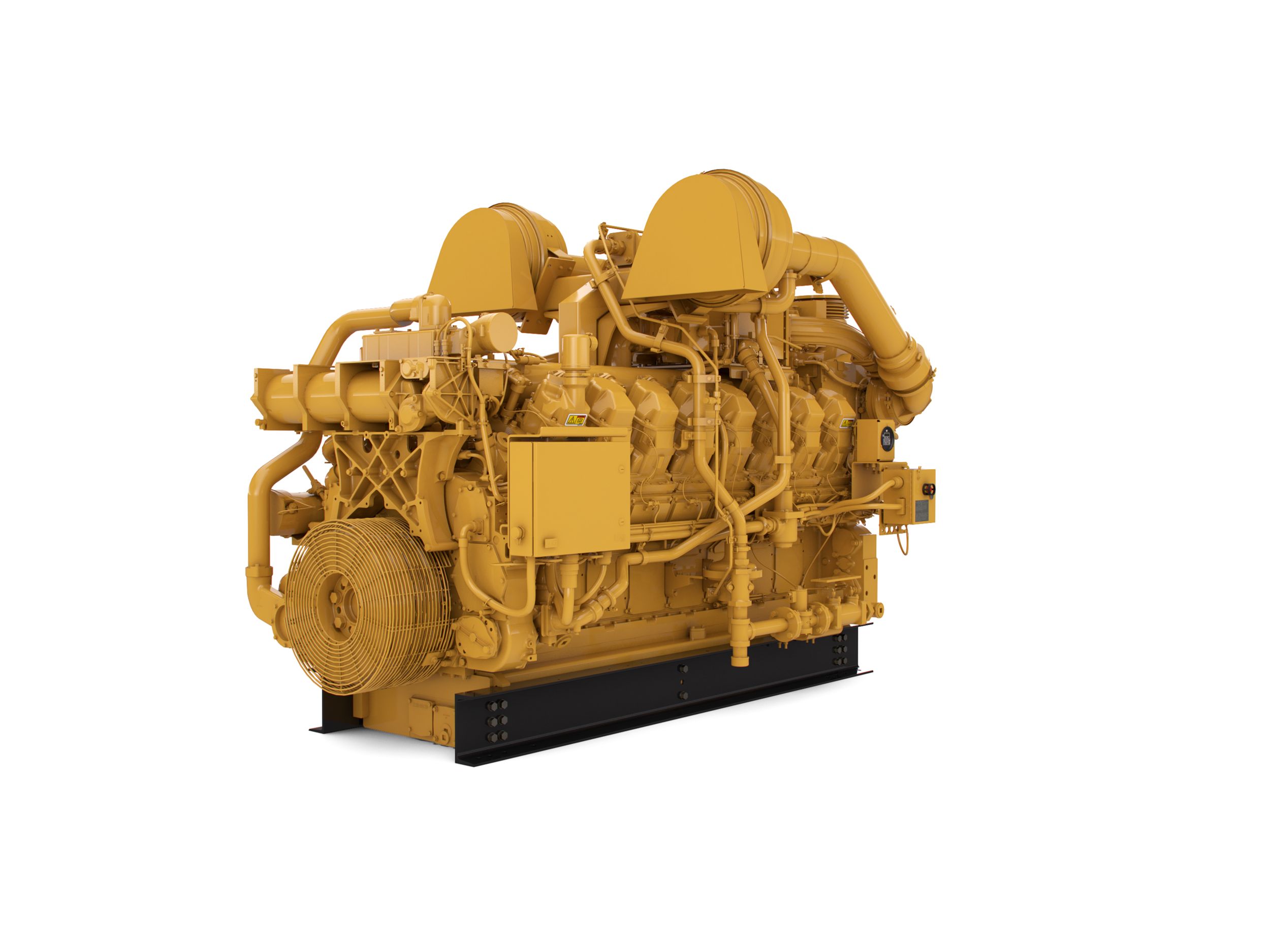

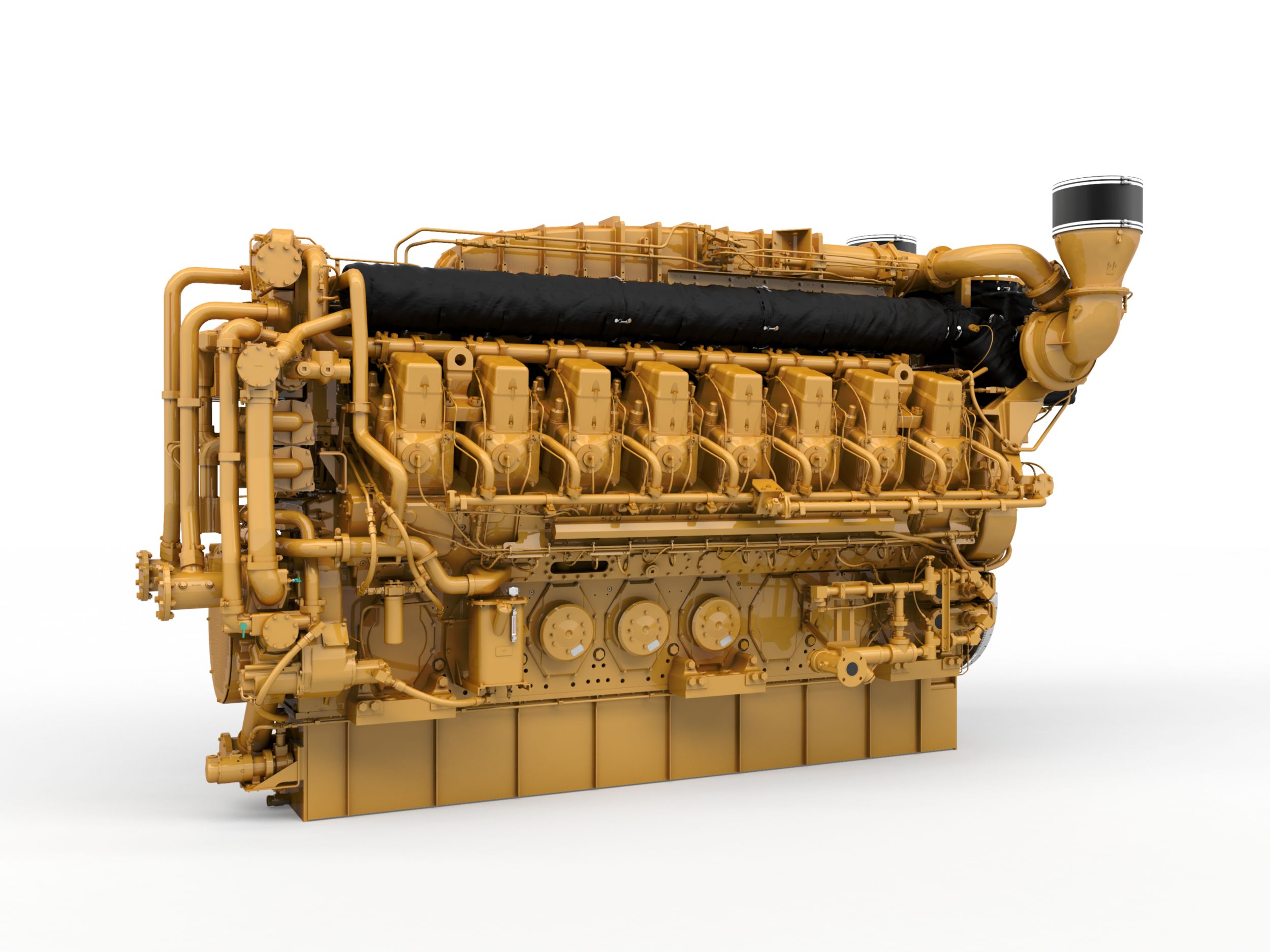

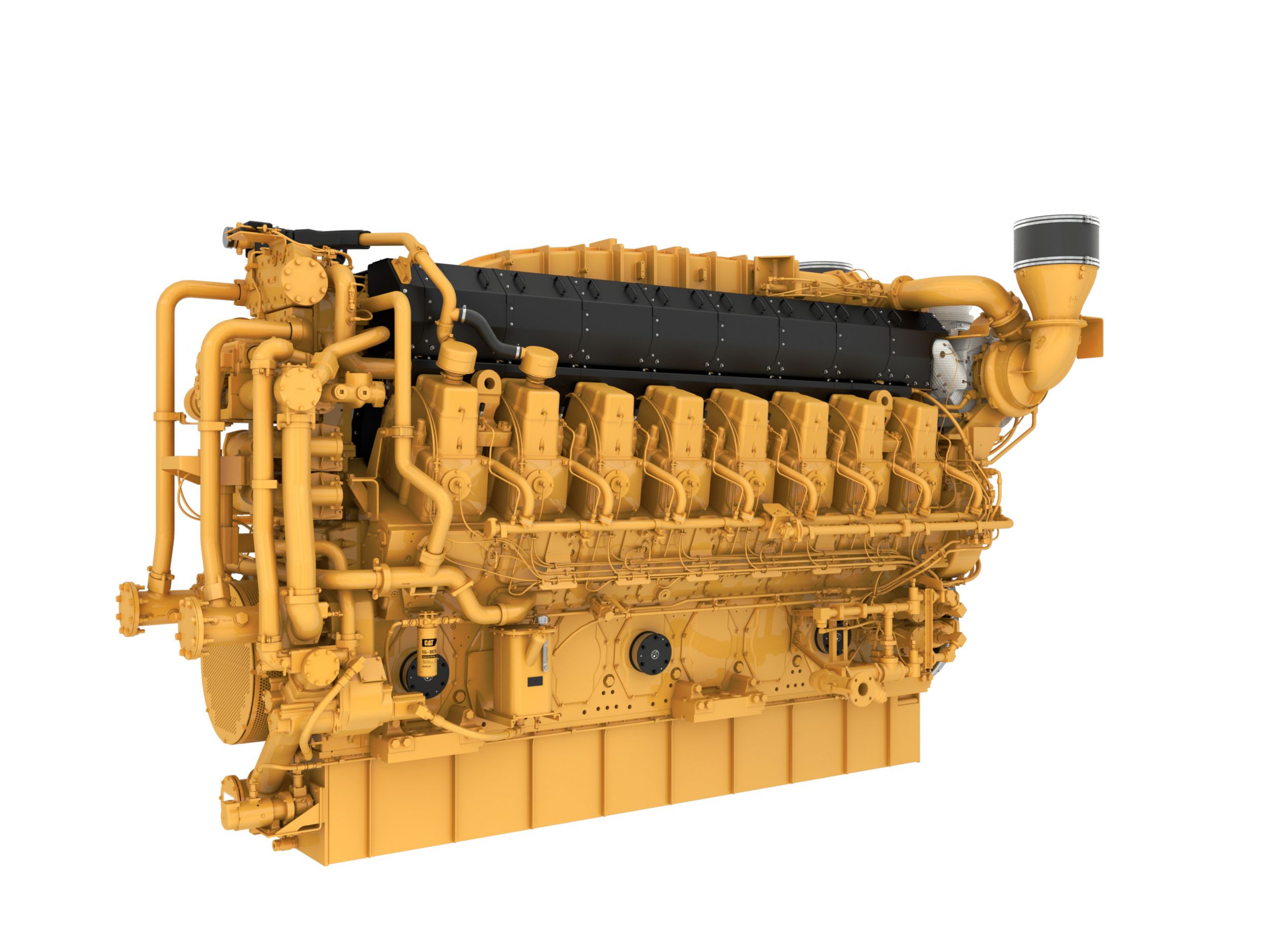

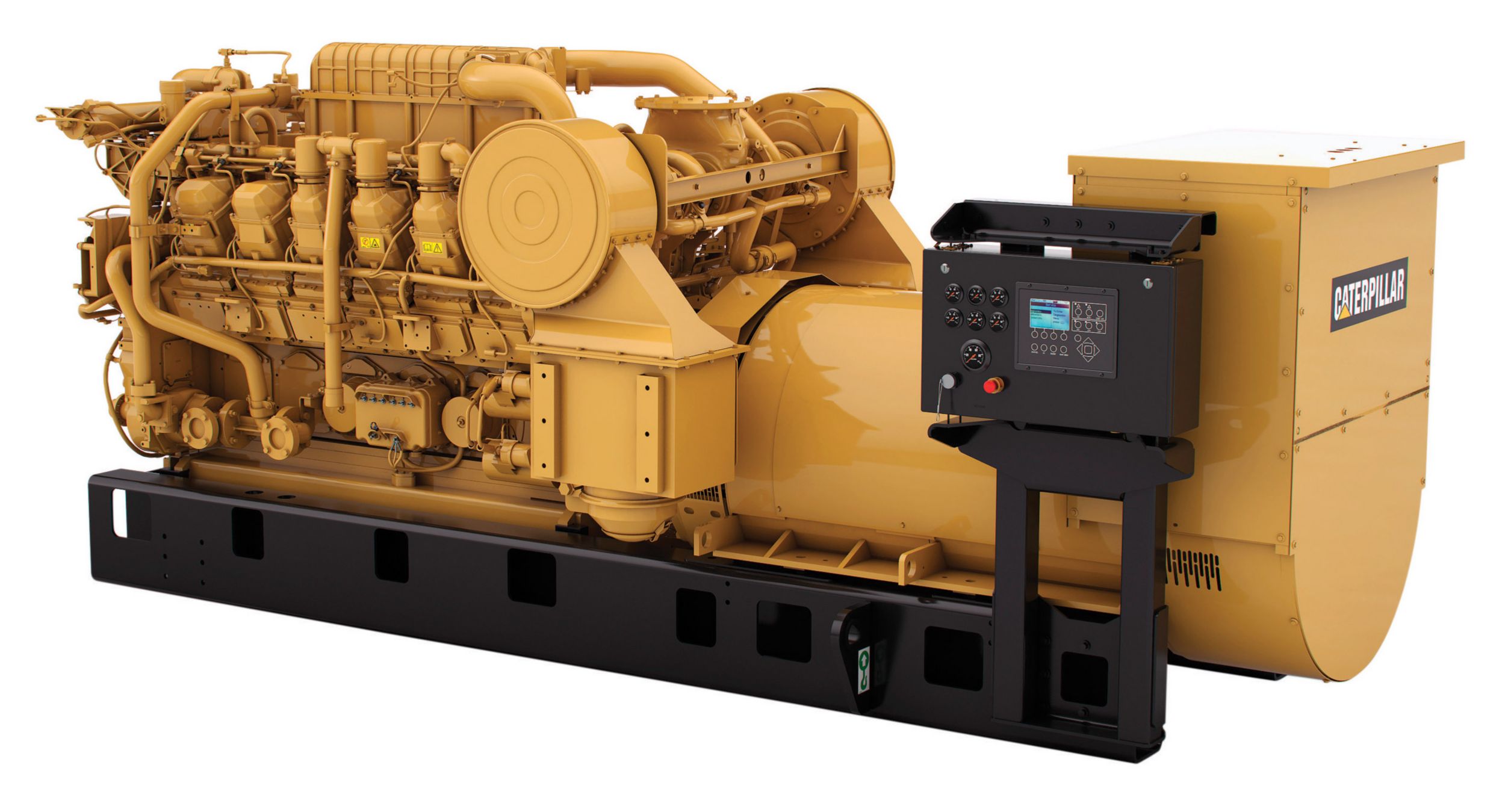

GAS COMPRESSION PROVIDER CREDITS MUCH OF ITS GROWTH TO CAT® G3600 A4 ENGINES

Sometimes, timing really is everything.

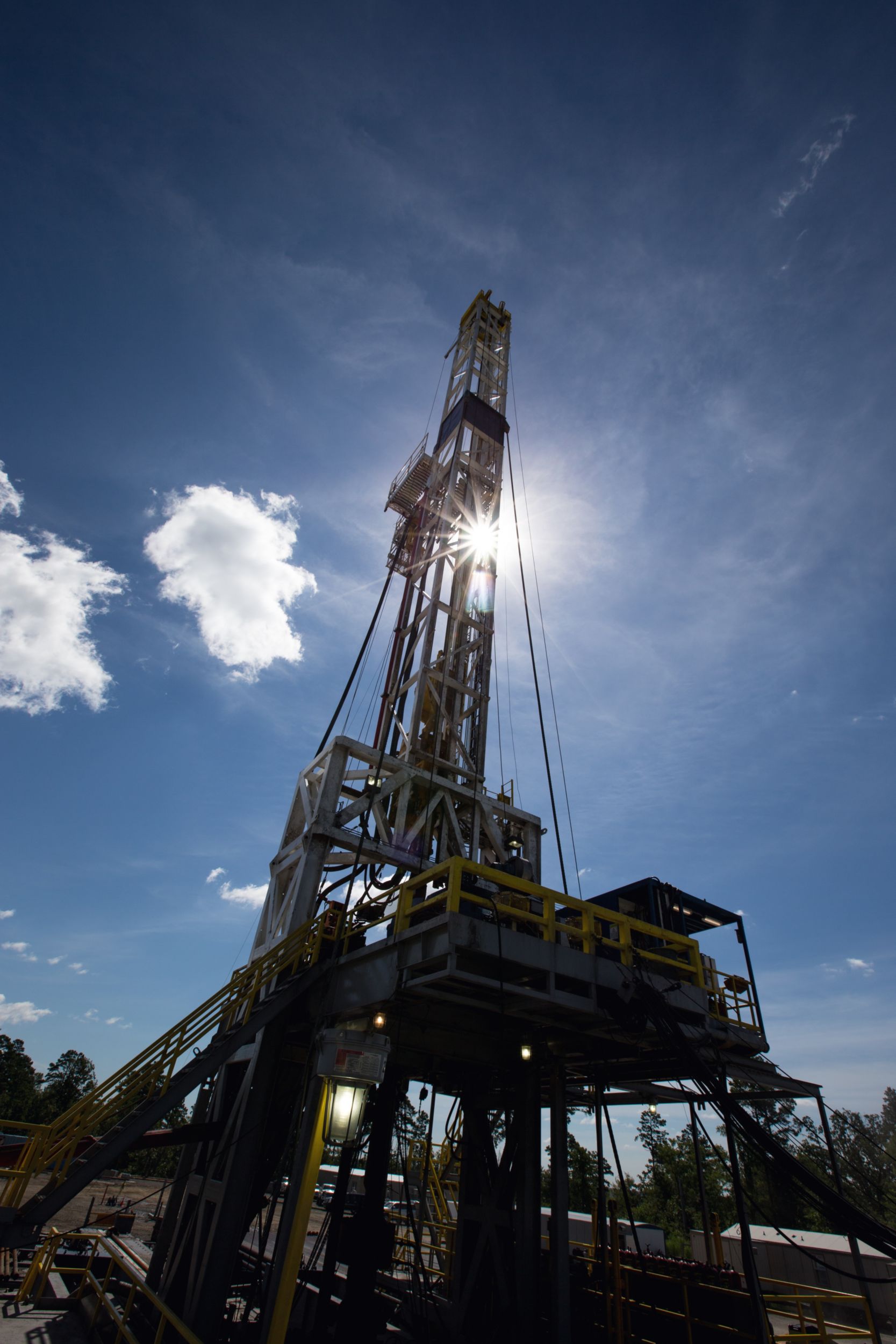

Pegasus Optimization Managers, a Texas-based natural gas contract compression and solutions provider, got its start in 2015 — the same year the market turned downward and Caterpillar opened the order board for a new engine platform, the G3600 A4 series. Both worked in the new company’s favor.

“We were very fortunate with the timing,” says Justin Head, vice president of sales and marketing for Pegasus. “Because of the downturn, a lot of our competitors came home, and we were able to be the only purchaser of A4s in the U.S. at the time. That set us apart from the competition and gave us a good foothold in the market.”

That was four years ago. By the end of 2019, Pegasus will have approximately 250 Cat® G3600 A4 engines at work across the United States, and the company has already ordered additional units for delivery in the first quarter of 2020.

“It’s a superior engine to anything else out there,” Head says. “The key to our success is the A4 engine.”

Ideal for high BTU applications

Many features set the G3600 A4 series apart, according to Head, but the best feature “by far” is the fuel flexibility that makes the platform an ideal performer in the shale plays or anywhere with high BTU fuel content. Thanks to a piston that enables a lower compression ratio and the addition of a two-stage aftercooler, A4 engines can operate on the broadest spectrum of fuel gas available.

“The controls are great — the way it operates off the ECM [Electronic Control Module],” Head says. “If there’s an issue on the fuel side, or if the temperature changes rapidly, which happens quite a bit in south Texas, it’s able to adjust rapidly and just keep rolling.”

Early on, when Pegasus sent several G3600 A4 engines to a south Texas customer who planned to use a skid to collect natural gas liquids (NGLs), Head ran a simulation to see what might happen to the engines if the skid were to fail.

“The engines never went down or even hiccupped — they just kept right on rolling,” he says. “They can handle all kinds of different scenarios.”

Added power without added cost

The G3600 A4’s added horsepower is another big benefit for Pegasus, which is seeing demand for power rise among its customer base. Previously, the company often banked four G3516 engines together to run a gas compression station because they delivered more horsepower per dollar than the G3600 series. Now, with the A4 available, Head says they can to do the same job with just two G3606 engines.

Pegasus is also taking advantage of the A4 engine’s ambient-based rating capability option — which allows for up to a 7% power increase regardless of location — to give its customers additional power without increasing footprint or cost.

“In the Marcellus and Utica shales, we’re running all our A4s at 1950 horsepower,” Head says. “We’re testing some at 2010 horsepower in south Texas right now to see how they’ll hold up. We’ve seen no problems or maintenance issues so far.”

A history of reliable performance

Speaking of maintenance, that’s another selling point for the G3600, according to Head. Pegasus’s founding partners began running the engine series back in 1997 when they worked for another gas compression firm. More than two decades of experience with the platform has given them great confidence in its reliability.

“We’re able to run a G3606 engine for 12 years without an overhaul,” Head says. “We were overhauling every four years with other engines, so we’re saving three times the maintenance expenses and downtime.”

That kind of history with the G3600 platform was a big reason Pegasus jumped on the new A4 series when it was released in 2015.

“The G3600 has been a phenomenal engine over the course of the past 25 to 30 years,” Head says. “The A4 added some great features to an already solid foundation. It does everything I expected it to and more.”

Related Articles

-

Alamo Counts On Caterpillar 24/7/365

For its operations in the Permian Basin, Alamo Pressure Pumping relies on field-proven Cat engines, transmissions, power ends and fluid ends for fast, easy, trouble-free operation.

Learn More -

An Innovative Solution to the Flare Gas Capture Challenge

With 3.5% of the world’s natural gas wasted through flaring, GTUIT producers are looking for alternatives. A solution at work in the Bakken oilfield is delivering dual economic and environmental benefits.

Learn More -

An Onboard Solution for Offshore Overhauls

Shipped to an offshore drilling rig at repair time, the C175 Support Container solves the problems — delays and revenue loss — typically created during onboard engine overhauls.

Learn More -

Bakken Shale: Rise and Fall and Rise

Bakken productivity in North Dakota is, well ... back. The 'active drilling rigs number,' 29 in April 2016, is now above 50 and new-well oil production per rig is up to 1,470 barrels a day.

Learn More -

Bundled Repair Solutions For Well Service Customers

Caterpillar provides value to its oil & gas customers with a variety of well service offerings, including bundled repair kits, foundational kits and reman engines.

Learn More -

CAT® OIL & GAS PRODUCT SUPPORT - GAS COMPRESSION BUNDLED REPAIR SOLUTIONS

Cat® 3516 Gas Compression Bundled Repair Solutions are designed to make ordering overhaul parts easy. Every part is backed by dealer support —wherever you are.

Learn More -

Cat Dealer Eneria Cat’s Power Solution Helps Global Energy Company Reduce Risks Off the Coast of Africa

Providing power in the Moho Nord Field off the coast of Africa, an ATEX Zone 2 hazardous area, means dealing with strict safety requirements. The team at Cat dealer Eneria was up to the challenge.

Learn More -

Cat Valves and Seats : Designed To Last

Caterpillar well stimulation customers depend on reliable products to keep their business in operation 24 hours a day.Cat Valves and Seats are designed to last so maximum uptime can be achieved without concern

Learn More -

Caterpillar and Reagan Power: An Electric Partnership

Caterpillar and Reagan Power: An Electric Partnership

Learn More -

Crestwood Adds Electric Motors, Drives Down Costs & Emissions

With 60% of its in-the-field horsepower coming from Cat® gas reciprocating engines, Crestwood is no stranger to Cat power. But Cat electric motors are new — and delivering on all their promises.

Learn More -

Customer Feedback Makes A Good Gas Compression Engine Better

A big fan of Cat® G3520 engines, Texas mid-streamer Energy Transfer recently had a chance to test out the new J model and reports big benefits in maintenance, life and overall performance.

Learn More -

Disruptors and Their Combustibles

Combustible hydrocarbons are cooked up for us in sometimes hard-to-reach kitchens: the history of how we've learnt to break into these kitchens is as fascinating as the endeavor itself is important.

Learn More -

Disruptors and Their Combustibles - Deal making In and For the Permian Basin

The introductory article of "Disruptors and Their Combustibles" takes a look at the recent exploratory activity in the Permian Basin .

Learn More -

Disruptors and Their Combustibles - Natural Gas on the CERAWeek Agenda in Houston

From Texas, to Israel, to Sri Lanka and on around the globe, natural gas meets the needs of a world far from ready to zero out carbon emissions - CERAweek agenda.

Learn More -

Disruptors and Their Combustibles: NG Reserves as New as the Headlines; Old as the Miocene

The waters of the eastern Mediterranean, and many of the layers of sediment on its floor, lie on top of a lot of natural gas , enough to change the economics of the whole region.

Learn More -

Dynamic Gas Blending. Dynamic fuel savings.

The unique Cat® Dynamic Gas Blending™ process helps drilling segment customers reduce their fuel consumption. By replacing diesel fuel with gas, companies can lower their owner/operator costs safely and efficiently.

Learn More -

Emissions Upgrades Supported by MTF

Emissions upgrades may be eligible for partial funding through the Mitigation Trust Fund (MTF), helping convert select Cat 3500 engines to EPA Tier 2 standards.

Learn More -

Four Reasons to Commission Your G3600 Engine with Caterpillar

Here are four reasons to turn to a professional certified by Caterpillar or a Caterpillar factory commissioning engineer to ensure your engine’s ready to perform to its full potential.

Learn More -

GRADE-SCHOOLERS BRING LEGO-INSPIRED INNOVATIONS TO CATERPILLAR HOUSTON OFFICE

The Caterpillar Houston office played lego league host to its first ever FLL Jr. Invitational — giving kids an opportunity to show off their creativity and exposing them to Cat® technology at the same time.

Learn More -

Get the Full Picture with the Cat Gas Engine Rating Pro (GERP)

The Cat Gas Engine Rating Pro, or GERP, software has long been a mainstay among clients in the gas compression industry. Launched in 2004, GERP was among the first computerized site rating calculators to help gas compression clients in sizing the right engine for their jobsite. And to this day, GERP remains the industry standard, with organized and comprehensive datasets that cover nearly every possible scenario.

Learn More -

Holt Turbo Rebuild Center Interview

We talked with a product sales support manager and lead technician from Holt Cat about the dealer’s new Turbo Rebuild Center.

Learn More -

How Ambient-Base Ratings Increases Your Revenue

When Revenue "more power" means "more money," increasing power without increasing costs makes good business sense and revenue. And that’s just what Caterpillar's "Ambient-Base Rated" G3600 series does: simply deliver more power. The Ambient-Based Rating (ABR) capability, optional on all G3600 A4 platforms, operates in real-time, measuring temperatures and reacts accordingly, allowing for up to a 7% power increase, regardless of location. While the engine is taking advantage of higher charge densities and dynamically making adjustments without calibration, you’re making money.

Learn More -

In Arctic Conditions, Cat® Generator Sets Prove as Tough as the Oilfield Workers Who Rely On Them

100mph winds. Temps as low as -60°F. Drifting snow. Workers at Black Gold Oilfield Services in Alaska face these conditions all winter long. So do the Cat® generator sets that power the camp where they live.

Learn More -

Innovative Mobile Units Help Reduce Emissions & Keep Oil Wells Operating at Full Capacity

In a remote area of the Bakken oilfield, innovative mobile gas capture units from GTUIT are helping Cat customer Enerplus reduce emissions and keep its oil wells operating at full capacity.

Learn More -

Kuwait Land Drilling Company Turns Cat® Connect Data into Tangible Actions

Learn more about Kuwait Land Drilling Company Turns Cat® Connect Data into Tangible Actions

Learn More -

Myth Buster: Tier 4 Final Doesn't Always Equal Urea

It’s a common misconception that all U.S. EPA Tier 4 Final well service engines require Diesel Exhaust Fluid, or urea. But Cat® engines rated above 750hp don’t. Here’s why.

Learn More -

Natural Gas Producers Use Cat Productivity Optimizer to Reduce Downtime & Costs

With the web-based Cat Productivity Optimizer, natural gas producers have the real-time data they need to reduce downtime, lower maintenance costs and explore new ways to boost gas production.

Learn More -

Never Stop Improving: The Difference in the G3600 ADEM™ A3 vs new G3600 ADEM A4

In the power business, 12 years is a long time, and in the 12 years since the G3600 A3 was released, there’s been major developments in the industry. The G3600 A4 has been designed with these developments in mind, and the result is an improved version of an already formidable engine.

Learn More -

New Cat® HazPak Is a Safe Solution for the Oil and Gas Industry

An Australian company recently chose two Cat® HazPaks for its offshore application and got them in less than 12 weeks, thanks to hazardous-location certification from the factory.

Learn More -

Oil & Gas Single Source Benefits

Hear from a Cat Oil & Gas customer, Jared Oehring, discuss the benefits of using a single source supplier for all equipment needs.

Learn More -

Petroleum Geology: The Consensus Happens to Be Right

Nearly all petroleum geologists agree that the oil and gas to be found beneath the surface of the earth is there as a result of the death of once-living creatures and the sedimentary entrapment of their carbon molecules. Here’s a look into oil geology and the origin of petroleum.

Learn More -

Power Profile – Southern Pines

Southern Pines, located in Leakesville, MS, is a natural gas storage facility pioneering the Solution Mining Under Gas (SMUG) technique. As a peak service facility, it responds to high load potential over seasonal, daily, or monthly intervals.

Learn More -

Reduction in Gas Flaring Earns Cat Customer a World Bank Excellence Award

Using innovative technology from GTUIT, Cat customer Hess Corporation is reaping the environmental and economic benefits of reducing gas flaring—earning a World Bank excellence award in the process.

Learn More -

Sichuan Shale and the Chinese Appetite for Clean Fuel

The People’s Republic of China has set a target of producing 30 billion cubic meters per year of natural gas from shale by 2020—that’s 21 billion more than they produced last year. Here’s a look into why they set their sights so high and how they plan to do it.

Learn More -

Smart Engine Management Revolutionizes Rig Performance

As in many industries, old-style controls don't always keep up with evolving technology. Land drilling rigs are about to take the next step.

Learn More -

Switch to Cat valves & seats boosts revenues for oilfield services company

After trying out four different brands of valves and seats in its pumps, J4 Oilfield Services saw immediate improvements after making the switch to Cat® products—including three times the life.

Learn More -

The Difference in OEM Dual Fuel Solutions

Caterpillar’s dual fuel solution for oil & gas customers is Cat Dynamic Gas Blending (DGB) and is offered on the 3500 engine platform in land drilling, production and well service applications.

Learn More -

The Magic of Urethane

Find out how urethane optimizes Caterpillar’s valve and seat assemblies

Learn More -

The Right Blend

We treat people right.” Many companies say it. Fewer put the words into action. Fewer still extend that promise to those who purchase and operate their products. Then there’s Keystone Synergy.

Learn More -

Tier 4 Final DGB™ Field Gas Project Is a Success

See how Cat® Dynamic Gas Blending™ engines and GTUIT mobile gas treatment delivered big fuel savings, emission reductions and safety benefits on a Texas frac site.

Learn More -

Turbochargers for Gas Compression

Two of our engineers discuss how Cat® turbochargers can help boost performance, efficiency and longevity of gas compression engines.

Learn More -

What are the latest trends in oilfield power

Electrical power is required in the oilfield for a variety of purposes, from illumination to process heating to pumping of water and oil. Depending on the availability and reliability of local infrastructure, this power may be sourced from a grid, from "alternative" technologies like solar panels, from generator sets, or from a combination of the above.

Learn More -

Why the G3600 ADEM A4 is an Industry Game Changer

The G3600 series has become synonymous with reliable performance, logging over 150 million hours in the field as a preferred solution for gas compression. In 2015, Caterpillar engineered the platform beyond expectations by drastically increasing all critical performance factors and unveiling the G3600 ADEM A4 engine across all four configurations. The new platform is a game-changer for the industry, incorporating the most substantial updates made to the gas compression platform in its noted history. Here’s why:

Learn More -

With Cat® Product Link™, Equipment Manager Finds He Can Be Everywhere at Once

McVay Drilling Equipment Manager Dominik Mendoza is just one man. But with Cat® Product LinkTM, he can keep an eye on rigs located across New Mexico and Texas—and keep downtime to a minimum.

Learn More