Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

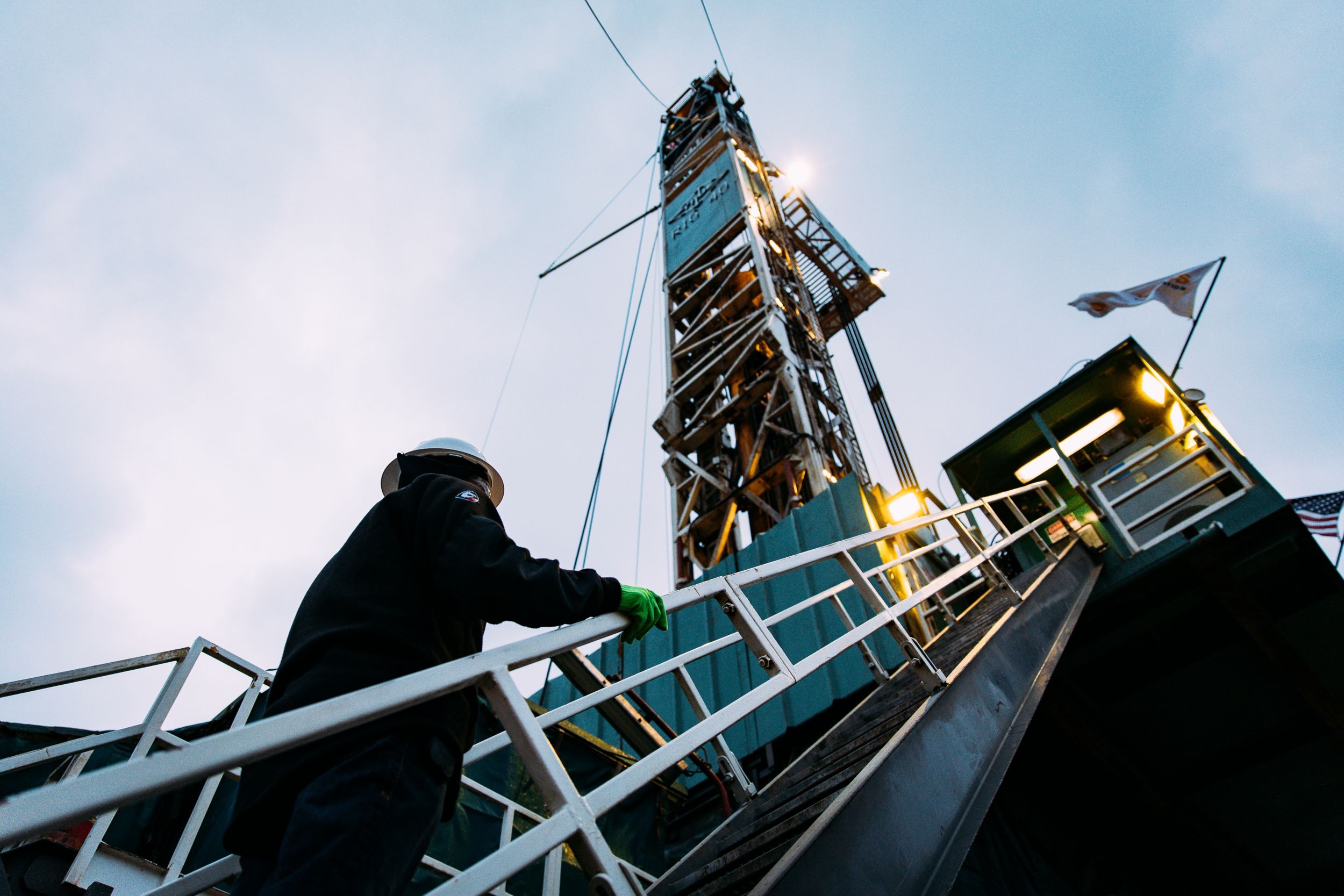

Cat® Smart Engine Management System—The Smarter Way To Run Drilling Engines

Parts & Services

-

Cat® Engine Lifecycle

Learn More -

Extend the Life of Cat® Oil and Gas Equipment

Learn More -

Protect Your Cat® Investment

Learn More -

Maintain Equipment Performance

Learn More -

Monitor your Oil and Gas equipment with Cat® Connectivity

Learn More -

Oil and Gas Education for Technicians

Learn More -

Finance and Warranty for Oil & Gas

Learn More

Sustainability

About

You know running all the engines on your drilling rig continuously is an inefficient way to operate, driving up fuel and maintenance costs. But, ensuring you’re getting power when you need it isn’t easy, right?

It is easier, now. With Smart EMS from Caterpillar, you can reduce engine runtime on your drilling rigs up to 25 percent, cut fuel consumption up to 10 percent and improve diesel displacement up to 15 percent—all without sacrificing power, performance or productivity.

How Smart EMS Works

“EMS” is short for Engine Management System, and “Smart” means just that. Developed exclusively for land electric drilling rigs—with more than 25,000 hours of field validation—Smart EMS monitors rig demand and engine load continuously, then efficiently matches supply to demand.

If power demand from the rig is low, Smart EMS turns engines off. If demand is high, it turns engines on. And, it all happens automatically so your rig crew can focus on drilling. Plus, by providing remote access to engine controls—eliminating the need to enter the engine room to start and stop engines manually—Smart EMS improves safety at the rig.

6 Ways You Benefit With Smart EMS

- Lower fuel and maintenance costs: Smart EMS eliminates the debate about how many engines need to be online at any given time because it automates the process, optimizing performance and operating costs based on programmable targets. Fewer engines running at higher loads is more efficient, reducing fuel consumption. And, decreasing runtime means you don’t put as many hours on your engines—so you spend less time and money on maintenance and repairs.

- Fast payback: By driving significant fuel and maintenance cost reductions, Smart EMS is designed to pay for itself in less than a year. It can also save you money on capital expenditures during rig builds or upgrades by eliminating the need for third-party engine controllers.

- Higher diesel displacement: If you’re running engines with the Cat® Dynamic Gas Blending system, Smart EMS keeps them operating at a higher load, which improves diesel displacement.

- User-friendly interface: Smart EMS’s human-machine interface (HMI) provides all the information operators need on an easy-to-read, easy-to-control touchscreen panel. Customers can install multiple HMI in the drillers cabin or the rig power house to provide remote access to the engines.

- Easy installation: Integrating Smart EMS into your drilling rigs is a quick process, with little to no downtime required if installation takes place during a rig move. The transition for rig operators is seamless, too.

- Proven technology: Numerous rigs equipped with Smart EMS are already running successfully in the field, and the control panel has been fully validated in both the electric power and oil and gas industries.

Running Smart EMS on your engines requires EMCP 4.4 digital controls technology, which is available as part of DGB upgrade kits or as an option for new Cat constructed power modules.

6 Ways You Benefit With Smart EMS

Running Smart EMS on your engines requires EMCP 4.4 digital controls technology, which is available as part of DGB upgrade kits or as an option for new Cat® constructed power modules.

Lower fuel and maintenance costs

Smart EMS eliminates the debate about how many engines need to be online at any given time because it automates the process, optimizing performance and operating costs based on programmable targets. Fewer engines running at higher loads is more efficient, reducing fuel consumption. And, decreasing runtime means you don’t put as many hours on your engines—so you spend less time and money on maintenance and repairs.

Fast payback

By driving significant fuel and maintenance cost reductions, Smart EMS is designed to pay for itself in less than a year. It can also save you money on capital expenditures during rig builds or upgrades by eliminating the need for third-party engine controllers.

Higher diesel displacement

If you’re running engines with the Cat® Dynamic Gas Blending system, Smart EMS keeps them operating at a higher load, which improves diesel displacement.

User-friendly interface

Smart EMS’s human-machine interface (HMI) provides all the information operators need on an easy-to-read, easy-to-control touchscreen panel. Customers can install multiple HMI in the drillers cabin or the rig power house to provide remote access to the engines.

Easy installation

Integrating Smart EMS into your drilling rigs is a quick process, with little to no downtime required if installation takes place during a rig move. The transition for rig operators is seamless, too.

Proven technology

Numerous rigs equipped with Smart EMS are already running successfully in the field, and the control panel has been fully validated in both the electric power and oil and gas industries.

Related Content

-

EMCP 4.4

If you’re still using EIP (Electronic Instrument Panel) to monitor your rig’s engines, it’s time for an upgrade. This easy-to-use control panel, proven in the electric power industry, simplifies diagnostics and troubleshooting.

Learn More -

Transitioning Onshore Drilling Rigs to EPA Tier 4 Final Engines

Use this white paper to compare the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine to the previous Tier 2 model, the 3512C, as you prepare to transition your rigs to meet emissions standards.

Learn More -

You asked, We Delivered

Land drilling customers told us they had five big requirements for Tier 4 Final engines — here’s how the 3512E delivers on all of them.

Learn More