Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® G3600 Upgrade Kits

Parts & Services

-

Cat® Engine Lifecycle

Learn More -

Extend the Life of Cat® Oil and Gas Equipment

Learn More -

Protect Your Cat® Investment

Learn More -

Maintain Equipment Performance

Learn More -

Monitor your Oil and Gas equipment with Cat® Connectivity

Learn More -

Oil and Gas Education for Technicians

Learn More -

Finance and Warranty for Oil & Gas

Learn More

Sustainability

About

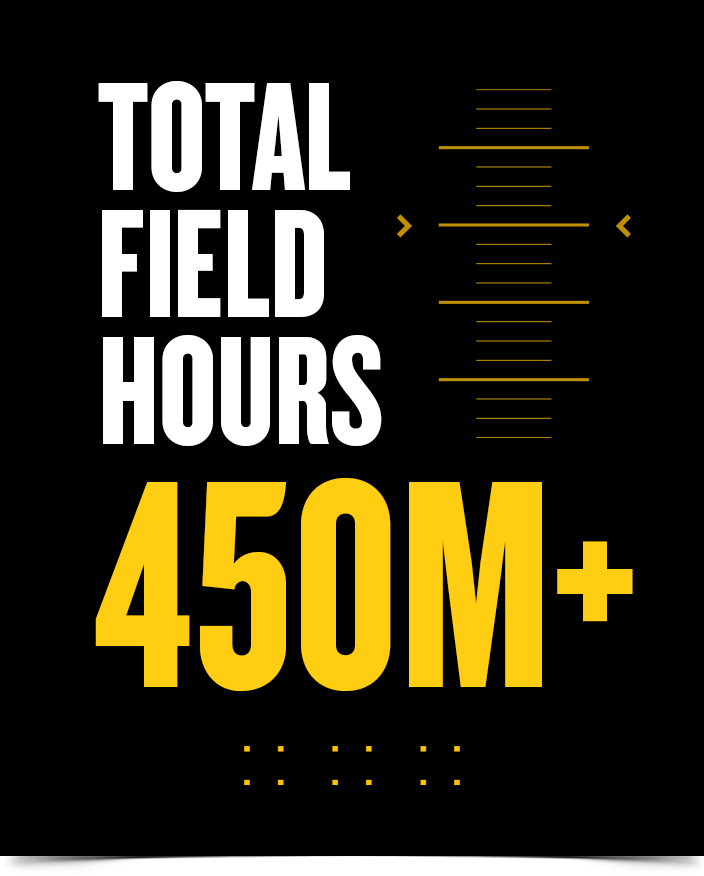

Trusted for Decades. Upgraded for Today.

Extend the life of your engine or maximize its performance with these Cat® G3600 upgrade options. Forget piecing together individual components; Caterpillar simplifies the hassle of sourcing individual parts with meticulously crafted upgrades tailored to your needs.

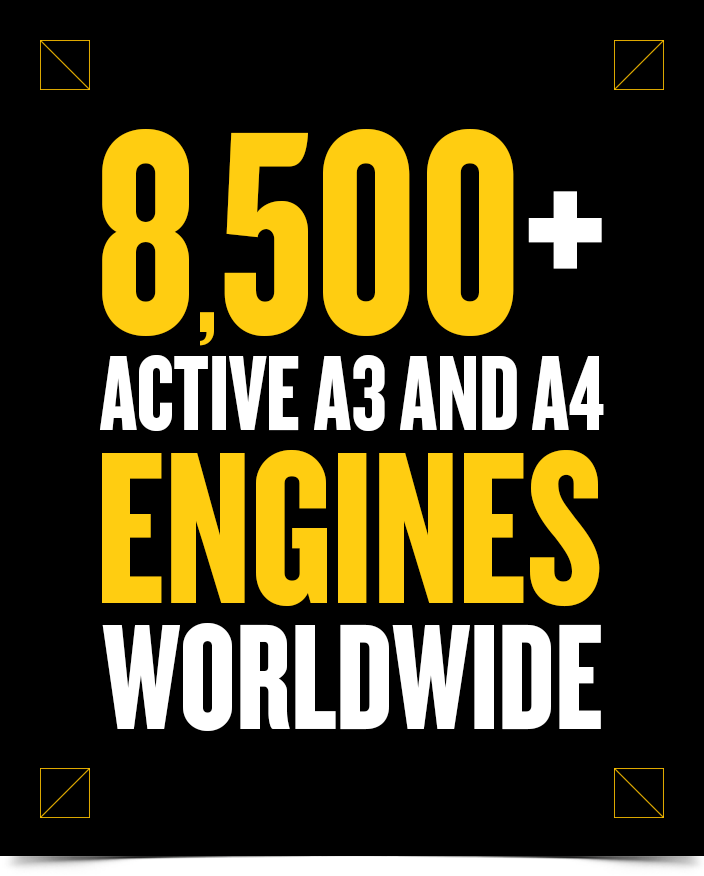

Enhance your existing G3600 A3 or A4 models to meet the performance standards of today. Trust Caterpillar to deliver unmatched reliability and power. Our most recent upgrade kits not only optimize performance but also help meet customer sustainability goals, giving lower emission options without compromising throughput.

Unlock the full potential of your engine, and safeguard your investment with Caterpillar-specific upgrade kits. Explore how our solutions can drive success for your equipment and bottom line. Dive in below, and take your engine to the next level.

“The Cat® G3600 gas compression engine is known for dependable power, and Caterpillar is known for longevity in the Oil and Gas industry. We understand that no matter the current climate, Caterpillar can help weather the storm.” - Ray Purtzer, VP Asset Management at Archrock

Closed Crankcase Ventilation (CCV) System

The Cat Closed Crankcase Ventilation (CCV) System, a field-proven technology, is designed to eliminate the venting of crankcase gases, commonly referred to as blow-by emissions, from internal combustion engines.

Specifically designed for Cat G3600 solutions, the engine-mounted CCV system holds multiple unique patents that distinguish it from conventional CCV approaches. It can be applied at any time with minimal downtime.

The CCV System for G3600 A4 engines is currently available to order as a retrofit kit, and the system is scheduled to be standard on all new G3600 A4 Gen 2 engines starting January 2025. The CCV System for G3600 A3 engines is planned to be released in late 2025.

Features & Benefits:

- Eliminates crankcase emissions

- Easy to install as a bolt-on retrofit at any time

- Operational in low ambient temperatures with minimal risk of condensation

- Reduces up to 20% methane emissions from gas engine*

- 8,000-hour filter change service interval

- Reduces lube oil consumption

- Helps eliminate facility contamination

- Longer service intervals

- Maintains crankcase pressure at 0 kPa

* Using OEM data, Reflect G3608 A4, 0.3 g/bhp∙hr NOx, 8760 hours/year, 24 hours labor hours x 2 technicians to install CCV system & package changes, service cost

A3 Gen 2 Upgrade

Caterpillar first released G3600 engines into the field in 2002, and the A3 has been an active player ever since. With the latest A3 upgrade kit, your engine will experience updated emissions benefits compared to the original A3 model. This kit can be applied at any time but is most cost-effective when applied at a major overhaul (recommended around 100,000 hours). Extend the value of your existing engine today.

Features and Benefits:

- Features advanced combustion technology

- Updated piston, rings, liner and pre-chamber design

- Lower emissions through reduced crevice volumes and improved combustion

- Cuffed liner to reduce risk of carbon deposits

- Emission reduction in GHGs, VOCs, CO2 and formaldehyde

- Helps existing engines meet regulatory emissions requirements

- Maintains the same engine maintenance intervals with updated hardware

- Available in both 0.5 g/bhp∙hr and 0.7 g/bhp∙hr NOx ratings

- Most cost-effective when applied at in-frame and major overhaul

A4 Gen 2 Upgrade

The Cat A4 Gen 2 kit was designed to keep your engine relevant. This kit is stacked with options, allowing you to customize your kit based on what’s most important to you—whether that’s emission reduction, optional horsepower or increased altitude capabilities. With tested and vetted parts customers have come to trust, the Gen 2 kit extends your investment while delivering on improved emission reductions and durability. Upgrades can be performed at any time but are most cost-effective at a major overhaul (recommended every 100,000 hours).

Features and Benefits:

- Features advanced combustion technology

- Updated piston, rings, liner and pre-chamber design

- Lower emissions through reduced crevice volumes and improved combustion

- Cuffed liner to reduce risk of carbon deposits

- 10% horsepower uprate, optional through engine software rating selection

- Emission reduction in methane, GHGs, VOCs, CO2 and formaldehyde

- Helps existing engines meet regulatory emissions requirements

- Need-based customer options

- Option 1: Emission reduction only, no horsepower increase or turbocharger change

- Option 2: Emission reduction, 10% more horsepower and increased altitude

- Maintains the same engine maintenance intervals with updated hardware

- Available in both 0.3 g/bhp∙hr and 0.5 g/bhp∙hr NOx ratings

- Most cost-effective when applied at in-frame and major overhaul

- Base horsepower offering (Option 1) allows users to take advantage of emissions benefit while maintaining standard compressor match and package layout

Thermal Management System Upgrade

Strengthen your reliability with the Thermal Management System for G3600 A4 engines. With innovative shielding technology, this kit provides a more secure fit for your product. Your G3600 engine will get increased durability (up to 20,000 hours) when compared to the average lifespan of the soft-wrap insulation (up to 5,000 hours), a reduced surface temperature and an easier assembly/disassembly process.

Features and Benefits:

- Stainless-steel shell foil inner layer and sheet-metal fabricated outer heat shields, providing increased safety due to reduced metal temperatures in high-maintenance areas

- Easier to assemble/disassemble, with a modular and segmented design

- Overall tighter fit compared to soft-wrap design

- Enhanced resistance to high-pressure washing and associated chemicals

- Fleet commonality

- Improved service intervals

- Consistent repositioning after maintenance and repairs

G3600 ESS To A3 Upgrade

This kit condenses controls for detonation, engine sensing, ignition and air/fuel ratio into one improved system, giving you improved performance and reliability. Advanced Digital Engine Management (ADEM) 3 monitoring capabilities enable a simplified approach to viewing engine parameters. You can access all types of field program performances from any jobsite, reduce engine wear and maintain consistent control through your operation.

Features & Benefits:

- Single interface for operator using Advisor Panel

- Centralized points to reduce number of electrical faults

- Improvement of wiring harnesses and fewer terminal connections

- Fewer independent control modules

- Closed-loop choke control

- Exhaust temperature sensing

- Easier troubleshooting

- Improved engine protection through individual cylinder detonation control

- Consistent control during light-load operations

- Reliable engine monitoring

- Reduced exhaust emissions and engine wear

- Easily monitor operating engine parameters with remote data access

- Reduced emissions possible when the A3 Gen 2 kit is applied (requires A3 Gen 1 upgrade to apply Gen 2 kit)

VTC To TPS Turbocharger Upgrade

Optimize your turbocharger experience with the G3600 Engine Turbocharger VTC to TPS Upgrade Kit. Applicable to ESS or A3 with hydrax engines in the G3600 Series, the conversion from a VTC254 axial flow to the TPS57 radial flow will reduce overall operation cost, as well as improve engine capabilities.

This upgrade reduces owning and operating costs by increasing service intervals and overall uptime while improving altitude and turndown capabilities—a clear example of our ongoing commitment to lead the industry in customer satisfaction by providing the best solutions and customer value.

Features & Benefits:

- Improved software to reduce NOx emissions from 0.7 to 0.5 g/bhp∙hr

- Alignment of service intervals with overhaul schedules

- Higher resistance to fouling

- Lengthened turbocharger lifespan

- This design has proven to be less sensitive to deposits on the turbine wheel caused by impurities in the composition of field gases

- Product is intended to improve overall value by increasing usable power, service life, and decreasing maintenance and repair costs

- Improved altitude and turndown capability

* Using OEM data, Reflect G3608 A4, 0.3 g/bhp∙hr NOx, 8,760 hours/year, 24 hour labor hours x2 technicians to install CCV system & package changes, service cost.

Boost Your Existing Assets and Make an Impact

Customer Success Stories

Engine Reliability

Trusted Network