Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Author: Small Business Expert | May 25, 2021 | Topic: Used Equipment

When it comes to running a paving business, contractors need high-performing heavy-duty equipment that stands up to tough conditions. Whether resurfacing a highway or installing a residential driveway, choosing the right paving equipment for the job is essential.

This paving equipment guide breaks down the best types of paving equipment and provides tips for choosing paving equipment for your next job. We also compare the differences between asphalt and concrete paving equipment and help you decide whether to invest in new vs. used paving equipment. No matter which type of paving equipment you need, when buying pre-owned equipment, always choose Cat® Certified Used for reliable used equipment backed by a Caterpillar warranty.

4 Best Types of Equipment for Paving

Roadwork contracts require reliable, heavy-duty equipment designed to perform various rugged tasks. From milling to reclaiming to compacting, contractors depend on different types of heavy equipment for paving. The best equipment for paving delivers high performance so you can maximize productivity, minimize costs and preserve your bottom line.

If you’re thinking of investing in road work equipment, consider the machines on this equipment list for a paving business. We cover the four common types of paving equipment and offer some tips for choosing the right equipment depending on the job.

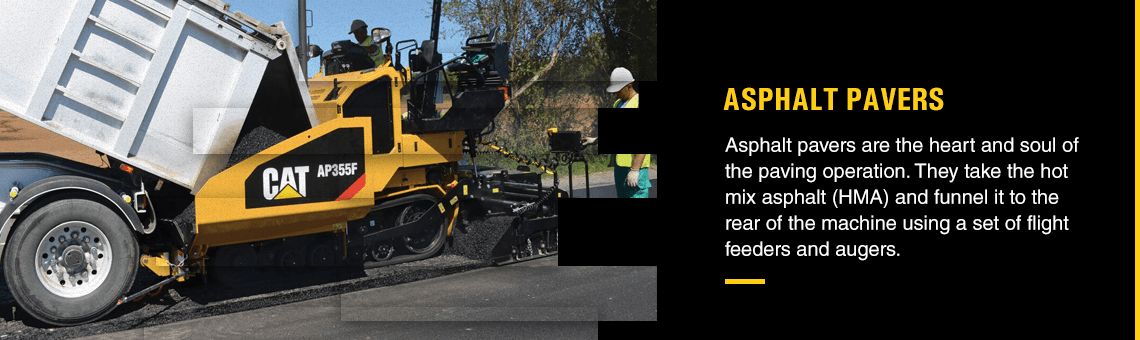

1. Asphalt Pavers

Asphalt pavers are the heart and soul of the paving operation. They take the hot mix asphalt (HMA) and funnel it to the rear of the machine using a set of flight feeders and augers. The HMA is then directed into the screed, a tool on the rear of the asphalt paver that determines the thickness and width of the HMA as it gets discharged from the rear of the paver.

Asphalt pavers are generally separated into two categories:

- Tilt hopper or gravity-fed pavers: Tilt hopper or gravity-fed pavers are smaller machines that use gravity to funnel the asphalt from the hopper down into the screed. They can typically handle between 100 and 150 tons of asphalt per day.

- Conveyor-fed pavers: Conveyor-fed pavers use a mechanized conveyor to direct the asphalt down into the screen. The conveyor allows for larger amounts of asphalt to be placed into the hopper of the paver and be directed towards the screed. Conveyor-fed pavers can handle anywhere from 300 to 500 tons per day of paving.

The amount of asphalt that tilt hopper or gravity-fed pavers can handle makes them ideal for paving residential driveways or other small areas. On the other hand, conveyor-fed pavers handle asphalt loads better suited for larger areas, such as parking lots or roadways. However, smaller units can easily pave residential driveways as well.

2. Cold Planers

Cold planers or milling machines are often the first large pieces of equipment to begin construction on a new asphalt surface. The role of the cold planer is to remove the existing asphalt so a new layer can be added.

Asphalt is typically removed from an area because it’s showing signs of decay, like cracking, sloping or potholes. When a new asphalt layer needs to be installed, the first step is removing the existing layer. Often, only some of the existing layer of asphalt needs to be removed. However, in some cases, all of the asphalt needs to be removed. The cold planer removes the existing asphalt surface with its cutting drum teeth. These teeth vary in type, number and spacing to achieve the desired amount of asphalt removal from the road surface.

After the cold planer has removed a layer of the existing asphalt, it leaves behind a relatively smooth surface that is ideal for the new asphalt the bond with. This surface is also acceptable for road traffic to use before a new layer of asphalt is installed.

3. Compactors

When a paver lays down a new asphalt surface, it needs to be compacted sufficiently. This ensures that all the air is removed from the HMA, the surface is level and smooth and the asphalt is structurally stable. Compaction occurs during multiple stages of the paving process.

The first instance of compaction occurs when the screed on board the paver lays down the layer of HMA. The screed works to smooth out the asphalt as it’s being applied to the road surface, increasing its stability and making it more uniform.

After the HMA is laid out, two different types of compaction rollers can perform compaction:

- Steel wheel rollers: Steel wheel rollers are drum rollers that typically have two drums but can come with one or three. The drums can either be static or vibrating. They range from 30 to 90 inches wide and from 1 to 20 tons in weight.

- Pneumatic tire rollers: These machines are similar to the steel drum roller but employ smooth pneumatic rubber tires for compacting the HMA surface. Pneumatic tire rollers use offset, staggered tires on each axle to ensure the entire area in the roller’s path is in contact with the tires. You can vary the compaction effort by adjusting the tire pressure, usually between 60 and 120 pounds per square inch (psi).

When using a steel wheel roller, vibrating drums are usually preferred over static ones because they better help the HMA settle and remove air pockets. This creates a more structurally stable road surface than a non-vibrating drum roller.

4. Road Reclaimers

Road reclaimers are pieces of heavy machinery that remove a layer of asphalt from the existing road surface by cutting it using multiple teeth. The road reclaimer leaves behind a trail of asphalt and dirt mixture that can then be hauled away for recycling or reclaimed and graded smooth in preparation for a new layer of HMA.

Road reclaimers are useful because the mixture of existing asphalt and dirt they leave behind is an ideal surface for new asphalt to bond to once it’s been graded and compacted. Additionally, road reclaimers can add asphalt emulsion or other binding agents during pulverization or during a separate mix pass to further stabilize the road surface.

In many instances, road surfaces in rural areas can be pulverized, graded and compacted to form temporary roadways. These are often used as a more economical option in areas that don’t receive enough traffic to justify the cost of a new asphalt surface.

Asphalt vs. Concrete Paving Equipment

Which material makes the best road surfaces — asphalt or concrete? Both materials have their pros and cons. It’s important to know the basics of each material and the equipment that’s typically used to construct roadways and other areas.

Concrete consists of portland cement, air, water, sand and gravel. The reaction between the portland cement and the water is what gives concrete its hardness. The sand, gravel and air pockets act as a solidifying matrix and improve the mechanical properties of the mixture.

Asphalt consists of two main ingredients — aggregates and bitumen. Aggregates are similar to the sand, gravel and stone contained in the concrete mixture and make up about 95% of the asphalt mixture. The other 5% of the asphalt mixture is bitumen. Bitumen is a petroleum byproduct composed of polycyclic hydrocarbons. It’s produced during the refinement and creation of other petroleum products, such as gasoline and plastics.

Cost

When looking at the initial cost, concrete surfaces are almost always more expensive. This is because concrete requires a sturdier foundation layer than asphalt due to its increased hardness. Compared to asphalt, it also tends to crack more easily due to the build-up of larger internal stresses as it cures. This requires the additional step of cutting grooves to relieve stress, which adds to the cost.

Because asphalt is a more workable material, the forces involved during the reclaiming or demolishing processes are less than what are required for concrete surfaces. As a result, the stress placed on your equipment will be less, leading to longer-lasting equipment when working with asphalt.

Longevity

Asphalt roads typically last around 10 years, which is considerably less than concrete roads at an average of 40 years. For this reason, many jurisdictions choose to install concrete roads. Despite their higher initial cost, concrete roads are the more cost-effective long-term investment.

When deciding which type of material to work with, it’s worth considering the longevity of each surface. With asphalt roads deteriorating quicker than concrete roads, the opportunity to provide repairs and resurfacing will be more frequent. It’s also an industry rule-of-thumb that asphalt roads make up 94% of the road pavement in America. Based on volume alone, asphalt equipment is likely a better option to invest in. On the other hand, if you’d prefer to stick to smaller projects, like residential driveways, then concrete equipment is a better choice.

Should I Buy New or Used Paving Equipment?

When buying paving equipment, choosing the right machine for the job is only one of the necessary decisions. The other primary consideration is whether to buy new or used equipment. Since paving equipment is a business investment, it’s important to weigh the pros and cons and determine which option will give you the best return on investment (ROI).

Here are some of the benefits of buying used paving equipment for your business:

- Value: When you buy used equipment, the primary advantage is the low upfront cost. Small businesses can often acquire used equipment more easily than they can new equipment because they either don’t require financing or the financing terms are safer to secure. Additionally, the depreciation period is over with an investment in used equipment, which is beneficial to small businesses that can’t absorb the immediate loss in asset value.

- Flexibility: Buying used equipment is also a way for businesses to maximize flexibility. Selecting from pre-owned inventory means you can acquire the right equipment right away for specialty or limited-time projects. Buying used equipment allows you to increase production quickly and recoup most of your investment if you ever need to resell the equipment later.

- Scale: You can put the money saved on your equipment purchase back into your business. A small business can use the savings to expand its fleet, take on more projects and scale its enterprise faster.

- Selection: The used market is full of many different models, giving you a high chance of finding the equipment you need when you need it. With a used equipment investment, your team can get to work right away with the best machine for the job.

When you partner with the right pre-owned equipment dealer, you’ll never compromise on quality vs. cost. A reputable used equipment dealer will help you secure the best investment and provide you with long-term value so you can stay profitable.

Why Buy Paving Equipment From Cat Used?

Buying pre-owned paving equipment can be a great business investment, helping you save on long-term costs. But it’s important to buy used heavy equipment that’s been well-serviced and can remain reliable for an extended service life. Many people invest in pre-owned equipment only to later discover mechanical problems that could have been prevented. That’s why it’s crucial to buy used equipment from a reliable source that deals in high-quality, well-maintained equipment.

When you buy Cat Certified Used equipment, you’ll find heavy equipment with a lifelong track record of maintenance, ongoing service and trusted reliability. Here are a few of the reasons to buy your pre-owned paving equipment from Cat Used:

- Cat standard servicing: Heavy equipment certified by Caterpillar has been fully inspected and thoroughly serviced. Available from your local Cat dealers, Cat Certified Used equipment comes with a transparent service history.

- Genuine Cat parts: Any servicing and parts replacements on Cat Certified Used equipment has been done with genuine Cat parts, delivering high value and reliability on all used products. Heavy equipment serviced using genuine Cat parts meets the high manufacturing standard Caterpillar is known for.

- Cat Used inventory: Cat Used offers you an extensive inventory of pre-owned and certified heavy equipment, including paving and asphalt equipment. Find exactly what you’re looking for from our thousands of machines and attachments.

- Caterpillar warranty: When you buy Cat Certified Used equipment, you’re getting a machine that’s backed by the Caterpillar warranty. This gives you peace of mind of knowing that you’re getting good-as-new performance for a dependable and long-lasting investment.

Invest with confidence in your next pre-owned paving equipment. Choose Cat Certified Used equipment that’s been built to last.

Choose Cat® Certified Used Paving Equipment

We hope our guide to paving equipment has helped you get closer to choosing the right equipment for your next project. By investing in high-quality used paving equipment, you’ll get long-term performance for better value. When you choose the right used heavy equipment dealer to partner with, you can rest assured you’re getting the best deal on paving equipment on the market.

Find certified used Cat paving equipment near you today. Browse our inventory of high-quality pre-owned paving equipment that’s backed by the Cat Used standard. You can sign up to receive email alerts and get notified when the equipment you’re looking for becomes available. You can also contact a Cat dealer near you to locate the right pre-owned equipment for you.