Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Author: Small Business Expert | August 17, 2020 | Topic: Used Equipment

For many pieces of heavy equipment, the undercarriage is one of the most important components. It supports incredibly heavy weights and enables equipment to traverse uneven, difficult terrain. The undercarriage is often the best place to go to look for signs of machine wear. With that in mind, it's no surprise the undercarriage also makes up a significant portion of a machine's value and operating cost.

Taking care of a machine's undercarriage typically makes up about 50% of the total cost of maintenance for that equipment. Maintaining the undercarriage of your excavator, track loader or other heavy equipment can help you keep these costs down through preventative action. Let's review how to maintain your undercarriage with some undercarriage maintenance tips for heavy equipment.

Benefits of Good Undercarriage Care

Appropriate undercarriage maintenance is critical to extending the life of your equipment. Whether you're working with a compact track loader, dozer or full-sized excavator, the undercarriage is vital to the life and performance of a tracked machine.

Proper maintenance to the undercarriage can offer:

- Added safety: By paying attention to the undercarriage, you have a better opportunity to catch and fix issues before they become safety concerns. Fluid leaks become environmental hazards, while functional issues could put operators and nearby workers at risk.

- Maintained value: Keeping the undercarriage in good condition is a critical part of retaining the resale value of your machinery. Since it is such an important component, it has a significant influence on how much you'll get back for the overall machine.

- Minimal repairs: Maintenance prevents problems that can cause extensive damage and require costly repairs or replacements. Keeping fluids changed, components clean and tracks tightened, among other tasks, are key to keeping repair costs down and avoiding damage to your heavy machinery.

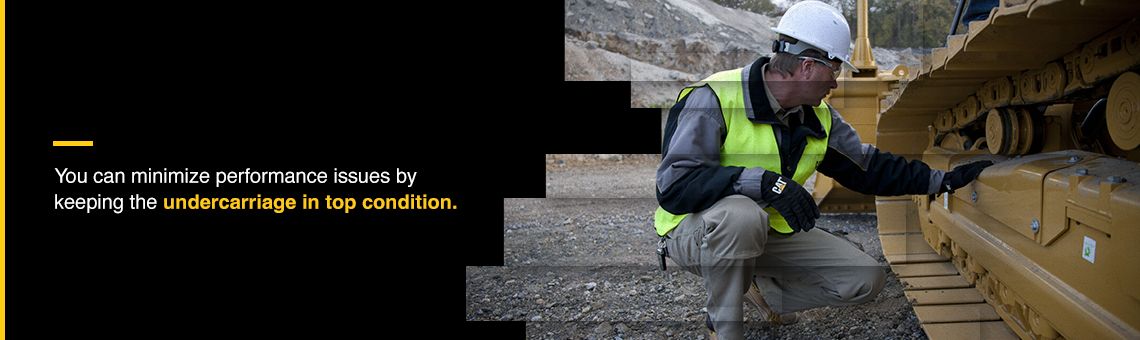

- Improved performance: If your undercarriage is worn or dirty, it may struggle to perform the same tasks it normally does. You can minimize performance issues by keeping the undercarriage in top condition.

How Do You Measure Undercarriage Wear?

There are several ways to measure the wear on the undercarriage of a piece of equipment. Most of these methods involve taking measurements and comparing them to specifications listed in your manual. Some vehicles also include handy, easy-to-access panels that display these measurements. To get most of these numbers, you'll need a tape measure, depth gauge and a few different caliper tools.

1. Visual Inspection

The simplest way to spot wear is through a visual inspection. Look for things like:

- Clear damage and dents

- Bent track pads

- Leaks

- Wear to pins, bushings and sprockets

If pins and bushings have wear on their top half, they need to be turned. If the sprockets have sharp points, they are worn and ready for a replacement.

2. Individual Part Measurements

Another way to assess wear is to measure the undercarriage components:

- Roller: For roller measurements, use a caliper tool to measure the diameter at the widest part of the top rollers. Then, use a caliper tool with bent rods to measure the bottom rollers underneath the flange shield.

- Shoe: To take shoe measurements, you'll need a depth gauge and a ruler or tape measure. Find a level section and use your depth gauge between the shoes. You'll also want to record the shoe width.

- Idler: Use the depth gauge to measure the idler.

- Pin and bushing: For pin and bushing measurements, use the caliper tool on the bushing to find the diameter.

3. Pitch and Height of Rail

Operate the machine in reverse for a few feet to tighten the track. Then, find the distance across five of the pins. This will give you the pitch of the rail.

Underneath the track, place the bar of the depth gauge along the bottom of a section of rail and run the depth indicator post to the bottom of the shoe. This gives you the rail height.

4. Loose Tracks

Extend your measuring tape from the highest point of the front roller to the back. Then, find the center of the measuring tape and measure the distance between that point and the top of the track. There should be some sagging, but too much indicates a loose track that could come off. Check with the manual specifications to see where your track should lie.

Regularly Inspect Your Undercarriage

The undercarriage supports the whole machine, so checking it often is vital to keeping it in good condition. Inspect the undercarriage at the start and end of each day. If you're working in more aggressive environments, perform an inspection after each use.

Parts of the Undercarriage to Inspect

You'll want to check the same parts of the undercarriage as you would in a visual inspection. Those components include:

- Bearings

- Bolts

- The drive motor

- Idlers

- Rollers

- Pins and bushings

- Shoes

- Sprockets

- Track links

Aside from specific part health, keep an eye out for any cracks, dents, leaks, wearing or exposed cables.

How and When to Clean Your Machine’s Undercarriage

Since the undercarriage is low to the ground, it's particularly susceptible to problems with work site materials — like mud that gunks up the components or abrasive gravel that wears away at the tracks. If these materials remain in the undercarriage, they can weigh down the tracks, rub up against bolts and prematurely wear the entire system.

In addition, mud, debris and rocks can become dangerous if left alone. They could damage the machine, come loose and hurt workers or cause damage to the environment. It is important not to leave cleaning tasks for the next day. Materials can harden overnight, which adds to the weight and wear on the machine and can make it more difficult to remove.

Each day after usage, take a shovel or a stiff brush to the machine to get rid of large chunks of material. Use a power washer to blast away any buildup from the hard-to-reach places.

Create a Regular Maintenance Plan

Maintaining your equipment undercarriage is essential to keeping it in good condition. Create and stick to a maintenance plan that incorporates performing inspections, greasing parts, tightening bolts and belts and any other upkeep task your machinery requires.

Below are some other best practices for undercarriage maintenance:

- Visually inspect the entire undercarriage for missing parts, exposed wiring, cracks and dents.

- Check track tension and adjust it according to your environment and machine. Consult the equipment manual if you're unsure what the machine needs.

- Test drive the machinery and look for any performance issues.

Contact the Professionals for Your Undercarriage Needs

Knowing how to maintain your undercarriage can help you extend the life of your equipment and increase the safety of your worksite. Excavator undercarriage maintenance, alongside other heavy machinery maintenance, is a smart investment in your business materials.

Since undercarriages are integral to the value and condition of a machine, buying used equipment provides a unique advantage. When you know an equipment's history, you can be certain you're getting a good deal. At Cat Used, we carry extensive maintenance and repair records on much of our equipment, so you can buy with confidence.

If you have any questions about undercarriage care, equipment maintenance or used equipment, our experts are ready to help. Give your local Cat® dealer a call today for more information.