Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Author: Small Business Expert | December 18, 2023 | Topic: Used Equipment

As a project manager or construction business owner, you know that lowering costs directly impacts margins — with thinner margins, you enjoy increased profitability and can offer competitive prices to win contracts.

Many variables impact construction budgets, especially because construction can take years in some cases. Over that time, the economy and the cost of materials can fluctuate. As a result, you need to find ways to lower costs in areas you can control, which can involve anything from eliminating wasteful practices to optimizing workflows.

Are you looking for strategies for reducing construction costs? Explore seven key tips to reduce construction costs here.

1. Plan Properly With Value Engineering

Aim to cut costs right at the start of every project. Take your time when working through construction plans so you can identify potential issues and cost overruns before construction begins. Resolving expensive problems at the beginning will help you keep everything on track budget-wise.

In particular, you can use value engineering to reduce expenses, which is a systematic and structured approach to design. This strategy involves working with every stakeholder — architects, engineers and contractors alike — to locate process improvements and bring cost-saving ideas to the table. For example, you might consider reducing the scope of your project if it makes sense.

2. Look for Material Alternatives

Another tip to reduce construction costs is to explore using alternative construction materials. Aside from labor, construction materials will likely take up the largest portion of your budget, so your choices matter. In some cases, the cost difference between a traditional material and a secondary option can be considerable.

These materials can include recycled or repurposed materials, such as reclaimed wood and recycled steel. Another option for wood is to use engineered wood products like veneer lumber and orientated strand board. Additionally, prefabricated components can provide cost savings along with simple assembly.

3. Integrate Technology

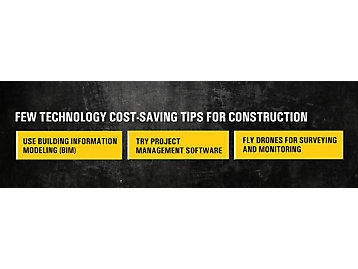

The strategic use of technology can streamline your operations. Let's look at a few technology cost-saving tips for construction:

- Use building information modeling (BIM): BIM allows you to create a 3D model of your construction project, taking out all the guesswork. As a result, you can plan more precisely, allowing you to adjust your budget so you only buy the materials you need. Plus, BIM can detect potential design conflicts before you start construction, which you can resolve to prevent headaches and save even more.

- Try project management software: These tools will give you real-time data and analytics you can use to improve your processes from the beginning of the project through to completion. For example, you can use it to allocate and track resources and complete collaborative budget tracking.

- Fly drones for surveying and monitoring: Consider employing drones for surveying and mapping purposes. These devices can help you gather data for use in the planning and design stages. You can also use drones to monitor hard-to-reach areas, helping ensure projects continue according to schedule so you can avoid costly downtime.

4. Partner With the Right Suppliers

Developing strong relationships with suppliers you can count on is one of the key ways to save costs. When you find a reliable supplier, do what you can to stick with them. This way, you can count on them to provide you with quality materials and equipment, and your relationship may lead to discounts and cost-saving advice in the future.

5. Reduce Excess Construction Waste

Did you know that construction waste accounts for 30% of waste produced globally? This waste is often contaminated with environmentally damaging materials such as paint, fasteners and adhesives. Practicing minimalism is a sustainable solution that can also help you reduce costs.

When ordering materials, be mindful of the quantities — underestimating how much you need can result in waiting for more orders to come and additional shipping costs, while overestimating the amounts may create waste. Look to future projects to determine whether you can reuse materials across jobs, which can simplify the ordering process.

6. Invest in Quality Tools

As you browse new tools to add to your team's toolkit, aim to invest in quality, durable products. These items will be more reliable, meaning they're less likely to break and malfunction, so you can use them longer without needing to replace them. Having an array of well-made tools can help you complete projects more efficiently, too.

7. Buy Used Heavy Machinery

If you're in need of equipment to help you complete future construction work, consider investing in used options from a reliable dealer like Cat® Used. This choice has many benefits for your business, including reducing initial costs, minimal depreciation, offering more selection and creating better contract flexibility. Overall, it could be your answer for how to reduce construction costs, as used equipment is often less expensive than new equipment.

When you browse used machinery, you can work with the dealer to understand each model's service history so you get a clear picture of its condition. In many cases, used equipment is just as reliable as old equipment — especially machinery from a trusted supplier. As a result, you can complete tasks with less worry about breakdowns, all while cutting costs.

Explore Cat® Used Heavy Equipment Today

Are you interested in a more affordable way to round out your heavy equipment fleet? Choosing used equipment can be your best option. By investing in well-maintained used equipment, you have more money to allocate to the rest of your budget.

Cat Used offers a high-quality selection of used heavy equipment for various construction tasks. Whether you're in need of mining equipment or machinery for agriculture, we can help you narrow down the best used option for your work. When you have questions or need maintenance support, our Cat dealers are here to help you every step of the way.

Browse our heavy equipment inventory to find the right solution for you. Interested in a model that isn't available yet? Sign up for email alerts to know when a piece of equipment you're looking for is in stock. Find a dealer near you today.