BETWEEN A ROCK

AND A HARD HAT

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- Self-propelled all-terrain system used for precise high-speed delivery and placement of gravel, stone, sand, soil, compost and mulch.

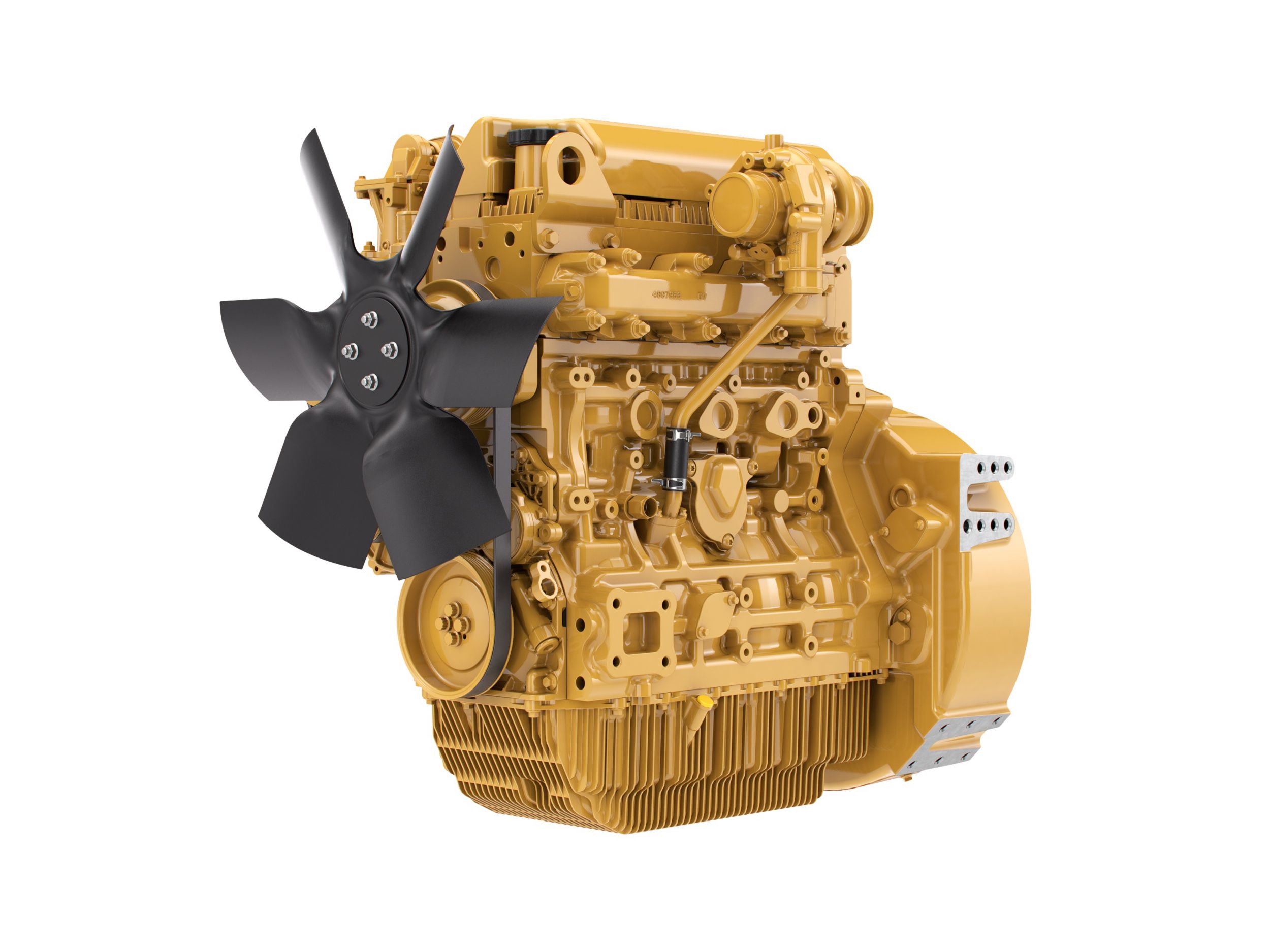

- Features the Cat® C4.4 engine offering 131 hp (98 kW) for maximum performance.

- The C4.4 is the ultimate compact engine solution perfect for tight-fitting engine quarters and easy to integrate into OEM equipment with minimum engineering time or cost.

- The C4.4 provides big benefits to end-users by reducing life-cycle costs with 3% DEF consumption and up to 20% lower fuel consumption compared to previous engines.

- Engine meets the latest US EPA Tier 4 Final and EU Stage V emissions requirements.

- The Cat dealer network offers one of the most extensive coverage networks across the globe with parts when you need them and how you want to get them with 24/7 online parts ordering access.

Cat® Engine Overview

- 4-cylinder, 4.4-liter engine available in power ratings from 110 hp (82 kW) to 200 hp (150kW) and peak torque 825 Nm (609 lb-ft)

- Industry-leading engine-mounted aftertreatment allows equipment manufacturers to remove cost and complexity from their engine installation

- Compact engine package is ideal for equipment manufacturers looking to downsize

- Engine technology advancements provide significant machine productivity benefits with 15% increase in power, 10% increase in torque and up to 5-10% reduction in fuel consumption*

- Aftertreatment upgrades ensure transparent regeneration so equipment performance is not impacted, delivering a service-free system and maximum uptime

*Compared to previous equivalent models

Compare Models

-

- Maximum Power

- 121 hp

- 90 kW

- Maximum Torque

- 369 lb-ft @ 1500 rpm

- 500 Nm @ 1500 rpm

- Emissions

- UN ECE R96 Stage IIIA, Brazil MAR-1

- UN ECE R96 Stage IIIA, Brazil MAR-1

C3.6

Learn More- Maximum Power

- 320 hp

- 240 kW

- Maximum Torque

- 935 lb-ft @ 1400 rpm

- 1268 Nm @ 1400 rpm

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

- U.S. EPA & CARB Tier 4 Final, EU Stage V

C7.1

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

Stone Slinger OS7 Truck-Mounted Conveyer

LOCATION:

St. Jacobs, Ontario

SCOPE OF ENGINE USE:

Cat® C4.4 Industrial Engine, US EPA Tier 4 Final, EU Stage V

CAT DEALER:

THROWING STONES

W.K. Dahms Mfg. Ltd. has been manufacturing the Stone Slinger™ truck conveyor system for more than 43 years and continues to set the standard for efficient delivery and placement of aggregate materials. The original Stone Slinger design was an innovation of W. Keith Dahms, who fitted a truck body with an outboard rear conveyor to replace the wheel-barrow method of distributing material on construction sites.

Today, the company is still family owned and operated. They produce an array of Stone Slinger equipment for precise, high-speed placement of gravel, stone, sand, soil, compost and mulch. Its latest innovative offering is the Stone Slinger OS7 machine. Unlike traditional Stone Slinger units, which are truck-mounted, the OS7 is a self-propelled all-terrain system designed to stay on a jobsite and place hundreds of tons of material until a project is done. The machine is loaded from onsite stockpiles so that it can place material continuously throughout each workday. The OS7 also has increased hydraulic capabilities compared to truck-mounted Stone Slinger units – it will throw stone up to 130 feet in distance, and an average offload of four tons per minute.

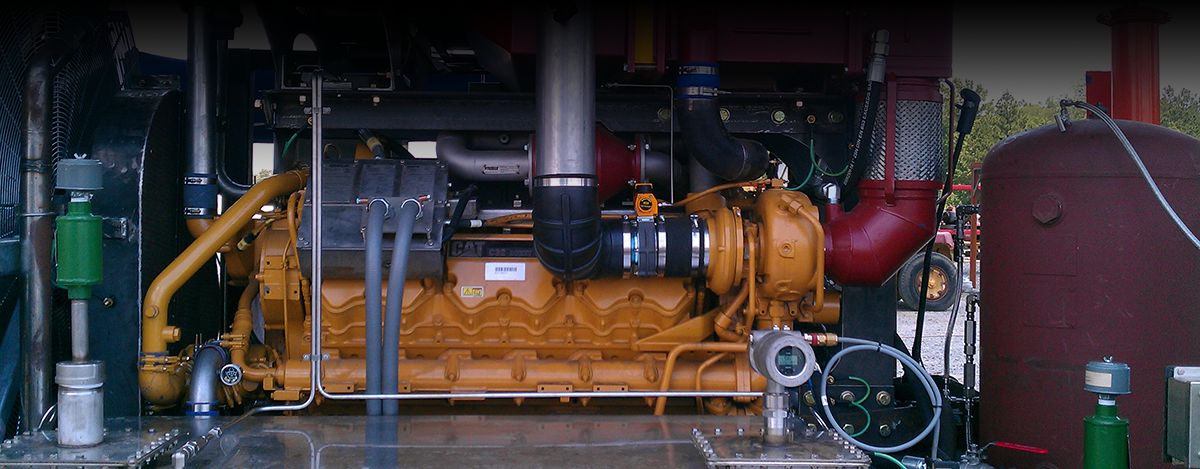

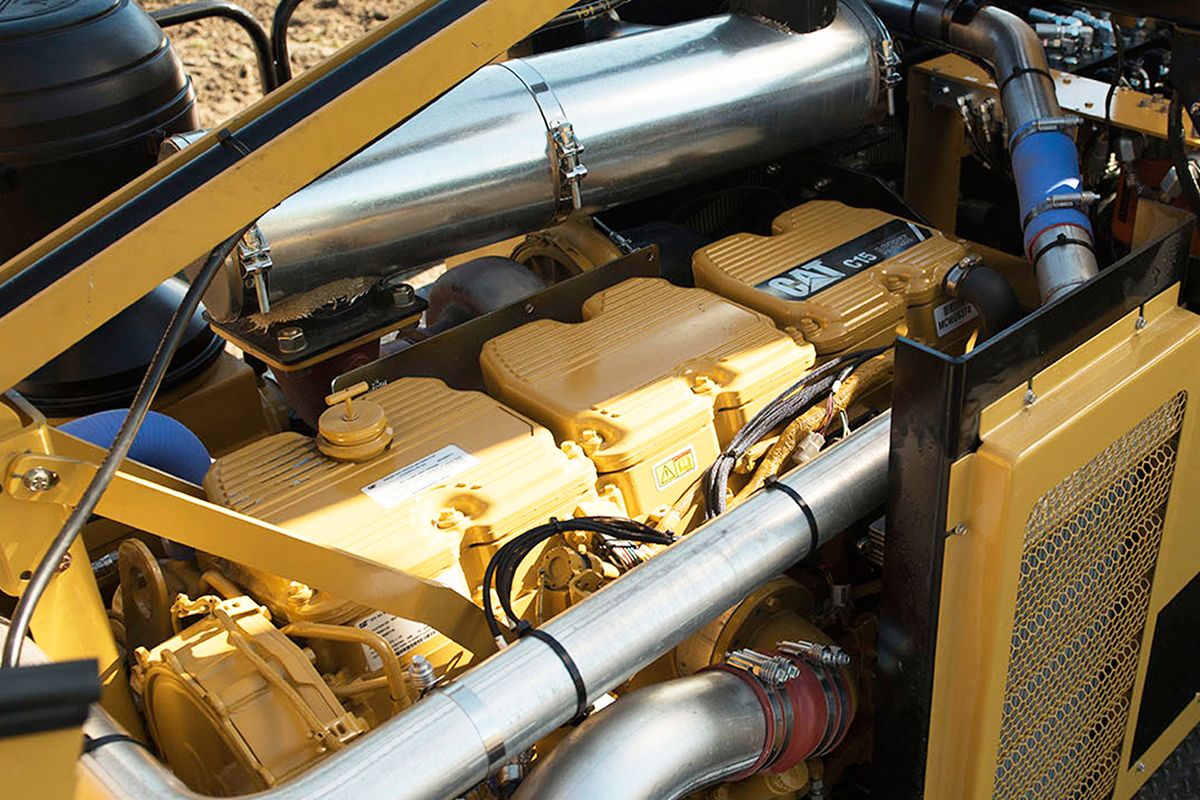

A Cat® C4.4 industrial engine powers the machine’s hydrostatic drive, and operators use a handheld control system to drive and steer the OS7, operate the conveyor and unload material.

Keeping a low profile

One of W.K. Dahms’ main objectives was to make the OS7 machine sit as low as possible, allowing it to be easily filled with a skid-steer or wheel loader. That required a design with the engine placed beside the machine instead of underneath the loading belt. However, the company knew this design would leave minimal room for the drive and unloading system, and so it sought an engine with a narrow width.

“We also knew we had to make the leap to Tier 4, but the idea of doing that was intimidating,” Todd Nelson says. Therefore, he turned to Cat dealer Toromont Cat for assistance. Toromont experts worked closely with Nelson, supplying helpful documentation, answering questions and guiding him through the process of specifying the C4.4 and integrating it into the Stone Slinger OS7.

Right engine. Right design. Featuring an engine-mounted aftertreatment, the C4.4 is the ultimate solution for tight-fitting engine quarters. In fact, Nelson says the C4.4 was pivotal for completion of the OS7 model’s wider, lower-sitting profile. “The compact width of the C4.4 engine is what really helped us out with the design of our new machine,” he remarks, noting the machine’s loading height is just slightly over six feet to accommodate smaller-size loaders. Furthermore, with an overall height of only nine feet, the OS7 can fit through a standard overhead door to place material inside a building – a big benefit for many customers.

The benefits keep piling up. This updated engine helps end-users save big by reducing lifecycle costs, thanks to 3% DEF consumption and up to 20% lower fuel consumption compared to previous versions. “Plus, it’s a nice selling point to say we have a Cat engine in the OS7 machine, because the Cat brand is synonymous with high quality and performance,” Nelson states.

“THE COMPACT WIDTH OF THE C4.4 ENGINE IS WHAT REALLY HELPED US OUT WITH THE DESIGN OF OUR NEW MACHINE.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more -

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Diamond Products CC5049DC saw - Cat® C2.2 Engine

Learn more -

Eagle Crusher UltraMax® 1200-CC Crushing Plant - Cat® C9.3B Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Infrastructure Contractors/MTS 3630T Construction Tractor - Cat® C18 Engine

Learn more -

JBS Track-Pack Silage Bagger - Cat® C15 Engine

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

Mobile Track Solutions MTS 3630T and the 3630W - Cat® C18 Engine

Learn more -

Morooka USA MST2200VDR and MST3000VD - Cat® C7.1 Engine

Learn more -

Orchard-Rite LTD Inc. Monoboom & Bullet Tree Shaker - Cat® C4.4 Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

Paling Transporter - Cat® C13B Engine

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Rotochopper B-66L Grinder - Cat® C27 Engine

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

Wolfe Heavy Equipment Trenchers - Cat® C15 and C18 Engines

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more -

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION