Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Two Industry Heavyweights Teamed Up to Create the New CC6774DCV Walk Behind Saw.

Read profile

Product Overview

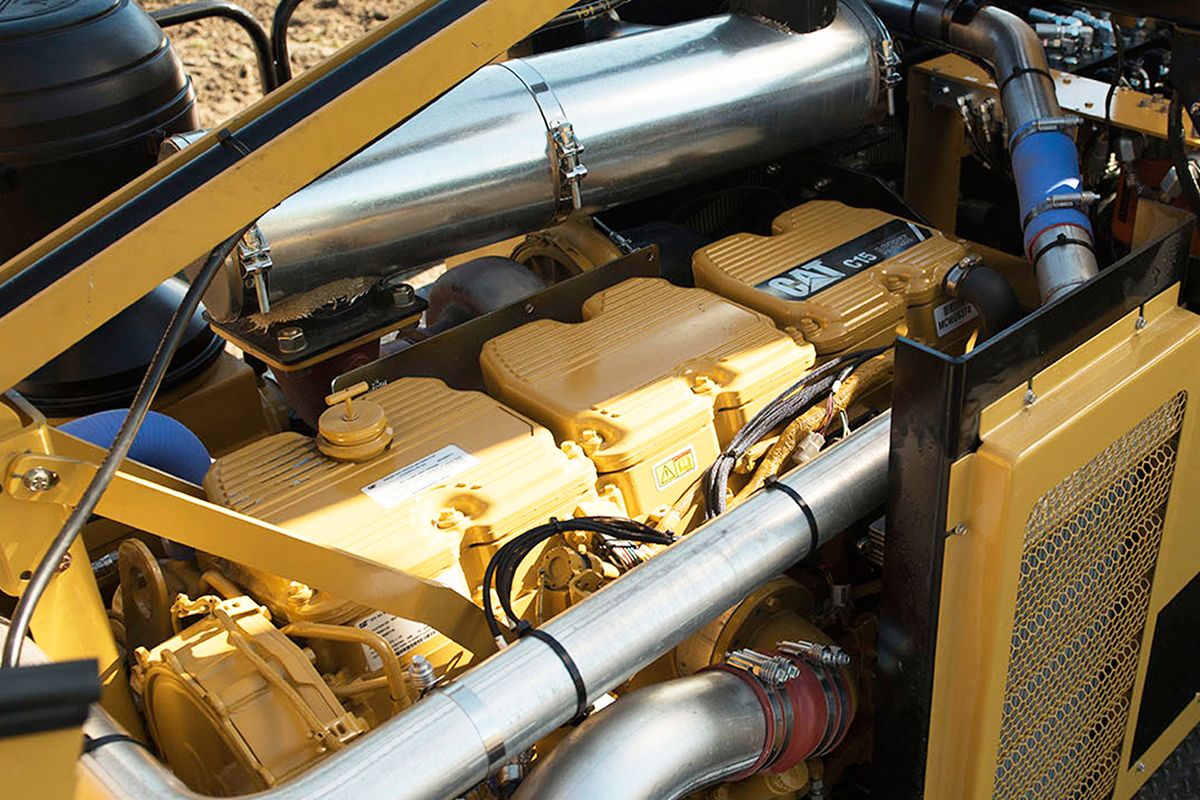

Cat® Engine Overview

Gallery

Related Profiles

POWER PROFILE

CUSTOMER:

Diamond Products

PRODUCT:

CC6774DCV Walk Behind Saw

LOCATION:

Elyria, Ohio

SCOPE OF ENGINE USE:

Cat® C2.2 – 55 kW (EU Stage V)

CAT DEALER:

Ohio Cat

Diamond Products is one of the largest diamond tool and equipment manufacturers in the United States. For over 50 years, it has designed and built tools to take the construction industry to new heights, and the company does not rest on its laurels.

Diamond Products has recently unveiled the CC6774DCV Walk Behind Saw as the next generation of the company’s highest volume model, the CC6571D. While the CC6571D is a popular machine, Diamond Products wanted to better serve customers in the construction industry with a walk behind saw with a Stage V engine and more horsepower.

More torque and more sustainability.

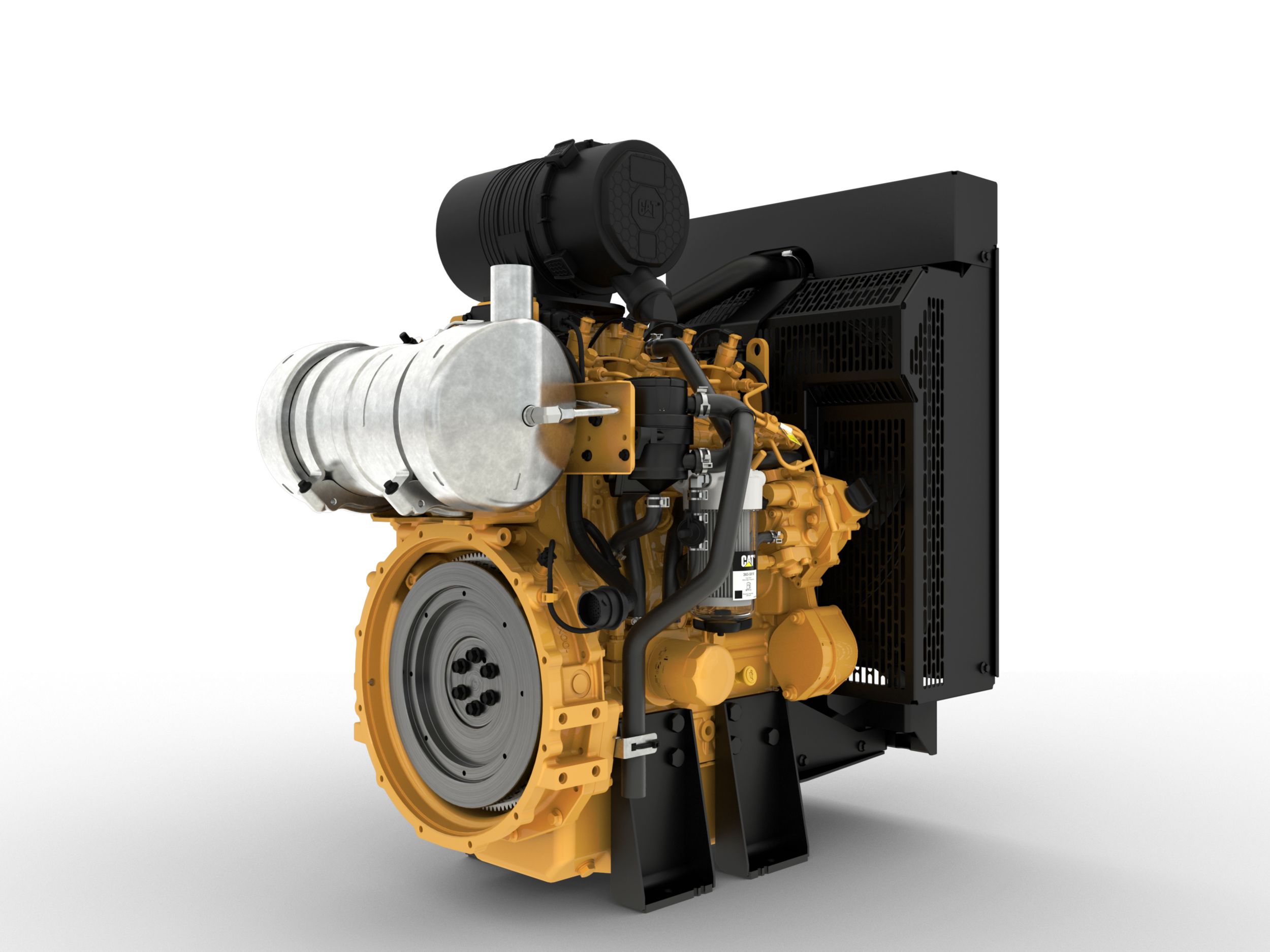

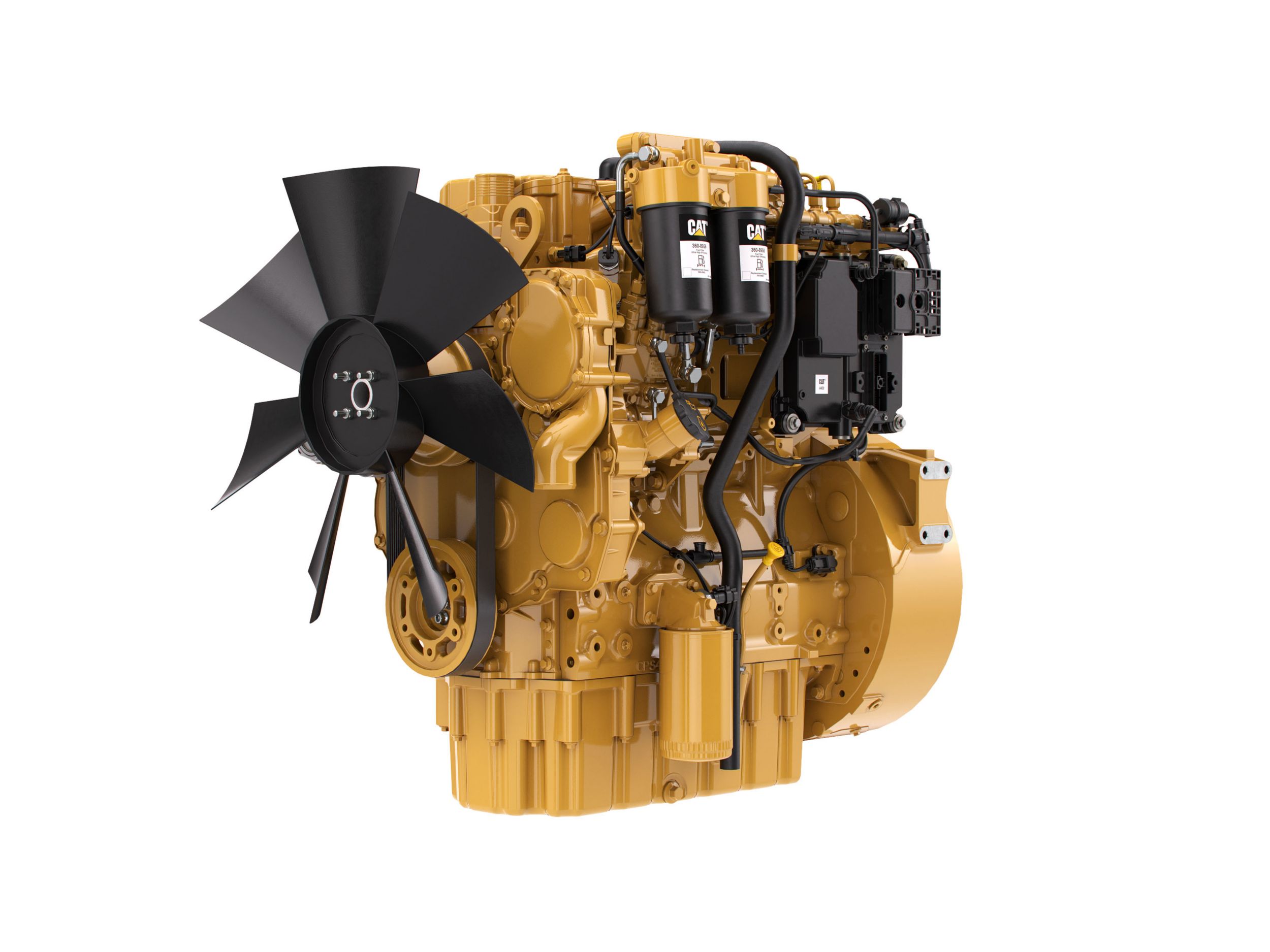

Adding power to construction equipment is a delicate balance. Engineers want to increase horsepower without sacrificing efficiency or increasing equipment size. Diamond Products chose to equip the CC6774DCV with a Cat® C2.2 EU Stage V/U.S. EPA Tier 4 Final IPU Engine. The compact size and power density of the engine was the biggest factor in choosing this power source, making the CC6774DCV more sustainable with reduced emissions.

The engine wasn’t the only upgrade. The CC6774DCV utilizes Kevlar belts, which increase torque-carrying capacity by up to 50%. The rear propulsion is also improved. The design included replacing the hydrostatic transmission and geared axle with dual hydraulic motors.

“We want to ensure operator safety and don't want to see our blades over-spun, so we added blade speed regulating software.” — Miki Pavlovic, Director of Quality and Engineering, Diamond Products

Diamond Products added blade speed regulator software to the CC6774DCV Walk Behind Saw to prevent operators from over-speeding the blade. “It simplifies the user interface,” says Miki Pavlovic, Director of Quality and Engineering at Diamond Products. “We have a single-speed and a three-speed version. Both have blade shaft speed sensors that can safely govern and maintain the speed of the blade.”

The CC6774DCV features optional Cat Connect technology to help construction businesses improve machine uptime and increase overall productivity. Electronic depth indication allows an operator to know precisely how deep they’re cutting while in action. This is an upgrade from the previous saw model that used a mechanical indicator.

Adjusting for compact power.

Diamond Products stays in tune with their customers. Knowing construction businesses and utilities need to haul a lot of equipment to a jobsite, Diamond Products focused on creating a walk behind saw that was both compact and powerful. The CC6774DCV Walk Behind Saw has enough power density to get the job done but doesn’t take up too much space. The Cat C2.2 Stage V IPU engine fits the bill to provide power in a limited space.

“It’s all about space. The CC6774DCV saw is often used for highway and road construction. That’s a dangerous place to work, and you want to keep the operator as far from traffic as you can. We try to make it as compact as possible for that reason.” — Miki Pavlovic, Director of Quality and Engineering, Diamond Products

The shorter frame length and a simple design make the CC6774DCV Walk Behind Saw unique to the industry. It’s easier to maintain than most larger saws. Some smaller or mid-sized saws have a similar design, but the CC6774DCV provides more power.

A powerful companion.

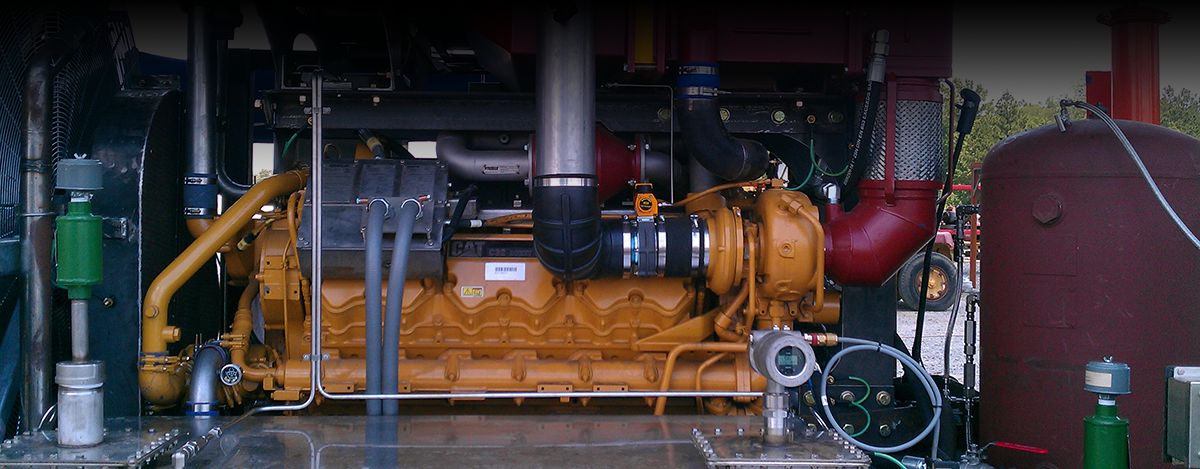

When development began for the CC6774DCV in March 2022, Ohio Cat was there to help with the engine installation and to make sure the power source would be sufficient. This collaboration was beneficial to both sides. “Their engineers are sharp,” says Ohio Cat Industrial Engine Sales Representative Matthew Abahazi. “When Diamond Products engineers come to the table asking questions, they’ve done a considerable amount of homework prior, and I’m really just putting icing on the cake. They’re really thorough.”

All the hard work and planning paid off. The development process for the CC6774DCV took about 12 months, with Diamond Products now taking orders for the new saw.

“We’re really excited about this project, taking one of our best-selling saws and upgrading it. There’s an opening price point option and a lot of features that can be added based on the user preferences and application.” — Miki Pavlovic, Director of Quality and Engineering, Diamond Products

PRODUCT OVERVIEW

Diamond Products chose to equip the CC6774DCV with a Cat® C2.2 EU Stage V/U.S. EPA Tier 4 Final IPU Engine. The compact size and power density of the engine was the biggest factor in choosing this power source, making the CC6774DCV more sustainable with reduced emissions.

The CC6774DCV utilizes Kevlar belts, which increase torque-carrying capacity by up to 50%. The rear propulsion is also improved. The design included replacing the hydrostatic transmission and geared axle with dual hydraulic motors.

Diamond Products added blade speed regulator software to the CC6774DCV Walk Behind Saw to prevent operators from over-speeding the blade. It also features optional Cat Connect technology to help construction businesses improve machine uptime and increase overall productivity. Electronic depth indication allows an operator to know precisely how deep they’re cutting while in action. This is an upgrade from the previous saw model that used a mechanical indicator.

CAT® ENGINE OVERVIEW

The Cat® C2.2 IPU is available as a turbocharged or turbocharged aftercooled, common rail direct injection engine meeting EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 (Tier 4 Final) emission standards. For ease of installation, the IPU provides full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounted air filter.

Fully integrated from the factory, with aftertreatment and air filter ready-mounted to the IPU, the C2.2 offers a wide range of options to suit your application in agriculture, material handling, construction, mining, aircraft ground support, and many other industries.

World-class manufacturing capability and processes, coupled with proven technologies, offer 10% more power and 30% improvement in peak torque over the previous generation turbocharged C2.2. This allows you to downsize, saving installation space on your products, saving you engineering development time and costs.

Compare Models

-

- Maximum Power

- 134 hp

- 100 kW

- Maximum Torque

- 406 lb-ft @ 1500 rpm

- 550 Nm @ 1500 rpm

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

- U.S. EPA & CARB Tier 4 Final, EU Stage V

C3.6

Learn More -

- Maximum Power

- 142 hp

- 106 kW

- Maximum Torque

- 411.2 lb-ft @ 1400 rpm

- 558 Nm @ 1400 rpm

- Emissions

- China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

- China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

C4.4

Learn More

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

Allmand Maxi-Lite Tower - Cat® C1.1 Engine

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more -

Barco Pump - Cat® C2.2 and C3.6 Engines

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

Chip and crush waste with Rotochopper

Learn More -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Diamond Products® CC4948DC saw - Cat® C1.7 Engine

Learn more -

Diamond Products® CC5048DC saw - Cat® C2.2 and C1.7 Engines

Learn more -

Diamond Products® PC1505XL Pavement Grinder & Groover and PC6004EC Grinder

Learn more -

Diamond Z Tub and Horizontal Grinders

Learn more -

Do more with Wetland Equipment Company and Cat.

Learn More -

Doosan Portable Power Large Air Compressors

Learn More -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Global Pump 12GHH

Learn More -

Gorman-Rupp Cat Powered Pumps

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

HPSI Model 500 Vibratory Hammer

Learn More -

How Cat and S&S Metal Fabrication fix harvesting

Learn More -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Infrastructure Contractors/MTS 3630T Construction Tractor - Cat® C18 Engine

Learn more -

LMR Landfill Tippers – Powered by Cat® Reman

Learn More -

Mobile Track Solutions MTS 3630T and the 3630W - Cat® C18 Engine

Learn more -

Mobile Track Solutions connectivity - Cat® C18 Engines

Learn more -

Morooka MST880VDL and MST880VD

Learn more -

MudPuppy Pumps - Cat® C7.1 Engines

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

Pioneer Pump Four-Inch and Six-Inch Pumps

Learn More -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Supreme Blasting Power from Sullair

Learn More -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

Trenching Through the Toughest Terrains with Trencor

Learn More -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

Vermeer terrain leveler - Cat® C18 Engine

Learn more -

Xtreme Polesetter II Digger and Bucket

Learn More -

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.